HARDWARE

SOFTWARE

CONSUMABLES

BUSINESS

CURRENT TRENDING NEWS

- Landa plans expansion with new ink plant in North America

- ReTac Textures film used for Alice in Wonderland wall graphics

- Agfa launches next-gen Hybrid Anapurna H3200 inkjet printer

- printMAX retains title as Roland's most successful UK dealer

- Industry shaping technologies to be unveiled by Ricoh at FESPA

Tags

Roland DG

-

Mimaki brings digital innovation to promotional products at PSI 2017

10 Dec 2016

Mimaki, a leading manufacturer of wide-format inkjet printers and cutting systems, today announced that it will be heading to Messe Düsseldorf for PSI 2017.

-

Mimaki highlights textile opportunities for home & fashion at Heimtextil 2017

7 Dec 2016

Mimaki has announced that it will have a significant presence at Heimtextil 2017, scheduled for 10th to 13th January at Messe Frankfurt in Germany.

-

SENFA set for expansion of Decoprint Pearl range

5 Dec 2016

SENFA, the Alsace, France-based Technical Textiles division of the Chargeurs Group, is well known for its Decoprint Pearl premium fabric for backlit display applications. However, in recent months, the company has renewed its focus on expanding its range of Decoprint textiles to meet the ever-growing needs of its global customer-base.

Since its introduction in 2004, Decoprint Pearl has become a world leading fabric for backlit display applications installed in lightboxes in retail outlets, shopping malls and airports all over the world. The smooth finish, the perfect diffusion of light, the excellent white point and – of course – all the necessary fire certifications, renders it the number one choice for many international brands.

The advantages of textile graphics are numerous: Being PVC-free, they are more environmentally-friendly; They are also lighter in weight, so cheaper to transport and easier to install; Most of all though, they often simply look better than prints produced on other types of media.

In its original format, SENFA Decoprint Pearl is ideal for solvent, ecosolvent, latex and UV-curable printing technologies. However, SENFA Decoprint’s R&D department has recently been busy developing and expanding the Decoprint Pearl range of products to meet specific requirements.

In 2015, SENFA introduced Decoprint Pearl TR for transfer sublimation printers which added a non-stick ingredient to the coating to enable the smooth passage of the textile through the calender.

Earlier this year, the company launched Decoprint Pearl Soft, with increased crease resistance ensuring even more trouble-free handling, finishing and packing for printers and installers alike.

Development of the Decoprint Pearl product line doesn’t end there though and there are plenty of exciting new products being lined up for launch in 2017. Blaise Humphries, Decoprint's business unit manager, explains: “Our Pearl range of products is being continually expanded to meet the ever-growing needs of our customers, and we’ve several exciting new products in the pipeline set for launch in the new year!”

For further information on SENFA Decoprint, please visit www.decoprint.eu/en.

-

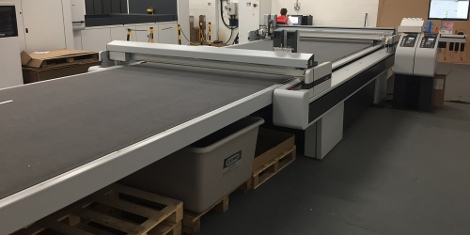

Caps Cases has sights on POS & bespoke packaging with Zünd D3 investment

5 Dec 2016

Caps Cases says it plans to expand into new areas including the point-of-sale (POS) and bespoke packaging sectors.

-

Mimaki to feature innovative solutions at FESPA Eurasia

4 Dec 2016

Mimaki will present its leading range of solvent, textile and UV printers, designed to address key print production needs, on two booths at FESPA Eurasia.

-

i-Sub offers free Digi-Foil system with Mimaki UJF-3042/UJF-6042 MkII printer orders

30 Nov 2016

i-Sub Digital has announced it will be giving away a free Digi-Foil DF system with every Mimaki UJF-3042 MkII and UJF-6042 MkII printer order placed before 22nd December 2016.

The UJF-3042 MkII and the UJF-6042 MkII printers feature print speeds 20% faster than their predecessors, making them the perfect choice for sign and display companies seeking more productive and profitable ways to conduct business. They can print using a range of different inks, supporting a very wide range of applications with varying levels of abrasion resistance and flexibility up to 170%.

With Mimaki’s PR-200 inkjet primer, printing on substrates normally considered beyond the reach of UV-printers is possible, including glass, metal and resins, and Mimaki Clear Control (MCC), a clear varnish ink, can be used to both highlight areas with spot or flood coating and deliver embossing with multiple passes.The UJF-3042 MkII and UJF-6042 MkII have the ability to print on objects up to 153 mm thick. Advanced functionality provides a print table that moves during printing to reduce vibration, delivers precise dot placement and enables high quality printing on a wide range of objects and materials. Operators can preset Mimaki Expand Color in the printers’ RasterLink digital front end for upgraded colour representation with more vibrant, solid colour and brighter tones.

Mimaki Circulation Technology (MCT) circulates the White inks at regular intervals to ensure consistent solid White printed results. The printers’ fully enclosed print table improves safety while also keeping dust and other contaminants out of the system.

The UJF-3042 MkII and UJF-6042 MkII printers are fully compatible with the i-Sub Digi-Foil DF system, exclusively available from i-Sub. Offering outstanding foiling effects onto virtually any material by skilfully blending traditional craft techniques with state-of-the-art technology, Digi-Foil delivers a vibrant range of digital foils that produce stunning quality finishes on virtually any substrate and offer foil effects identical to traditional foiling but faster and more cost-effectively.

Presentation boxes, packaging (short run and proofing/mock-ups), promotional items, gifts, trophies and leather goods will benefit from the Digi-Foil touch, as will folders, control panels, phone cases and tablets or PCs. Almost every printable substrate can be given that luxurious foil effect quickly and easily.

Digi-Foil's extensive range includes the following effects and finishes:

• Silver

• Gold

• Coloured metallics

• Woodgrains

• Holographic

• Watermarks

• Security marking

• Opaque

• Patterned, and many, many moreWith the ability to produce various finishes such as stippled, gloss or matt and the option to over-varnish on the Digi-Foil areas − or the whole printed area − the potential applications are endless and open up a whole new range of profitable and productive business opportunities.

Delivering superior productivity, quality and flexibility the UJF-3042 MkII and the UJF-6042 MkII are the latest generation of UV flatbed printers from Mimaki. Priced from just £20,995, purchasers enjoy added value when they buy from i-Sub, including flexible finance options and trade-in offers on previous UJF models. Plus the incredible Digi-Foil DF system is completely free on orders for the UJF-3042 MkII and UJF-6042 MkII printers placed before 22 December 2016.

Visit http://i-subdigital.com/mimaki-ujf-6042.html or call +44 (0)1536 415511 for more information.

-

QPS celebrates five years of end-to-end ink cartridge recycling scheme

29 Nov 2016

At a time when recycling is making headlines, Quality Print Services (QPS) is celebrating five years since the launch of its cartridge recycling scheme.

QPS introduced the free programme for its customers in 2011 – long before the 5p carrier bag charge was introduced and campaigns began to call for coffee shop chains to recycle their cups.

The end-to-end cartridge recycling programme was developed in partnership with ink brand Nazdar to minimise the signage and graphics industry's generation of landfill waste and its environmental effects. QPS began collecting empties when delivering new ones or while visiting customers as part of its renowned printer service support.

To further reduce road miles, the recycling process is kept local to QPS's HQ in Burscough, Lancashire. Any remaining ink goes to a nearby solvent recovery centre while separated cartridge components are sent to a reprocessing plant in the north of the county, where they are ground down and reprocessed into clean chips for resale to UK plastics manufacturers.

In the past twelve months alone, QPS has collected around 3.5 tonnes of plastic cartridges and saved them from going to landfill.

As well as reducing their environmental impact, this means QPS's customers don't have to worry about disposing hazardous materials or finding space to store their empty cartridges as they build up.

"Five years after launching our ink cartridge recycling programme we remain one of the only suppliers to offer this service to our customers," says Chris Bailey, Director, QPS.

"More and more print buyers are demanding environmental action from their print providers and we can offer help in this area free of charge. What's more, our customers who sign up for the recycling programme will receive certification of their involvement, which can help support an application for ISO 14001."

He adds: "Our industry creates a vast amount of waste, far too much of which ends up in landfill. It's up to all of us to help reduce that, but we make it as easy as possible for our customers."

QPS also champions British business – the majority of the Nazdar wide-format ink it sells is made in the UK – so is proud to contribute to the British circular economy by providing recycled plastic chips for re-manufacturing into new products.

All QPS customers who take regular deliveries of Nazdar ink cartridges are eligible for the programme. For more information about the campaign or QPS's large-format print products and services, please email sales@qualityprintservices.com or call + 44(0)1704 897575.

For more information on Nazdar and its comprehensive range of ink solutions, please visit www.nazdar.com.

[Picture caption: Used Nazdar ink cartridges are turned into plastic chips for remanufacturing]

-

Sign & Digital UK reveals exciting exhibitor line-up for 30th anniversary show

28 Nov 2016

Sign & Digital UK has announced the current exhibitor line-up for its 30th anniversary event, which returns to the NEC in Birmingham from 28 to 30 March 2017.

Next year’s show is looking to welcome a growing number of new exhibitors from the sign making, display solutions and digital printing industry, including A.P.A. UK Ltd, BODO Industrial, Color Master Digital Materials, Universal Laser Systems, UK MetalCraft Ltd, Marqetspace, printing.com, DTP Supplies and Unisign Flex.

Exhibitors returning to Sign & Digital UK 2017 after a very successful show earlier this year include: AG/CAD, Antalis, Award Crafters, Biesse, Blackman & White, Epson, Grafityp, Granthams, Graphic Printing Technologies, Graphtec GB, Hewlett Packard, Hexis UK, Hybrid Services/Mimaki, Innotech, Perfect Colours, printMAX, Resolute DTG, Roland DG, Route 1 Print, Signmaster Systems, Signwaves, Soyang Europe, The Magic Touch, Ultima Displays, Vivid Laminating Technologies and Your Print Specialists.

Sign & Digital UK 2017 also includes the return of companies who didn’t exhibit at the 2016 exhibition. These are Digiprint Supplies, Atlantic Tech Services, Eurobond Adhesives, Russell & Chapple, CR Clarke & Co (UK) Ltd, Caldera, Photocast Products, Innova Solutions and Spandex.

Event director, Rudi Blackett said: “We’re celebrating 30 years as a national exhibition in 2017, so it’s really pleasing to see such an innovative and diverse line-up of exhibitors, especially with 4 months still to go until the show opens.

“Sign & Digital UK is an established and trusted part of the trade calendar – a place to do business. The focus for 2017 is on Applications, Ideas and Advice, so visitors can be sure of discovering the latest products and services from hundreds of leading suppliers. Not only that, but there’s great advice on offer from experts on stands and in the free seminar theatres, plus the chance to see live demonstrations of equipment and skills.”

Sign & Digital UK 2017 takes place at the NEC, Birmingham from 28 to 30 March 2017 and is free to attend for visitors. To enquire about exhibiting please contact the show team on 01342 332 000, email signanddigitaluk@fav-house.com or visit www.signanddigitaluk.com

-

Epson to demonstrate latest digital textile printing solutions live at Heimtextil 2017

27 Nov 2016

At Heimtextil (10th to 13th January 2017, Messe Frankfurt), Epson will demonstrate its most advanced range of digital textile printers developed to meet the professional textile market’s demand for flexible, cost-effective and sustainable production solutions. From entry-level, short-run digital printers to high-end, production-level systems, Epson delivers a choice of solutions that combine superb engineering, Epson Micro Piezo printheads and dedicated inks.

For the first time at Heimtextil, Epson will show the innovative Monna Lisa® digital production printer. Over the last 10 years, the Monna Lisa has revolutionised the digital textile printing market by moving it from the pioneering phase of sampling to reliable full-scale production. Manufactured by Robustelli with Epson printheads, and using Genesta® inks designed by Epson in cooperation with For.Tex, the Monna Lisa is a unique Total Solution for the professional textile market. Available in three print widths (180, 220 and 320 cm), it gives users the advantage of reduced production times, the ability to print customised designs on any fabric and low-cost sampling flexibility.

Today over three million square meters of fabrics are printed with Genesta pigment inks: at Heimtextil the 160cm Monna Lisa T16 model will be using eight-colour Genesta pigment inks to print onto natural fabrics for a variety of home textile applications. Visitors will see quality printed fabrics with high chromatic accuracy, reproducibility, resistance and colour fastness. In addition, because printing on the Monna Lisa with Genesta pigment inks requires no steaming or washing, it is a very eco-friendly process and meets the industry’s increasing focus on sustainable production techniques.

Epson will demonstrate the affordable and easy-to-use SureColor SC-F9200 64-inch model from its SureColor range of dye-sublimation printers. This highly flexible machine is ideal for producing small-to-medium volumes of high-quality textiles and for sublimating bespoke designs onto hard substrates such as splash backs, table tops, mugs, cutlery, vases and coasters. A four-colour printer, using UltraChrome DS ink with high density HDK Black, the SC-F9200 features dual Epson’s PrecisionCore TFP printheads to ensure consistent and reliable results with superb colour and clarity. Visitors to the stand will also see the desktop Epson SureColor SC-F2000 direct-to-fabric printer in action producing a variety of T-towels, aprons, cushions and tote bags on-demand and in minutes.

Epson works closely with textile designers and colleges around the world to explore the power of digital printing within the fashion and décor industries. For Heimtextil, the company has teamed up with four young European textile designers from its ‘Design for Living’ initiative to showcase the flexibility and potential of digital printing to create a variety of textile products. The stand will feature a customised design from one of these student designers implemented across multiple fabrics and homeware products to showcase the considerable freedom and opportunity that Epson and Robustelli technology gives to designers and manufacturers.

Giovanni Pizzamiglio, Head of Pro-Graphics Sales, Epson Europe, says: “Choice and customisation is what the home textile industry wants today and Epson’s highly versatile dye sublimation and direct-to- natural fabric printers are designed to meet this demand. The significant range of wool, linen, cotton, silk and polyester-based fabrics that can be printed, combined with the latest in Epson digital textile printing technology, means that it is now possible to reproduce high quality, vibrant and durable designs in any volume. Our aim is to give designers, manufacturers and retailers the ability to produce quality, bespoke textile products cost-effectively and quickly to meet fast-changing market trends.”

Epson will be found on Stand C10, Hall 6.0.

[Photo caption: The Monna Lisa direct-to-textile digital production printer]

-

Drytac boosts European sales team with appointment of Marc Hansing

23 Nov 2016

Drytac Europe, an international manufacturer of self-adhesive materials for the print, label and industrial markets, has announced the appointment of Marc Hansing to the role of Sales Account Manager.

-

Mimaki Tx300P-1800 direct-to-textile printer proving to be a 'fashionable choice'

23 Nov 2016

Following its unveiling during ITMA Milan, the Mimaki Tx300P-1800 has put the manufacturer at the forefront of direct-to-textile printing bringing a flourish of UK and Irish installations of this versatile new printer.

Mimaki’s UK & Ireland distributor, Hybrid Services, has seen strong uptake of the Mimaki Tx300P from both the education sector and within the textile printing industry, as the company’s National Sales Manager for Textile and Apparel, Stephen Woodall explains: “The Tx300P-1800 is flying since its launch and we’ve made significant sales resulting in stock shipping out as soon as it arrives in our warehouse. We’ve been busy installing Tx300s into various educational institutions for the start of the new academic year who have waited patiently for the right printer to upgrade their existing Mimaki TX2 printers, and with the product now shipping with competitively priced pigment, reactive, disperse and dye sublimation inks, we envisage this to continue into 2017 and beyond.”

The Mimaki Tx300P-1800 inkjet printer is ideal for printing high quality output on all types of fabrics, including thicker and textured materials. This is made possible as the print-head height is adjustable from 2-7mm. The increased speed at which the ink droplets are fired also ensures accurate ink placement with the high head gap. The Tx300P is designed as an entry-level model and with its compact footprint, fits perfectly in places with limited floor space, such as design studios or school facilities.

“Mimaki’s 4 colour pigment inks are proving superior to any alternatives on the market in terms of colour gamut, which will be further enhanced with the release of an 8 colour set by the end of the year,” continues Woodall. “Independent reseller tests have shown that their wash fastness and abrasion resistance is industry leading and this, coupled with print speeds of up to 68m² per hour, are making the Tx300P an attractive proposition.”

Customers can arrange a demonstration of the Mimaki Tx300P-1800, or any of Mimaki’s other products, at Hybrid’s showroom by telephoning +44 (0)1270 501900. Additionally, an extensive selection of Mimaki Textile & Apparel products are available to view across the UK and Ireland through Hybrid’s specialist Textile and Apparel resellers. Further information can be found by visiting www.hybridservices.co.uk.

-

HP technology brightens the walls at Alder Hey Children’s Hospital Unit

22 Nov 2016

HP has announced that it has created and donated a series of wall graphics for the Clinical Research Facility at Liverpool’s new Alder Hey in the Park Children’s Hospital.

-

Duggal offers brands new creative possibilities with HP Indigo 12000 Digital Press

18 Nov 2016

HP announced that Duggal Visual Solutions has installed the HP Indigo 12000 Digital Press in the heart of New York City.

-

SENFA Decoprint: a European success story made in France

16 Nov 2016

SENFA Decoprint is probably one of the biggest companies you’ve never heard of. However, all that is about to change as the France-based manufacturer – part of the Chargeurs Group – sets its sights on further expanding its operations throughout Europe, the Americas and beyond.

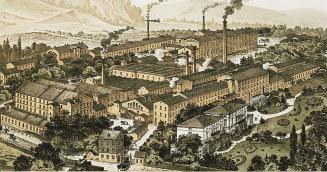

Most people involved in large format digital printing know that the area around the Lake Como in Northern Italy is a historical centre of textile activity. It is less well known that just a three-hour drive north, across the Alps, there is another textile centre of excellence in the picturesque valleys of Alsace, Eastern France.

Since the industrial revolution, knitting, weaving, dying and sewing have been the cornerstone of countless communities. From the mid-19th century, mills were being powered by hydro-electrical turbines which were well ahead of their time (many of which are now being dusted down and revamped for a second life more than a century later). In Alsace – like other regions – benevolent businessmen built housing estates for their workers, and schools for their children, and generally the industrial climate was one where both workers and management appreciated hard work and just rewards.

The hard-working ethic and the constant search for excellence – combined with an ideal geographic location close to both Germany and Switzerland – enabled these communities in Northern France to thrive and to survive the initial financial and economic crises (and wars) of the 20th century. However, globalisation finally had an impact on these communities and gradually textile manufacturing moved initially to cheaper manufacturing bases in Europe and then further afield to North Africa and the Far East. One by one the mills and factories closed and it became clear that something special had to be done to survive.

SENFA Decoprint is an example of one such company that dug deep in this time of adversity and adapted the textiles it made to meet specific and often niche technical applications. Based in Sélestat, just south of Strasbourg, the historical activity of SENFA was coating interlining (the rigid part of shirt collars). As the garment industry declined in Europe it became obvious that it was time to diversify or die.

At around the same time in the late 1990s, large format digital printing was experimenting with printing onto textiles and it became clear that coated textiles were necessary for the ink to stick and dry. With its expertise in both textiles and coating, SENFA saw an opportunity and invested in a new purpose-built 3.2metre coating line in 2001 to diversify its core product offering to encompass wider widths.

In 2004, SENFA formalised its entry into the wide-format space by creating the Decoprint department to focus on the manufacture and coating of textiles specifically for the large format digital print market. The product line was diversified to incorporate other functions such as fire resistance, light diffusion, block-out and more, and over the years, SENFA developed a full range of printable Decoprint textiles – suitable for solvent, UV and latex print technologies – for visual display applications.

The initial adoption of textiles for visual display was slow but gradually the advantages of printing onto textiles made more and more sense to the marketplace: Textiles are free of PVC and are therefore much less damaging for the environment than vinyls or banners; they are lighter in weight, so cheaper to transport and easier to install; and finally – perhaps most importantly – they simply look better than many prints produced on other types of media.

Fast forward a few more years and SENFA’s flagship product - Decoprint Pearl – has become a world leader. It is a premium fabric for backlit applications installed in lightboxes in retail outlets, shopping malls and airports all over the world. The smooth finish, the excellent white point and of course all the necessary fire certification (M1, B1 etc.) renders it the number one choice for many international brands.

Boosted by the success of the product, in 2015 SENFA opened an €8 million, five-metre wide coating line to meet the ever-growing needs of its customers.

The product line doesn’t just stop at Decoprint Pearl. Year on year sales are growing at a healthy rate and SENFA has many new Decoprint products in the pipeline which it plans to bring to the wider market. For example, with more and more trade fair stands being built with printed textiles, SENFA has specifically developed a black-back range suitable for use with UV-curing, latex and sublimation technologies.

Blaise Humphries, Decoprint's business unit manager, explains that SENFA plans to further expand its international distribution network in 2017: "We will be concentrating on developing the North American market with the creation a US-based sales position from January 2017 and we will be employing a Spanish speaker to cover Central and South America. This follows the development of new channels in 2016 when we appointed distributors in India, Australia and South Africa. This geographic expansion will continue into 2017.”

He continues: “New markets and new applications are the backbone of SENFA's growth strategy. A renewed focus on interior decor and wall covering products should help our double-digit annual growth figures continue for the foreseeable future. The future looks very exciting for SENFA Decoprint"

Whilst the face of the textile industry in Alsace has changed, that hard-working ethic and constant search for excellence have remained constant. One thing is for sure: watch this space for future developments in printable textiles…

For further information on SENFA Decoprint, please visit www.decoprint.eu/en

-

Wilmot-Budgen doubles production speeds following Zünd D3 installation

16 Nov 2016

Wilmot-Budgen says it has doubled production speeds on two-sheet cutting processes following the installation of a brand new Zünd D3 XL3200 digital cutting table, combined with its existing Zünd Board Handling System.

-

HP issues call for entries in second annual HP Inkspiration Awards North America

11 Nov 2016

HP and Dscoop are partnering for the second annual HP Inkspiration Awards North America, a premier contest celebrating best-in-class print projects using HP Indigo, PageWide Web Press, Scitex or Latex technology.

-

Boss Dog leads the Pack with Roland investment

9 Nov 2016

Surrey-based Boss Dog is a well-established vehicle wrapping expert.

-

Boss Dog leads the Pack with Roland investment

9 Nov 2016

Surrey-based Boss Dog is a well-established vehicle wrapping expert.

-

New Mimaki UJF-6042 MkII lands on UK soil

9 Nov 2016

Following its unveiling at VISCOM Paris, the new and upgraded Mimaki UJF-6042 MkII small format UV flatbed printer has landed on UK soil and is now available for demonstration at UK and Irish Mimaki distributor Hybrid Services.

The new A2 Mimaki UJF-6042 MkII offers a number of superior features over its highly successful predecessor, such as increased productivity with print speeds 20% faster than before and exceptional print quality. Hybrid’s National Sales Manager for Industrial Products, Stuart Cole, describes: “We’re delighted to announce the installation of this exciting new product in our showroom in South Cheshire and are really looking forward to providing demonstrations to all interested parties. The UJF series has been hugely popular since its launch in 2009 and now we can see that Mimaki, true to form, has looked at the expanding needs of both the sign and graphics and the manufacturing industries and produced a model that exceeds expectations.”

The UJF-6042 MkII was launched in September along with the smaller UJF-3042 MkII, which replaces the UJF-3042HG, with both the new models printing thicknesses up to 153mm. Their compatibility with a range of Mimaki’s versatile UV inksets, including LUS-120 with flexibility up to 170% to deliver to a plethora of applications and LUS-150 with superior adhesion for outdoor purposes, makes them appealing to several different sectors.

The new MkII printers will sit alongside Mimaki’s other offerings in the UJF series: the affordable entry-level UJF-3042FX that has seen copious installations across the UK and Ireland over the last 7 years; and the UJF-7151plus which gives on-demand printing of the very highest quality at industrial production level.

“We want to provide people with the opportunity to have a holistic overview of Mimaki’s UJF Series and its capabilities all within the comfort of our showroom,” continues Cole. “Installation of the UJF-3042 MkII is expected shortly, meaning we will be able to demonstrate a wide selection of direct-to-object applications with a variety of ink types under one roof, giving print companies the ideal opportunity to get acquainted with this superb range of small format flatbed printers.”

Customers can arrange a demonstration of the new UJF-6042 MkII, or any of Mimaki’s other products, at Hybrid’s showroom by telephoning +44 (0)1270 501900.

Additionally, an extensive selection of Mimaki products is available to view across the UK and Ireland through Hybrid’s specialist reseller network.

Further information can be found by visiting www.hybridservices.co.uk.or www.mimakieurope.com

-

Drytac named in Digital Output’s 22nd Annual Top 50 Readers’ Choice Awards

8 Nov 2016

Drytac has announced its inclusion in USA-based Digital Output’s 22nd Annual Top 50 Readers’ Choice Awards.

-

HP & Alder Hey Children’s Hospital create a healing environment for young patients

7 Nov 2016

When a company with a culture of innovation, a great product designed to better society, and people with the skills and desire to make a difference, all come together, it makes for a great success story.

-

Epson earns Oeko-Tex® Eco Passport Certification for safe & sustainable textile chemicals

7 Nov 2016

Epson’s inks and printers have received the International Oeko-Tex® Association's Eco Passport certification for safe and sustainable textile chemicals. The Oeko-Tex® Eco Passport is an internationally-recognised safety and environmental certification for manufacturers of textile processing chemicals and chemical compounds such as dyes, additives, inks, finishing agents and detergents.

Before awarding the Eco Passport, Oeko-Tex conducts comprehensive tests for harmful substances in textiles and textile accessories based on a large range of criteria and safety standards.

The Oeko-Tex® Eco Passport provides end users and customers with certified assurance that Epson’s inkjet printers and inks have achieved high standards of environmental sustainability and are free of harmful substances. Epson’s certified Eco Passport ink products include the UltraChrome DS ink for the SC-F6000, SC-F6200, SC-F7000, SC-F7100, SC-F7200, and SC-F9200 series' of SureColor dye-sublimation transfer printers, as well as for UltraChrome DG ink and auxiliary fabric preparation products for the SureColor SC-F2000 direct-to-garment printer.

Henning Ohlsson, Epson Corporate Social Responsibility (CSR) Director for Europe, Middle East and Russia (EMEAR), commented: “Epson is delighted to have been awarded an Eco Passport from Oeko-Tex®. Epson continually seeks to contribute to a sustainable society by reducing the environmental impact of its products and services. By achieving Eco Passport certification, we give our customers the confidence and assurance that our textile inks and printers meet the highest possible international safety standards.

“The environment is vitally important for Epson. As part of our drive for sustainability Epson has outlined its Environmental Vision 2050, targeting a 90% reduction in CO2 emissions across the life cycle of all our products and services by 2050. Epson has already taken big strides towards reducing environmental impact across its products and manufacturing processes.”

Epson, which offers a range of inkjet printers equipped with the company's powerful Micro Piezo technology, promotes the digitalization of textile and garment printing. The company's dye-sublimation transfer printers, garment printers, and digital inkjet textile printers enable faithful colour reproduction on textiles, which is difficult to achieve with analogue printing processes. They also render complicated designs down to the finest details while shortening the printing process.

To enable it to provide the same high level of product quality in any country and region in the world, Epson has established unified quality assurance and product safety management policies. Epson's product safety and environmental compliance requirements are explained in the Epson Quality Standard (EQS). This comprehensive set of unified standards is implemented across the Epson Group. EQS specifies independent controls that the company widely implements to meet or exceed legal and regulatory requirements in each country.

-

New EFI Fiery DFEs announced for updated Xerox Colour C60/C70 Printers

6 Nov 2016

Electronics For Imaging today announced the availability of two new EFI Fiery digital front ends (DFE) for the updated Xerox Color C60/C70 Printer.

-

Sign & Digital UK announces launch of new Autumn Product Promotions website

4 Nov 2016

Sign & Digital UK, the country’s leading trade exhibition for the sign making, display solutions and digital printing industry, has announced a new online promotion tool ahead of the 2017 show.

-

Nocturnal ‘Airbus’ takes off with help from HEXIS UK Ltd

2 Nov 2016

Birmingham-based Nocturnal U.K. Ltd. has been in business for more than 15 years and is an expert in vehicle graphics and wrapping, digital printing, point of sale graphics, promotional displays and signs.

The company supplies signs to businesses across the U.K., creating innovative and engaging displays for shops, offices, vehicles and more. One of Nocturnal’s most recent projects involved wrapping a minibus in HEXIS materials to create a stunning ‘Airbus’ minibus for High Society Limousines.

Richard Phillips, Managing Director at Nocturnal, explains: “We have a long-standing relationship with High Society Limousines and have worked on a significant number of vehicle wrapping projects for them over the years. Subsequently, we had a good understanding of what they wanted to achieve with the ‘Airbus’ project.”

The vehicle delivered to Nocturnal for the wrap was not ideal as there were some issues with body work. However, Nocturnal took advantage of the benefits offered by HEXIS products to ensure that the final wrap was as stunning as possible.

Nocturnal used HEXIS HX190WG2 50-μm vinyl for the eye-catching graphics and sealed the images with HEXIS PC30G2 gloss laminate. The HX190WG2 film is perfectly suited to complex surfaces, and adheres particularly well to glass, steel, aluminium, PVC and melamine. Its high technical performance and conformability means that it can be used for full wraps, and on curved and riveted surfaces.

Following its external makeover – and to add to the drama and wow factor of the ‘Airbus’ – High Society Limousines added amplified sound mimicking an aircraft idling, along with running lights for the wings and wheels. Inside, it has had a full fit out including inflight screens, an in-vehicle bar, disco lights and a karaoke machine.

Richard Phillips comments: “The ‘Airbus is proving to be very popular for school proms, hen nights and much more. It makes quite an impact at night when it comes past you on the road, that’s for sure! At first glance it really does look like a plane is running alongside you.”

On working with HEXIS, Richard Phillips adds: “We like their attention to detail and the one-to-one approach and see them as a business partner rather than just a supplier. They are always our first choice for materials - and an excellent source of advice when we need it.”

The biggest challenge on this project was image availability – or lack thereof – for the vehicle wrap. Richard Phillips explains: “We spent a long time researching viable images of the correct size, aspect and appearance and, in fact, the image we used was the only one we could locate that met these criteria. As a result, the company the jet belonged to found out we had used the image and invited High Society Limousines to take part in a photo shoot at Birmingham Airport alongside the actual aircraft.”

Scott Wilkins, Managing Director of HEXIS UK Ltd, concludes: “The ‘Airbus’ project has been a great success. The philosophy and passion within the HEXIS Team means that customer care and customer service – along with our strong customer relationships – are just as important as the high-quality products that we sell. This is evident with our long-lasting relationship with Nocturnal UK Ltd.”

For more information on Nocturnal U.K. Ltd., please visit www.nocturnalonline.co.uk.

For more information on HEXIS U.K. Ltd. please visit www.hexis.co.uk.

-

Roland DG's VersaWorks Dual RIP Software now supports latest Roland inkjet printers

2 Nov 2016

Roland DG Corporation has announced that its recently introduced Roland VersaWorks Dual RIP and print management software now supports several additional Roland DG inkjet printers and printer/cutters.

Roland VersaWorks Dual RIP is currently bundled with the latest generation TrueVIS VG Series and SG Series of printer/cutters, the SOLJET EJ-640 high-production eco-solvent printer and the VersaUV LEF-300 UV-LED inkjet printer. With immediate effect, the following additional models will include the latest Roland VersaWorks Dual when they are shipped:

- SOLJET PRO 4 XR-640

- VersaCAMM VSi Series & SPi Series

- VersaSTUDIO BN-20

- VersaEXPRESS RF-640

- VersaUV LEJ-640, LEJ-640FT, LEC Series & LEF-20

- Texart RT-640VersaWorks Dual builds upon the intuitive, easy-to-use capabilities of VersaWorks to provide high-quality printing while adding enhanced processing and editing functions to ensure faster RIP times and increase even further the efficiency, quality and ease of production. Yuko Maeda, division president of Roland DG business development unit notes that Roland VersaWorks Dual enables users to work not only with PostScript® files, but also allows for native processing of PDF files, which have become popular in commercial printing. This ensures transparency effects are processed accurately and saves time by avoiding the need for additional editing processes such as flattening.

White and clear ink layers can be generated automatically in the RIP, ideal for use in producing transparent window graphics, stickers and personalised accessories with special effects. This functionality simplifies artwork creation and the need for design software in order to create speciality colour artwork. For even greater accuracy, special colour correction adjusts the position and size of special colour data for perfect registration. Features such as offset, positioning, rotation and registration of ink layers can be easily configured in the RIP as well, without the need to return to graphic design software. In addition to saving time, the ability to accurately translate intricate artwork in the RIP also helps print service providers to work more efficiently with their clients as they no longer need to return artwork to the designer for additional editing. Particularly helpful for larger print businesses is the possibility to connect an unlimited number of users to VersaWorks Dual.

In addition to these exciting new features, VersaWorks Dual still offers all of the powerful, useful tools of VersaWorks including smart nesting to minimise media usage and tiling with overlap for positioning accuracy, helpful when printing graphics for large installations. Also, a panel rotate function for consistent colour over long print runs, Variable Data Printing to enable the quick and easy customisation of individual items within a print run, plus Pantone® and Roland Color System Libraries for simplified colour matching, and much more.

“Roland DG understands the important role that software plays in printing,” Maeda said. “We have been developing RIP and print management software for many years. A major benefit for Roland customers is that our software is tailored exclusively for Roland DG printers and printer/cutters, and thus optimised to maximise their performance and ease of use. Our proprietary colour management tools and other functions have become important factors in the popularity of Roland products worldwide.”

“Now that Roland VersaWorks Dual supports native PDF processing,” Maeda continued. “We believe our printers provide an even greater level of value for not only the printing of signs and graphics, but for decorating a wide range of original goods and for prototyping applications such as package printing and press proofs. We are committed to developing powerful, world-class RIP software that makes customers’ work even easier, while expanding their potential.”

As part of Roland DG’s ongoing commitment to supporting its customers, in the near future Roland VersaWorks Dual will be made available to existing users (who already own one of the devices listed above). An easy-to-use online download process will be put in place and Roland DG will be in touch with those customers to confirm when this free-of-charge software upgrade is available.

For more information on VersaWorks Dual, please visit: http://www.rolanddg.co.uk/products/software/versaworks-dual/ or call +44 (0)1275 335540 for a demonstration.

-

Roland DG's VersaWorks Dual RIP Software now supports latest Roland inkjet printers

2 Nov 2016

Roland DG Corporation has announced that its recently introduced Roland VersaWorks Dual RIP and print management software now supports several additional Roland DG inkjet printers and printer/cutters.

Roland VersaWorks Dual RIP is currently bundled with the latest generation TrueVIS VG Series and SG Series of printer/cutters, the SOLJET EJ-640 high-production eco-solvent printer and the VersaUV LEF-300 UV-LED inkjet printer. With immediate effect, the following additional models will include the latest Roland VersaWorks Dual when they are shipped:

- SOLJET PRO 4 XR-640

- VersaCAMM VSi Series & SPi Series

- VersaSTUDIO BN-20

- VersaEXPRESS RF-640

- VersaUV LEJ-640, LEJ-640FT, LEC Series & LEF-20

- Texart RT-640VersaWorks Dual builds upon the intuitive, easy-to-use capabilities of VersaWorks to provide high-quality printing while adding enhanced processing and editing functions to ensure faster RIP times and increase even further the efficiency, quality and ease of production. Yuko Maeda, division president of Roland DG business development unit notes that Roland VersaWorks Dual enables users to work not only with PostScript® files, but also allows for native processing of PDF files, which have become popular in commercial printing. This ensures transparency effects are processed accurately and saves time by avoiding the need for additional editing processes such as flattening.

White and clear ink layers can be generated automatically in the RIP, ideal for use in producing transparent window graphics, stickers and personalised accessories with special effects. This functionality simplifies artwork creation and the need for design software in order to create speciality colour artwork. For even greater accuracy, special colour correction adjusts the position and size of special colour data for perfect registration. Features such as offset, positioning, rotation and registration of ink layers can be easily configured in the RIP as well, without the need to return to graphic design software. In addition to saving time, the ability to accurately translate intricate artwork in the RIP also helps print service providers to work more efficiently with their clients as they no longer need to return artwork to the designer for additional editing. Particularly helpful for larger print businesses is the possibility to connect an unlimited number of users to VersaWorks Dual.

In addition to these exciting new features, VersaWorks Dual still offers all of the powerful, useful tools of VersaWorks including smart nesting to minimise media usage and tiling with overlap for positioning accuracy, helpful when printing graphics for large installations. Also, a panel rotate function for consistent colour over long print runs, Variable Data Printing to enable the quick and easy customisation of individual items within a print run, plus Pantone® and Roland Color System Libraries for simplified colour matching, and much more.

“Roland DG understands the important role that software plays in printing,” Maeda said. “We have been developing RIP and print management software for many years. A major benefit for Roland customers is that our software is tailored exclusively for Roland DG printers and printer/cutters, and thus optimised to maximise their performance and ease of use. Our proprietary colour management tools and other functions have become important factors in the popularity of Roland products worldwide.”

“Now that Roland VersaWorks Dual supports native PDF processing,” Maeda continued. “We believe our printers provide an even greater level of value for not only the printing of signs and graphics, but for decorating a wide range of original goods and for prototyping applications such as package printing and press proofs. We are committed to developing powerful, world-class RIP software that makes customers’ work even easier, while expanding their potential.”

As part of Roland DG’s ongoing commitment to supporting its customers, in the near future Roland VersaWorks Dual will be made available to existing users (who already own one of the devices listed above). An easy-to-use online download process will be put in place and Roland DG will be in touch with those customers to confirm when this free-of-charge software upgrade is available.

For more information on VersaWorks Dual, please visit: http://www.rolanddg.co.uk/products/software/versaworks-dual/ or call +44 (0)1275 335540 for a demonstration.

-

Xerox's Jeff Jacobson to Deliver Keynote Address at EFI Connect 2017

1 Nov 2016

Electronics For Imaging has announced that Jeff Jacobson, president, Xerox Technology, will be a keynote speaker at EFI Connect 2017 - the EFI users' group conference in Las Vegas.

-

New METAZA MPX-95 direct part marking solution for medical instrument traceability announced by Roland DG

28 Oct 2016

Roland DG Corporation has announced the launch of the METAZA MPX-95 DPM barcode impact printing solution, for the affordable track and trace of medical instruments.

The MPX-95 DPM solution permanently marks medical instruments such as scalpels and forceps. With its diamond stylus and powerful impact force, the MPX-95 solution can imprint on a wide variety of materials including stainless steel, titanium, iron, platinum and softer substrates such as gold, silver, brass, copper, nickel and aluminium at high speed and with pinpoint accuracy. Imprinting individual medical instruments with a serial number, 2D symbol or other markings enables management of those instruments, including stock availability, location, usage history and maintenance records.

Yoshihiro Yazawa, Roland DG DPM Manager, Easy Shape Business Development HQ, said: “Regulatory bodies worldwide are seeking a comprehensive management system for instruments used at medical facilities in order to reduce the risk of infection and ensure the safety of patients. In the United States, the FDA Unique Device Identification (UDI) regulation, which requires that all medical devices display a unique identifier, began being phased in from September 2014 and is expected to become compulsory in the EU and Asian countries within the next few years.”

The MPX-95 DPM solution quickly creates 2D DataMatrix barcodes to GS1*1 standards and imprints them on the surface of medical instruments in areas as small as one square millimetre by using dot pin marking to permanently mark surfaces and prevent erasure without the risk of corrosion. A removable base table and plate enables a wide variety of types and sizes of medical instruments to be marked with identifiers. The MPX-95 also comes standard with a laser pointer that assists in identifying the area to be marked so that even healthcare workers without digital technology experience can easily and accurately apply marking with no special training required. The DPM solution consists of software that generates unique identifiers for each instrument, as well as a gripping vice, a sliding vice and clamp pins to hold instruments in place while they are being marked. Both vices allow the position of the item to be fine-tuned by aligning it with the laser pointer after it has been clamped.

For more information, please visit http://www.rolanddg.co.uk/products/engravers/mpx-95_medical/

-

New METAZA MPX-95 direct part marking solution for medical instrument traceability announced by Roland DG

28 Oct 2016

Roland DG Corporation has announced the launch of the METAZA MPX-95 DPM barcode impact printing solution, for the affordable track and trace of medical instruments.

The MPX-95 DPM solution permanently marks medical instruments such as scalpels and forceps. With its diamond stylus and powerful impact force, the MPX-95 solution can imprint on a wide variety of materials including stainless steel, titanium, iron, platinum and softer substrates such as gold, silver, brass, copper, nickel and aluminium at high speed and with pinpoint accuracy. Imprinting individual medical instruments with a serial number, 2D symbol or other markings enables management of those instruments, including stock availability, location, usage history and maintenance records.

Yoshihiro Yazawa, Roland DG DPM Manager, Easy Shape Business Development HQ, said: “Regulatory bodies worldwide are seeking a comprehensive management system for instruments used at medical facilities in order to reduce the risk of infection and ensure the safety of patients. In the United States, the FDA Unique Device Identification (UDI) regulation, which requires that all medical devices display a unique identifier, began being phased in from September 2014 and is expected to become compulsory in the EU and Asian countries within the next few years.”

The MPX-95 DPM solution quickly creates 2D DataMatrix barcodes to GS1*1 standards and imprints them on the surface of medical instruments in areas as small as one square millimetre by using dot pin marking to permanently mark surfaces and prevent erasure without the risk of corrosion. A removable base table and plate enables a wide variety of types and sizes of medical instruments to be marked with identifiers. The MPX-95 also comes standard with a laser pointer that assists in identifying the area to be marked so that even healthcare workers without digital technology experience can easily and accurately apply marking with no special training required. The DPM solution consists of software that generates unique identifiers for each instrument, as well as a gripping vice, a sliding vice and clamp pins to hold instruments in place while they are being marked. Both vices allow the position of the item to be fine-tuned by aligning it with the laser pointer after it has been clamped.

For more information, please visit http://www.rolanddg.co.uk/products/engravers/mpx-95_medical/

-

Modular Zünd G3 helps Bobcat Digital expand at own pace

26 Oct 2016

Bobcat Digital has installed a Zünd G3 L2500 as part of an investment package from CMYUK, which will help it expand and evolve at its own pace.

-

Staffordshire Signs expands vehicle wrapping business with HEXIS UK

18 Oct 2016

Burntwood-based Staffordshire Signs & Graphics is a keen HEXIS product advocate, having worked with the company’s versatile media range for many years.

-

New Mimaki brings breakthrough digital printing to the textile industry

17 Oct 2016

Mimaki has announced the launch of a brand-new textile printer; the Tx300P-1800B (Belt).

-

HP DesignJet celebrates 25 years reinventing design with SPAN Architects

17 Oct 2016

With over 3.3 million HP DesignJet products sold since its first large-format printer in 1991, HP DesignJet celebrates its 25th Anniversary with Matias del Campo.

-

Mimaki to present show-stopping solutions at InPrint Milan

14 Oct 2016

Mimaki will be showcasing its impressive portfolio of innovative solutions for the plastics, sign/graphics, industrial and textile/apparel industries at InPrint Milan. Taking centre stage will be the new UV flatbed UJF-3042 MkII and UJF-6042 MkII printers that deliver best-in-class print speeds with excellent adhesion to acrylics and a wide range of other materials, including glass, metal and resins. These printers are ideally suited to the production of items such as membrane switches or wallet smart-phone cases that require pressing or folding during production.

A variety of ink types are available for these systems, enabling printing on both rigid and flexible materials, including inks designed for durability with excellent scratch resistance, as well as inks that can be stretched up to 170% without cracking. Textures can be added using a unique clear varnish ink.

Adapting to a changing market place

Mimaki acknowledge rapidly changing demands across a broad range of industries as a key driver behind the development of their portfolio, bringing new products to market that help to meet ever more complex and sophisticated production requirements in a flexible, cost-effective and innovative manner.

One of the new trends identified by the company is the demand for improving the aesthetic qualities of ‘functional’ household goods such as washing machines, often resulting in a need for unique print or bespoke control panel on the appliance. Traditional print technologies lack the flexibility to undertake this type of work in a viable and cost effective way. Full colour inkjet technology with a variety of ink types to suit different substrates now makes it possible to print even short runs of items such as intricate control panels and membrane switches in a cost-effective manner, whilst still achieving the required high quality print.

A new take on thermoforming

Mimaki will also be demonstrating its UJF-7151plus multipurpose wide-format printer capable of printing on a variety of substrates including plastics, metal, wood, leather and glass up to 28” wide x 20” long and 6” thick.

The UJF-7151plus will run LUS-350 thermoforming ink – a unique, stretchable ink developed to meet a wide range of thermoforming applications, especially those requiring exceptional hardness and durability, such as automotive parts. Mimaki LUS-350 ink is compatible with the Mimaki UJF-7151plus, JFX200-2513 and JFX200-2531printers. The ink is available in CMYK, white and a unique clear ink that can also be applied to add texture. A Formech 508FS vacuum forming machine on the Mimaki stand will help visitors experience the creative potential of the entire thermoforming process.

Mimaki is distributed exclusively in the UK and Ireland by Hybrid Services Ltd and the company’s National Sales Manager, Industrial Products, Stuart Cole welcomes the latest developments, commenting: “There is no doubt in my mind that the new models from Mimaki are perfectly placed to build on the incredible success of the previous generation UJF 3042 and 6042 machines. The additional development of even more sophisticated inks is set to expand the capability of these machines into areas of production that we could never have imagined a few years ago. The ability to produce an amazing range of bespoke products in an incredibly compact and user-friendly package provides sign and graphics companies, as well as manufacturing and sampling companies with a perfect opportunity to diversify their services with greater flexibility, short-run production and ever more creative applications, which is certain to attract new and more profitable customers.”

InPrint takes place in Milan from 15-17 November 2016 and Mimaki can found on Stand B20.

More details about Mimaki products, including its full range of printers and inks, can be found by visiting www.hybridservices.co.uk

-

Mimaki Europe BV acquires Italy’s La Meccanica Costruzione Tessili-S.P.A

13 Oct 2016

MIMAKI EUROPE B.V. (President and Representative Director Koji Shimizu), a consolidated subsidiary of Mimaki, in accordance with the “Announcement on the Share Transfer Agreement Regarding the Stock Acquisition of Italy’s La Meccanica” disclosed on June 10, 2016, announces that on October 18, 2016 (local time), it acquired all stock shares for Italy’s “La Meccanica Costruzione Tessili-S.P.A.” and converted it to a subsidiary company.

In addition, as of the date the stock acquisition closed, the corporate name of the company has been changed from “La Meccanica Costruzione Tessili-S.P.A.” to “Mimaki La Meccanica S.p.A.” and three of Mimaki’s executives will be appointed as directors. Moving forward, Mimaki will leverage La Meccanica’s product and technological expertise to accelerate its efforts to promote digital on-demand production in the textile apparel market on a global scale.

Future Outlook

“We are pleased to bring La Meccanica’s talented people and advanced technology under the Mimaki umbrella,” said Kazuaki Ikeda, President. “La Meccanica has a great reputation in the textile industry, and this acquisition bolsters Mimaki’s efforts to bring the digital transformation to textile printing. The acquisition of La Meccanica is not expected to have any significant impact on Mimaki’s consolidated performance for the current fiscal term, and thus, there will be no revisions to Mimaki’s earnings forecast as a result of this acquisition.”

-

i-Sub adds EFI VUTEk FabriVU 180 & 340 to soft signage printing range

12 Oct 2016

Specialist distributor and reseller to the textile printing market i-Sub has added the powerful and cost-effective EFI VUTEk FabriVU 180 and 340 high resolution fabric printers to its extensive portfolio.

-

New Mimaki Tx300P-1800B brings breakthrough digital printing to textile industry

12 Oct 2016

Mimaki has announced the launch of a brand-new textile printer: the Tx300P-1800B (Belt). The 1.8 metre wide printer is specifically designed to address the need in the textile and apparel industries for cost-effective, short run printing of textiles for products or samples. Its unique design makes it ideally suited to printing on a wide variety of fabrics, including bulky textured materials, as well as sheer fabric and stretchy materials such as knits. It also eliminates the need for steaming or washing when printing with Mimaki TP400 textile pigment inks, thereby reducing the space required for on-demand textile printing.

Mimaki believes that the significant upturn in online shopping brings with it a growing demand for the creation of custom products, with customers moving their attention away from standard designs widely available in retail outlets. Accordingly, enterprising garment makers are looking for cost-effective solutions that will help them meet the demand for sample production, short runs and bespoke prints. The new Mimaki Tx300P-1800B belt-type printer has been specifically developed to meet these needs, as well as having the flexibility to print to an even wider range of different fabrics than ever before with a comprehensive range of ink set options.

Five ink types increase flexibility

In order to accommodate the wide range of potential applications, Mimaki will be offering five different ink types with the Tx300P-1800B. These include: Sb420 Sublimation Dye Ink designed to work perfectly with polyester-based textiles, either direct to fabric or to a sublimation paper for transfer by heat press, which feature a broad colour gamut including a deep and powerful black; Dd400 Dispersion Dye Ink delivering high light-fastness and outstanding build-up on polyester and micro-polyester for sportswear, curtains, outdoor textiles, home textiles and the auto industry; and TP400 Textile Pigment Ink, probably the most flexible of all the Mimaki textile inks, with its ability to print to a wide variety of textile types such as polyester, cotton, silk, viscose, rayon and wool. This ink also removes the need for steaming or washing, thus reducing time, cost and potential water pollution. However, a binder or primer is recommended to achieve the quality that both manufacturers and consumers demand.

Also available will be Mimaki’s Rc400 Reactive Dye Ink, suitable for printing on natural fibres, such as cotton, silk and wool. It also meets high automotive light-fastness standards but does require pre- / post-treatment of the fabrics to prevent fading and bleeding of colour. The results are sharp images and rich, deep colours. The final ink option is Mimaki's Ac400 Acid Dye Ink which is similar to Reactive Dye Ink in that pre- / post-treatment of the fabric is needed. These inks produce bright, deep colours in the complete gamut of shades required by the fashion and apparel industry as well as good light- and wet-fastness.

Game changing innovation

The new Mimaki Tx300P-1800B will be exclusively distributed in the UK and Ireland by Hybrid Services Ltd and the company’s National Sales Manager - Textile & Apparel, Stephen Woodall comments: “This is a very exciting development for the textile and apparel printing industry, bringing speed, quality and flexibility to the market at a very accessible price.

"The Tx300P-1800B really does bring game-changing technical innovation in textile print within the reach of many more garment makers and manufacturers. The printer's belt media transport system flattens the textile and makes it possible to print easily on textiles that stretch."

Next-generation digital textile printing

The new Mimaki Tx300P-1800B has been developed to deliver all the capabilities of the next generation of textile printers at an attractive price point with a host of new technical innovations. The new machine is capable of printing at up to 50 square metres per hour, and can also achieve print resolutions of up to 1,440dpi. The adjustable high head gap prevents head strikes and enables high quality printing on thick, woven or fabrics with ‘raised’ fibres. The potential for crumpling and bending of fabrics during the print process is further reduced by the belt conveyance system which incorporates a “crumple-free roller” and “paste roller” to ensure beautiful, stable print results. The waveform control function allows each ink to be jetted according to its own specific gravity and viscosity, for precise placement of ink droplets onto the fabric.

Reliable, uninterrupted continuous operation is catered for by the inclusion of a Nozzle Control Unit to automatically detect and recover clogged nozzles with reduced wastage and the machine also uses two-litre ink packs which further support continuous printing, with reduced operating costs.

The new Tx300P-1800B will be demonstrated for the first time at Viscom Italia in Milan from 13th – 15th October and more details about Mimaki products, including its full range of printers and inks can be found at www.hybridservices.co.uk.

Outside of the UK, interested parties should visit www.mimakieurope.com.

-

Shining a light on Northern Print's expanded VUTEk fleet

11 Oct 2016

Merseyside-based Northern Print has expanded its fleet of EFI VUTEk printers with a new HS100Pro from wide format print specialists CMYUK.

-

HEXIS UK boosts sales team with appointment of Ronan Walshe

10 Oct 2016

HEXIS UK, the exclusive UK distributor of HEXIS S.A.’s full range of media, has announced the appointment of Ronan Walshe as Area Sales Manager for the East and South East of England.

-

HP confirms full compatibility for Caldera V11 with Latex 500 series printers

9 Oct 2016

HP has announced that the Caldera V11 RIP suite has passed the variety of print tests needed to achieve certification for use with the HP Latex 500 series of wide-format printers.

-

See the latest technology at Roland DG’s Experience Days

4 Oct 2016

Roland DG will be holding a series of interactive Experience Days, taking place across the country during October and November.

-

See the latest technology at Roland DG’s Experience Days

4 Oct 2016

Roland DG will be holding a series of interactive Experience Days, taking place across the country during October and November.

-

European debut for Mimaki Tx500P-3200DS at Viscom Frankfurt

3 Oct 2016

Mimaki will host the European launch of the recently announced Tx500P-3200DS at Viscom in Frankfurt from 2-4 November, alongside a wide range of innovative printing solutions for the display and advertising markets. This year, Mimaki will be present on two stands in Hall 8: D44 and E51.

Visitors to Mimaki’s stands at the show will have the opportunity to see the new Tx500P-3200DS grand format textile printer on display for the first time in Europe. In addition, the new UV flatbed UJF-3042 MkII and UJF-6042 MkII printers will be available to view. Visitors will also be able to participate in an interactive exhibit that will engage all five senses in a unique printing experience.

Stephen Woodall, National Sales Manager – Textile & Apparel, at Mimaki’s exclusive UK and Irish distributor Hybrid Services remarks: “Mimaki’s new Tx500P-3200DS offers a combined grand format print and fixation solution, making it ideal for companies looking to leverage the growing soft signage and exhibition graphics sectors. We anticipate considerable interest in the new 3.2m printer and are looking forward to presenting it to our customers.”

In addition to the Tx500P-3200DS, Mimaki will also show its new LED UV small format flatbed range which includes models with 30x42cm and 60x42cm beds that offer improved printing quality thanks to completely redesigned table technology. Also at Viscom Frankfurt, Mimaki will present the new UJV55-320 3.2m grand format LED UV inkjet printer and the Tx300P-1800 textile printer running with pigment inks.

Interactive Exhibition Zone ‘GOKAN’

On its second stand, Mimaki will give visitors a unique interactive sensory experience by applying the Japanese concept of ‘GOKAN’ – five senses. They will be able to view a print job from start to finish and the company’s product specialists will be operating the machines exhibited on the stand. Mimaki’s CJV150 inkjet printer will be used for printing and cutting of images for heat transfer application to T-shirts. Additional solvent printers, cutting machines and a UJF-7151 plus UV flatbed machine will also be available to visitors to participate in this unique approach to the trade show experience.

“This interactive concept is designed to demonstrate the ease of use and suitability for day-to-day applications of our products”, explains Uwe Niklas, General Manager Sales at Mimaki Germany. “Being able to experience print production with all five senses will show digital printing in a whole new light.”

UK customers can find full details of the Mimaki product range by visiting www.hybridservices.co.uk; Customers from other regions should visit www.mimakieurope.com.

[Image shows Mimaki Tx500P-3200DS]

-

Blow away the cobwebs with Mimaki’s Autumn Trade-In

1 Oct 2016

This Autumn, Mimaki’s exclusive UK and Irish distributor Hybrid Services is offering an exceptional Trade-In offer giving companies the chance to receive up to £3,500 cashback until the end of October 2016.

Mimaki’s versatile Sign and Graphics range is stacked with high performance features and makes use of the durable and vivid SS21 ink set that includes silver, white, orange and light black. Available on the Autumn Trade-In are the Mimaki JV150-160 and JV300-160 high-speed printers and the CJV150-160 and CJV300-160 integrated printer/cutters, as Hybrid’s national sales manager for Sign & Graphics, John de la Roche reveals; “This is a terrific opportunity for sign makers and print providers with outdated hardware to make use of their assets and trade up to the latest technology with market-leading functionality from Mimaki. Each of the models available on the offer deliver superior print quality and productivity and coupled with a hearty cashback sum of up to £2,500 it’s a great time to think about upgrading.”

The Autumn Trade-In, which is running until Monday 31st October 2016, also includes the Mimaki TS300P-1800 1.8m production dye sublimation printer, as national sales manager for Textile & Apparel, Stephen Woodall explains; “The TS300P is ideal for print companies looking to provide dye sublimation printing for sportswear, exhibition graphics and fast fashion. It delivers outstanding output with neon and light black ink options and now comes with an extended two-year gold warranty, offering real peace of mind. It’s a unique opportunity to trade-in any printer over 500mm wide, be it dye sublimation, solvent or latex, and get a sizeable reward of £3,500 against a proven dye sublimation printer.”

The Autumn Trade-In is available immediately through Hybrid’s network of authorised resellers and further information can be found by visiting www.hybridservices.co.uk/autumn or by telephoning +44 (0)1270 501900.

-

Sign & Digital UK to celebrate 30th anniversary with new website & show focus

27 Sep 2016

Sign & Digital UK, the country’s leading trade show for the sign, display and digital print industry, has announced the focus for its 2017 anniversary event – a celebration of 30 years of applications, ideas and advice.

-

Roland DG to sponsor Software Training Theatre at The Print Show 2016

27 Sep 2016

Roland DG will be sponsoring the Software Training Theatre at The Print Show, 2016 taking place at the NEC, Birmingham on October 11th – 13th.

-

Roland DG to sponsor Software Training Theatre at The Print Show 2016

27 Sep 2016

Roland DG will be sponsoring the Software Training Theatre at The Print Show, 2016 taking place at the NEC, Birmingham on October 11th – 13th.

-

'Blow away the cobwebs' with Mimaki’s Autumn Trade-In

27 Sep 2016

Mimaki’s exclusive UK and Irish distributor, Hybrid Services, is offering a Trade-In offer on its 1.6m JV and CJV printers and printer/cutters as well as the popular TS300P-1800 dye sublimation transfer printer, giving sign and graphics companies the chance to receive cashback of up to £3,500 until the end of October 2016.

Mimaki’s versatile Sign and Graphics range is stacked with high performance features and makes use of the durable and vivid SS21 ink set that includes silver, white, orange and light black. Available on the Autumn Trade-In are the Mimaki JV150-160 and JV300-160 high-speed printers and the CJV150-160 and CJV300-160 integrated printer/cutters.

Hybrid’s national sales manager for Sign & Graphics, John de la Roche, explains: “This is a terrific opportunity for sign makers and print providers with outdated hardware to make use of their assets and trade up to the latest technology with market-leading functionality from Mimaki. Each of the models available on the offer deliver superior print quality and productivity and coupled with a hearty cashback sum of up to £2,500 it’s a great time to think about upgrading.”

The Autumn Trade-In, which is running until Monday 31st October 2016, also includes the Mimaki TS300P-1800 1.8m production dye sublimation printer.

Hybrid's national sales manager for Textile & Apparel, Stephen Woodall, adds: “The TS300P is ideal for print companies looking to provide dye sublimation printing for sportswear, exhibition graphics and fast fashion. It delivers outstanding output with neon and light black ink options and now comes with an extended two-year gold warranty, offering real peace of mind. It’s a unique opportunity to trade-in any printer over 500mm wide, be it dye sublimation, solvent or latex, and get a sizeable reward of £3,500 against a proven dye sublimation printer.”

The Autumn Trade-In is available immediately through Hybrid’s network of authorised resellers. Further information can be found by visiting www.hybridservices.co.uk/autumn or by telephoning +44 (0)1270 501900.

-

Zünd UK to showcase new double-beam D3 L3200 at Advanced Engineering 2016

27 Sep 2016

Zünd Plotting Systems (UK) will return to Advanced Engineering UK on November 2nd and 3rd (stand D43), showcasing its next-generation modular cutting equipment to professionals from a variety of markets.

-

Senfa appoints SST as exclusive Decoprint distributor in India

27 Sep 2016

French textile company Senfa has appointed Sun Sign and Technologies (SST) as sole distributor of its Decoprint range of products in India.

Decoprint, the inkjet division of Senfa, has rapidly developed a presence in Europe and overseas with its high quality printable textiles for large format and super-wide applications. Its flagship product, Pearl, has become the reference for indoor backlit displays in Europe but the Decoprint range also includes fabrics suitable for frontlit and speciality applications printable on all main print platforms (UV-curing, latex, solvent and direct and transfer sublimation).

In 2015 Senfa invested 8 million Euros in a new 5 metre wide coating line vastly increasing production capacity and also catering for a segment of the market in need of wider media.

Sun Signs and Technologies already has a huge footprint in india being the exclusive distributor of Starflex products. “We are a distributor of premium products for Visual Communication”, explains Deepak Gupta, owner and CEO of SST. “With Senfa-Decoprint, we see a brand that has a proven track record in Europe. Pearl is simply the best product for premium backlit graphics in shopping malls, retail units and airports. The large-format digital print market is moving towards textiles for various reasons. Textiles are certainly more environmentally friendly and easier to transport than PVC banners. Some Indian states have already started to ban PVC products in the sign industry.”

“A local partner is absolutely essential for any company moving into the Indian market,” continues Gupta. “Sun Sign and Technologies has a very long experience in the large format digital print industry and we see a dramatic trend towards printing on to textiles. Sun Sign is more than just a distributor. We are a true partner working hand in hand with our suppliers. Sales of textiles for the indoor market are very often project driven and our people are in with corporate customers and advertising agencies suggesting new ideas and at the same time we offer printing companies immediate access to these new products from local stock.”

Colm Garvey, Senfa Area Sales Manager, adds: “The time is right for expanding into new markets and we are delighted to have Sun Sign on board as our sole distributor in India. I recently visited the country and was extremely impressed by the sheer size of the market – I have been told that a new shopping mall opens in India every single week. We manufacture high quality products and we will be well-represented by SST. They are present nationwide which is a huge advantage in a country as vast as India. I also saw a trend towards higher quality images, especially inside airports, shopping malls and hotels. We see no reason why the year on year growth experienced in Europe cannot be reproduced in India when print-houses see the benefits of printing onto textiles – now available up to 5 metres wide – and stocked locally by Sun Sign and Technologies.”

-

HP adds four new 30-inch HP PageWide printers to product portfolio

27 Sep 2016

HP has announced four new 30-inch HP PageWide Web Presses powered by High Definition Nozzle Architecture (HDNA) technology.

-

HP adds new capabilities to PrintOS and extends compatibility

25 Sep 2016

At Graph Expo 2016, HP Inc. announced new HP PrintOS capabilities and extended compatibility to additional digital press models.

-

Stanford Marsh installs five HP PageWide XL printers at UKHO

21 Sep 2016

Stanford Marsh, a leading independent solutions provider for the wide-format and 3D print sectors – and one of only three UK vendors permitted to supply and service HP’s new PageWide XL Series of products – has installed five new HP PageWide XL 8000 printers at the United Kingdom Hydrographic Office’s (UKHO) headquarters in Taunton, Somerset.

In Europe’s largest HP PageWide installation to date, the UKHO’s five HP PageWide XL 8000 printers form an integral part of an end-to-end solution developed by UKHO in partnership with HP and folding system manufacturer MBO. The new solution is being used to transform UKHO’s chart printing operations.

The UKHO produces nautical charts, publications and services for the Royal Navy and merchant shipping to protect lives at sea. In August 2014, the UKHO started its transformation project to move the lithographic printing of its charts across to digital print. The estimated output volume of the new digital printing system is circa 4 million square metres per annum.

The supply of the HP PageWide XL printers used within the project went out for tender to HP’s UK resellers and was won by Stanford Marsh. Paul Kelly, Production Manager at UKHO*, explains: “We made the decision to go with Stanford Marsh as they could supply the printers at a cost-effective price, and – crucially – they were able to meet the Service Level Agreement (SLA) criteria that we outlined.

“The SLAs we put in place are robust and equate to 92% productivity between 6am and 9pm, five days a week. We require on-site support within four hours of an incident being logged, the problem has to be resolved within six hours, and if it isn’t, a new HP PageWide printer needs to be installed into the workflow and operating successfully within twelve hours. Stanford Marsh was able to offer all of this at a competitive price.”

The end-to-end solution went live in August 2015. Since that time, UKHO has transformed the printing of its 3500 unique charts to a fully digital process and is reaping the benefits of faster production speeds, improved efficiency, reduced wastage, lower stockholding requirements, better environmental credentials, and much more.