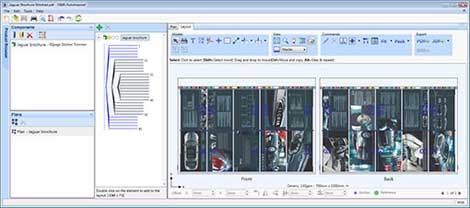

Agfa Graphics has launched Apogee 9, a PDF-based workflow solution that serves as the production hub for graphic reproduction, including commercial printers and wide-format print service providers. With connections to a wide series of output devices and many tools and functions inlcuding integrated nesting and tiling and a new, patented, approach to colour management, Apogee is designed to help commercial printers that are looking to do more for their customers.

“With Apogee 9 as the production hub, commercial printers can automate their workflow, and it helps them to expand into the wide-format inkjet market,” said Andy Grant, Global Head of Software, Agfa Graphics. “Apogee 9 now brings typical wide-format tasks and existing powerful pre-press functions together in one single, PDF-based workflow. It provides them with more flexibility and integration so they can remain competitive with added value products such as banners and posters”

With APPE 3.4, Apogee 9 incorporates Adobe’s latest core technology for processing complex designs, and thanks to HTML5 the new WebApproval portal for page submission and approval can now be used on tablets and other mobile devices. Additionally, Apogee 9 features the third-generation of Agfa Graphics' unique imposition engine with dedicated features for web printers.

Apogee 9, will be on display for the first time at EXPOPRINT LATIN AMERICA 2014 (Sao Paolo, Brasil, 16-22/7) and will be available for customer shipment in Q4 2014.