HARDWARE

SOFTWARE

CONSUMABLES

BUSINESS

CURRENT TRENDING NEWS

- Landa plans expansion with new ink plant in North America

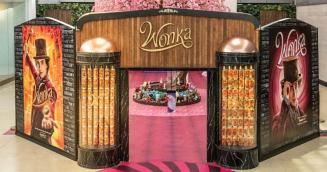

- ReTac Textures film used for Alice in Wonderland wall graphics

- Agfa launches next-gen Hybrid Anapurna H3200 inkjet printer

- printMAX retains title as Roland's most successful UK dealer

- Industry shaping technologies to be unveiled by Ricoh at FESPA

Tags

Zund

-

Zünd UK evolves with new name, new technology and new faces

28 Aug 2017

Following its acquisition by Swiss family business Zünd Systemtechnik AG earlier this year, St Albans-based Zünd Plotting Systems (UK) Ltd has announced an official name change to Zünd UK Ltd. The new, simpler name reflects a continued progression for the company, a leader in digital cutting technology.

New technical innovations will also be on show at Zünd UK Ltd's dedicated demonstration centre following a forthcoming refurbishment. New Zünd machines fitted with over-cutter cameras and laser modules – both of which were unveiled at FESPA this year – will be on display for customers seeking in-depth looks at Zünd technology away from busy trade show floors. Zünd UK is also planning to hold a number of open house events next year, introducing more people to the cutting-edge range.

Furthermore, Zünd UK Ltd has announced the appointment of new sales personnel. James Newnham, Paul Whitford and Steve Rowbotham have all been appointed Sales Account Managers, while Thomas Scott is a new Sales Technician.

As part of the changes at Zünd UK, the email addresses for sales and support teams have also been altered to salesuk@zund.com and supportuk@zund.com respectively. The phone and fax numbers remain the same.

"Becoming a subsidiary of Zünd Systemtechnik AG this year has enabled us to make big changes here at Zünd UK Ltd, including streamlining our name," comments Stuart Cole, Managing Director, Zünd UK Ltd.

"Our demo centre is getting a revamp with our very latest innovations that make digital cutting processes even faster, more automated and more efficient, while our customers will see new faces in our sales team.

"We're looking forward to meeting new and existing Zünd users both at our demonstration centre in St Albans and at forthcoming trade shows – with plenty more events planned for 2018."

Zünd UK Ltd will be exhibiting at Packaging Innovations in London on September 13th and 14th 2017 (Stand D2) and at Advanced Engineering in Birmingham on November 1st and 2nd 2017 (Stand D43).

To book a meeting with Zünd UK Ltd at these shows or at the demonstration centre, or for further information on Zünd cutting systems, please email salesuk@zund.com or call 01727 833003.

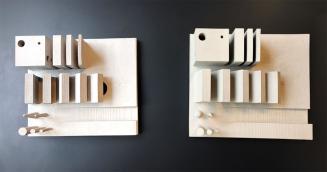

[Picture caption: The renamed Zünd UK Ltd is making changes to its demonstration suite]

-

Zünd UK to present advanced technology for design at Packaging Innovations

24 Jul 2017

Zünd UK will showcase a Zünd S3 M1600 digital cutting system at Packaging Innovations this autumn, demonstrating its exceptional capabilities in sample-making and short-run packaging production.

Returning to the Olympia in London on September 13th and 14th 2017, Packaging Innovations will feature an awards programme, seminars, advice, networking opportunities, new products and machinery demonstrations.

Zünd UK has been a regular exhibitor at Packaging Innovations and can again be found at stand D2 over the two-day event, running demonstrations of the Zünd S3 M1600 and providing information on the entire Zünd range.

In particular, the Zünd UK team will be showcasing the benefits of the Zünd S3 and its complementary software, modules and tools for packaging designers looking to increase the speed, accuracy, cost efficiency and overall quality of their samples and short-run work.

The machine will be processing carton and corrugated materials typically used by businesses in this market, but can handle a wide range of substrates including plywood, plastics and foams – meaning packaging professionals can explore potential diversification channels.

"Packaging Innovations is always a hotbed of ideas and talent so we're looking forward to returning to the show this September," comments Stuart Cole, Managing Director, Zünd Plotting Systems (UK) Ltd.

"There has been a real surge in brilliant packaging design in recent years so we expect to encounter plenty of questions about how Zünd equipment can help make innovative design ideas a tangible reality, especially in terms of small-batch products and personalisation."

Like all Zünd digital cutting systems, the Zünd S3 has a modular design to ensure each user has the perfect configuration to meet their needs – both upon installation and in the future, with upgrades, changes to modules and new tool installations possible at any time. At Packaging Innovations, visitors will be able to see demonstrations of the Zünd S3 M1600, a medium-sized option in the S3 range; cutting tables with smaller and larger bed sizes are available, all with an energy-efficient vacuum system to hold down material for accurate cutting.

Zünd systems are manufactured in Switzerland under strict quality and safety principles, offering highly automated, powerful capabilities for a plethora of businesses.

Packaging Innovations 2017, co-located with Luxury Packaging 2017, will take place at the Olympia in London on September 13th and 14th 2017. To book a meeting with Zünd UK at the show, or for further information on Zünd cutting systems, please email sales@zund.co.uk or call 01727 833003.

[Picture caption: Zünd will exhibit a Zünd S3 M1600 at Packaging Innovations in September]

-

RMC Digital Print chooses reliability and preciseness of Zünd to remove bottleneck

12 Jul 2017

A second Zünd digital cutting table has been installed at RMC Digital Print, after the signage and exhibitions graphics specialist encountered a bottleneck in its workflow.

The Hull business installed a Durst printer in January 2017, doubling its flatbed printing capacity, and immediately found it required additional cutting capabilities to honour contracts and keep the print-room running 24/7. Its finishing department already ran a Zünd G3 3XL1600 and decided to invest in a second Zünd machine, a Zünd G3 XL3200.

"We needed to act fast to deal with the bottleneck created by the new flatbed printer," explains Nicole Spencer, Operations Director at RMC Digital Print. "Zünd provided a really quick turnaround – about six weeks from ordering the G3 to its installation."

In addition to the potential of a faster installation and an easier pre-press workflow offered by choosing a second Zünd, RMC Digital wanted to replicate the reliability and precision demonstrated by its first Zünd machine.

"Our existing Zünd runs day and night so we knew reliability wouldn't be an issue if we bought another Zünd," says Nicole Spencer. "It also cuts very precisely: when cutting hoarding or back walls for interiors, for example, being half a millimetre out can make a big difference."

The Zünd G3 XL3200 can handle Dibond and ACM hoarding quickly thanks to its 1Kw Router module, while RMC Digital Print also upgraded its creasing tool to fold foam board or card material in on itself – a niche job for one of the company's customers.

"Our customers want fast turnarounds and often change deadlines so we have to move work around on our production schedule," says Nicole Spencer. "We have to react quickly to changes in demand so having the second Zünd allows us to pre-press the job just once and we know it will be finished accurately."

RMC Digital Print chose the Zünd G3 XL3200, a narrower but longer model than its first cutting table, which also has a conveyor to feed roll materials. The G3 can be tailored to specific cutting needs easily thanks to its modular construction and material handling options, making it a future-proofed cutting system ideal for a wide range of businesses across numerous industries. Its Swiss design exceeds safety standards and offers the highest automation capabilities, increasing output and minimising human error.

"The combination of Swiss manufacturing and a UK-based engineering team enabled Zünd UK to very quickly respond to RMC Digital Print's requirement for a reliable machine capable of the most accurate work," comments Stuart Cole, Managing Director, Zünd Plotting Systems (UK) Ltd.

"The Zünd G3 is simply designed and built for 24/7, precise operation for demanding customers, so we expect the business to significantly increase its output."

In May 2017, Zünd Plotting Systems (UK) Ltd became a subsidiary of Zünd Systemtechnik AG, a family business based in Switzerland, making the St Albans-based company an integral part of the manufacturer offering a full and complete service to its customers in the UK and Ireland.

For further information on Zünd cutting systems, or to book a visit to Zünd UK's dedicated demonstration suite, please email sales@zund.co.uk or call +44 (0)1727 833003.

Picture caption: RMC Digital Print now runs two Zünd digital cutting systems

-

New Zünd Design Center 3.1 – intuitive, versatile, fully featured

10 Jul 2017

With the Zünd Design Center ZDC Illustrator Plug-in, Zünd takes another huge leap forward. ZDC Vers.3.1 offers even greater convenience, a brand-new category of materials, and added functionality.

-

Delta Rubber finds that the 'only limitations are the humans' working with upgraded Zünd

20 Jun 2017

Delta Rubber has part-exchanged its Zünd S3 M800, bought in late 2015, for a new Zünd G3 L2500 following 18 months of significantly increased output.

-

Zünd acquisition leads to immediate investment in customer service and sales team

1 Jun 2017

Following the acquisition of Zünd Plotting Systems (UK) Ltd by Zünd Systemtechnik AG, the company is further expanding with the recruitment of new sales and engineering experts.

-

Zünd wins Best Digital Cutting Systems prize at EDP Awards

30 May 2017

Zünd is celebrating winning the Best Digital Cutting Systems Award at the EDP Awards, which took place during FESPA 2017 earlier this month.

-

Recruitment: Zünd expansion opens up 3 technical service positions

24 May 2017

Zünd UK is a world leader in the development and manufacture of digital flatbed cutting machinery used in a wide range of industries typically including signs and display graphics, print and packaging, textiles, composites, aerospace, motorsport and the leather industry.

Due to strong growth and continued investment in the development of our customer service provision, Zünd Plotting Systems (UK) Ltd. is currently recruiting for three Service Engineer positions;

- Northern Field Service Engineer

- Southern Field Service Engineer

- Internal Service Support Engineer – Based at St. Albans, UK

For the Field Service Engineer positions, Zünd is seeking a suitably qualified person ideally to HNC, HND, B/Eng or equivalent in any engineering discipline. Candidates must possess strong computer skills and the ability to use CAD or graphics software would be an advantage.

The work involves the installation and maintenance of high value flatbed cutting capital equipment throughout the UK and Ireland and may involve some European travel. Further responsibilities involve training customers on the use of the equipment and software, on site trouble shooting and repair along with remote telephone support.

Candidates must possess good analytical trouble shooting skills, self-motivated, articulate, customer facing, good time management, as well as being able to demonstrate a hands-on, practical and flexible approach.

Candidates should hold a full UK clean driving license and be in a position to travel at short notice if requested - mainly UK and Ireland. The role will potentially involve a proportion of the working week away from home; occasional weekend work may be required.

For the Internal Service Support Engineer position, the primary responsibility will be to provide telephone/remote access support to our customers and site based engineers regarding all our products, services and applications. In house repairs, and in-house machine refurbishments.The candidate must possess a good and articulate telephone manner, customer focus, empathy, good analytical trouble shooting skills, self-motivated, as well as being able to demonstrate a hands-on, practical and flexible approach.

The role could potentially involve a small amount of field based work as and when required. Candidates should hold a full UK clean driving license and be able to travel at short notice if requested.

In all cases the right candidates can expect to receive a highly competitive remuneration package, company car, BUPA, contributory pension and a good team of colleagues. Full product training is provided and we offer opportunities for further development.

Applicants should send their CV with a covering letter to: Louise McCord, Zünd Plotting Systems (UK) Ltd. Unit 1, Spring Valley Business Centre, Porters Wood, St. Albans, Herts, AL3 6PD or by e-mail to louisem@zund.co.uk

-

Zünd UK joins Zünd Systemtechnik AG, with Stuart Cole as MD

23 May 2017

Zünd Plotting Systems (UK) Ltd has become a subsidiary of Zünd Systemtechnik AG, a family business based in Switzerland, following the recent appointment of Stuart Cole as Zünd UK's new Managing Director.

-

Zünd at FESPA 2017: outstanding performance and a coveted award

20 May 2017

Zünd is delighted to record very favorable results from Fespa 2017 in Hamburg, Germany. Before an international audience, the leading manufacturer of digital cutting systems presented, for the first time, its laser module designed for cutting polyester textiles.

-

ScreenServices expands in 50th year with third Zünd S3

3 May 2017

ScreenServices is marking 50 years in the decal and label market – with no plans to slow down: the company has invested in an additional Zünd S3 digital cutting table to increase its productivity and further boost its competitiveness.

-

Bay Cities installs high-performing Zünd D3 cutting system

4 Apr 2017

Bay Cities, a direct designer and manufacturer of packaging and point-of-purchase displays, announced today their installation of the high-speed Zünd D3 Cutter.

-

Zünd's cutting solution brings polymer plate cutting in-house for Reproflex 3

29 Mar 2017

A complete digital cutting solution from Zünd Plotting Systems (UK) Ltd has been installed at Reproflex 3 for the finishing of polymer printing plates, enabling the company to bring the process in-house.

-

Signbox welcomes era of automation with Zünd S3

21 Mar 2017

Signbox is awaiting delivery of its new Zünd S3 L1200, a precision cutting system that will allow the Surrey-based sign business to extend its capabilities.

-

Zund announces plans for FESPA 2017

10 Mar 2017

The Zünd exhibit at Fespa 2017 (Hall B7, Booth D30) in Hamburg, Germany, puts in focus the modularity and the diverse uses of Zünd digital cutting systems.

-

Zünd UK added last-minute to Sign and Digital UK line-up

7 Mar 2017

Zünd Plotting Systems (UK) Ltd will be exhibiting at Sign and Digital UK this month, as a last-minute addition to the line-up.

-

Curtis Packaging installs new Zünd S3 as part of £1.3m expansion

22 Feb 2017

Curtis Packaging has installed a new Zünd S3 M1200 digital cutting table in a purpose-built area of its new 20,000sq ft premises in Redhill.

-

Yes it can: Zünd G3 ticks every box for auto interiors specialist KJ Ryan

2 Feb 2017

KJ Ryan says its recent purchase of a Zünd G3 2XL3200 digital cutting system was 'the obvious choice' that has accelerated its production of prototypes and completed designs for the automotive interiors market.

-

Garthwest upgrades quality of packaging samples with modular Zünd G3

30 Jan 2017

Packaging and POS specialist Garthwest has upgraded its sampling department to include a Zünd G3 L2500, which 'gets it right first time every time'.

-

EFI announces new VUTEk printers at Connect Conference

18 Jan 2017

Customers from around the world are at Wynn Las Vegas as the Electronics For Imaging, Inc. Connect event once again reached sell-out capacity, with attendees from 37 nations gathered to participate in one of the print industry's longest-running and most successful users' conferences. This year's Connect features important technology advancements from EFI, including the debut of the company's largest soft-signage printer and new LED, roll-to-roll printers offering market-leading productivity.

Connect is still growing in its 17th year, with pre-registrations surpassing last year's record customer attendance. The conference, which caters to customers' evolving needs for information related to market and technology trends, features 8 new educational tracks in an agenda of 200+ classes. Special sessions include fireside chat keynotes with Quad/Graphics CEO Joel Quadracci and print technology veteran Jeff Jacobson, speaking on Connect's opening day in one of his first public presentations since becoming CEO of Xerox two weeks ago.

In addition to the new printers, EFI is unveiling version 5 of its Productivity Suite end-to-end workflow offerings at Connect. And, the company is highlighting next-generation EFI Fiery digital front end (DFE) production technologies that deliver uncompromising quality and productivity in digital print production. Many Connect sessions uncover the ways these new products and other EFI offerings drive customer productivity and growth by creating new opportunities and streamlining workflow processes.

In his opening keynote speech at the Conference EFI CEO Guy Gecht addressed artificial intelligence and the impact the next wave of advanced technology is having. Some ERP and MIS workflow products developed by EFI, for example, learn to be more efficient as they track business's operations.

"As with the developments we have all seen with personal computers and mobile technology, artificial intelligence promises to create more opportunities," said Guy Gecht, CEO of EFI in his keynote address. "In print, it can drive preventive diagnostics and predictive maintenance, which helps our customers improve their top and bottom lines."

Worldwide premiere of superwide roll-to-roll and soft signage printers

During Connect, EFI is announcing its new VUTEk 5r and 3r printers, which are designed to be the industry's most technically advanced LED roll-to-roll production offerings. Printing at speeds up to 4,896 square feet per hour in resolutions up to 1,200 dpi, the 5-meter EFI VUTEk 5r and 3-meter EFI VUTEk 3r printers maximise performance, efficiency and quality. Featuring high-resolution, 7-picoliter EFI UltraDrop™ Technology, the new printers offer the fastest throughput in the market, superior image quality and a lower total cost of ownership for premium graphics work. The printers are also available with a complete range of upgrade options for high productivity and versatility, including optional light colours and white for multi-layer printing; inline finishing for all-in-one printing, cutting, slitting, and collecting; auto backlit and blockout printing, and more.

Rami Cohen, general manager of the Rishon LeZion, Israel-based print business Campus Digital Imaging, recently replaced a pair of 2-metre solvent printers and a sublimation printer with the new VUTEk 3r model, a move that has reduced his turnaround times from two or three days to same- or next-day delivery. "It's faster than the three machines it replaces combined," Cohen said of his new printer. "Before, we had to move finished rolls to a dedicated machine to cut them into sheets. Now, the sheeting and slitting happen on the fly, simultaneously with the printing itself."

The new, superwide, roll-to-roll LED printers are available now. The 5-metre VUTEk 5r printer is being shown for the first time in Connect's center for innovation.

Superior, seamless imaging with the VUTEk FabriVU 520 printer

Customers can take advantage of fast-growing soft-signage opportunities using EFI's largest soft signage printer, the 5.2-meter EFI VUTEk FabriVU 520 launched at Connect. The printer gives users new capabilities for producing a broader range of soft signage products, including wall murals, theater drapes, and other superwide seamless applications.

After purchasing a 3.2-metre EFI VUTEk printer last year, marketing communications company Image Options has also just become one of the first companies in the world to install the 5.2-metre FabriVU model. The pair of advanced soft signage production devices has helped the Foothill Ranch, Calif.-based company grow its service offering.

"Image Options invested in EFI's soft signage products with the FabriVU 340 and, because of the demand we have seen, we quickly expanded our capabilities with the new FabriVU 540 printer," said Tim Bennett, Image Options' CEO. "This technology allows us to enter new markets with the widest and highest-speed performance available on the market today. The new 5.2-metre printer also gives us the ability to offer high-quality capabilities to clients who need un-seamed exhibit graphics."

The printer can produce up to 4,800 square feet (446 square metres) per hour, and prints at resolutions up to 2,400 dpi. It can do both direct-to-textile and transfer printing with an easy changeover using the same inkset for greater versatility. A patented ink-recovery system saves more than 95% of the ink lost in textile printing systems offered by other manufacturers.

Both new VUTEk printers on exhibit at Connect feature the latest-version EFI Fiery proServer DFE, which gives users the advantage of fast RIPing, accurate, high-quality colour and robust production management. EFI also is presenting a technology demonstration of a new, 65-inch wide EFI Wide Format LED inkjet hybrid roll/flatbed printer at Connect, showing the continuing evolution of the proven, energy-efficient and versatile 'cool cure' platform that has become the industry's most popular choice for production-speed LED imaging.

Certified, end-to-end workflows, backed by EFI's industry leading expertise

EFI Connect's workflow sessions focus on the advancements of the industry's largest software portfolio with version 5 of EFI's six Productivity Suites - the Commercial Print Suite, the Midmarket Print Suite, the Packaging Suite, the Quick Print Suite, the Publication Print Suite and the Corrugated Packaging Suite. Training, customer panels and voice-of-customer sessions at Connect discuss important capabilities, new solutions for different market segments and the value of the components that make up each Suite.

This year's conference will help print operations drive margins, increase throughput and eliminate errors and downtime with comprehensive training offered in MIS/ERP workflows and in components covering eCommerce, shipping, fulfillment, scheduling, imposition, planning and EFI's new textile software offering. The in-depth technical training in 16 educational tracks includes eight brand new tracks, as well as hands-on sessions, that allow attendees to closely target their specific business challenges.

A consultative approach to customer success

The educational offerings reflect the unmatched level of customer consultation and knowledge-sharing EFI offers at Connect and in direct customer interactions through its Business Consulting Services organisation. Print and packaging businesses worldwide advance their operations with EFI training, analysis and consulting services that give them the competitive edge for more-efficient management using EFI Productivity Suites, MIS/ERP workflows, value-added components and integrated DFEs and printers.

Connect attendee Wayne Peterson, executive vice president and COO of South Burlington, Vt.-based publication print business Lane Press, is using EFI's workflow technology and business consulting offerings to substantially improve efficiency and increase customer satisfaction. The company, which has an EFI Publication Print Suite with EFI Monarch as its core ERP software, is driving improved results to its bottom line by working with EFI consultants and maximising the use of its workflow software. As a result of an EFI Business Consulting Assessment of its workflow, "we have eliminated redundant processes, as well as more than half the forms we used to use," according Peterson. "And we went from 80% to nearly 100% on-time delivery."

Uncompromising digital print quality with the latest EFI Fiery products

Attendees are gaining new insights into their digital production workflows at Connect with the range of new and updated EFI Fiery® DFE products at the conference. The event features the new Fiery NX server and NX Station for fast RIPing and streamlined cut-sheet production automation; Fiery DFE products for wide- and superwide-format inkjet proofing and production; and Fiery Workflow Suite offerings that boost productivity with best-in-class tools for document imposition, assembly, late-stage editing, visual make-ready, prepress automation and more. The newest version of EFI Fiery Navigator™ on display simplifies the process of analyzing daily digital print operations and long-term trends, delivering actionable business intelligence in a customisable, visual dashboard while providing device management capabilities.

Fiery products shown at Connect provide top quality without compromise in digital production printing to the most rigorous production demands. EFI Fiery technology continued its advanced colour leadership by recently becoming one of the first offerings in the industry to successfully handle all 48 test patches in the new Ghent Workgroup PDF Output Suite version 5.0 - a critical test factor and de facto standard for determining quality printing of PDF documents.

Connect also features new technologies and exhibits in its solutions centre from EFI partners, including: 3M, Berger Textiles; Canon; Duplo; Enfocus; Esko; KDX America; Klieverik; Kodak; Konica Minolta Business Solutions U.S.A., Inc.; NextWave; The Print and Graphics Scholarship Foundation; Print ReLeaf; Progress Software Corp.; Ricoh Americas Corp.; Riso; Xerox and Zünd.

EFI Connect is the printing industry's best venue for open dialogue and idea exchange, giving customers a valuable opportunity to participate in educational sessions, receive hands-on experience, discuss industry trends, network with peers, voice their opinions, and learn from others. For more information on the conference or on EFI products, visit www.efi.com.

[Image shows EFI VUTEk 5r printer]

-

Zünd's new RM-L router enhances power, versatility & automation

17 Jan 2017

With the high-powered RM-L router option, Zünd is bringing to market a robust new routing solution.

-

Recruitment - SALES ACCOUNT MANAGER, London/South East England

12 Jan 2017

Zünd UK Ltd are currently looking for a Sales Account Manager to sell our hardware and software solutions to customers, both new and existing, in order to become their preferred supplier. The successful applicant will be focusing on customers based in London and South East England.

-

Zünd UK to demonstrate versatility of S3 at Packaging Innovations

11 Jan 2017

Zünd Plotting Systems (UK) will be exhibiting at Packaging Innovations in Birmingham on March 1st and 2nd 2017, with a Zünd S3 M1600 the main focus of its stand (G29).

The Zünd S3 M1600 digital cutting system will show its versatility and robustness on a variety of carton and corrugated boards, demonstrating why packaging companies around the world have chosen the machine for innovative prototype design and short-run production.

The Zünd S3 range includes a variety of sizes, tools, modules and material handling systems; the model on show at Packaging Innovations 2017 is one of the larger options and is popular with packaging specialists. Zünd plotting tables have a modular construction and, thanks to this, users can invest in a configuration that can both meet their immediate needs and allow them to be future-proofed ahead of changes to their business.

A team from Zünd UK – based in St Albans – will be on hand at stand G29 throughout the event to demonstrate the Zünd S3 M1600 with carton and corrugated boards and to advise on the entire range of Zünd UK equipment, service and support options.

The March 2017 edition of Packaging Innovations will take place at Birmingham's NEC and will incorporate Contract Pack and Ecopack. It follows a London outing for the show in September 2016, at which exhibitor Curtis Packaging purchased the display model demonstrated on the Zünd stand.

"Both Packaging Innovations shows, in Birmingham and London, are a great way to explore the whole of the packaging industry, to meet new and existing customers and listen to their needs," says Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd.

"We'll be demonstrating the Zünd S3 M1600 which is an excellent machine for packaging specialists who use corrugated and carton materials, but also many other businesses in a variety of fields working across dozens of applications. For packaging experts who wish to expand into other areas or simply to accelerate their existing processes, it offers an extremely reliable investment."

For further information on Zünd digital cutting equipment or to book a meeting with Zünd UK at either Packaging Innovations events in 2017, please email sales@zund.co.uk or call 01727 833003.

[Picture caption: A Zünd S3 digital cutter will be on display at Packaging Innovations 2017]

-

Caps Cases has sights on POS & bespoke packaging with Zünd D3 investment

5 Dec 2016

Caps Cases says it plans to expand into new areas including the point-of-sale (POS) and bespoke packaging sectors.

-

Wilmot-Budgen doubles production speeds following Zünd D3 installation

16 Nov 2016

Wilmot-Budgen says it has doubled production speeds on two-sheet cutting processes following the installation of a brand new Zünd D3 XL3200 digital cutting table, combined with its existing Zünd Board Handling System.

-

Modular Zünd G3 helps Bobcat Digital expand at own pace

26 Oct 2016

Bobcat Digital has installed a Zünd G3 L2500 as part of an investment package from CMYUK, which will help it expand and evolve at its own pace.

-

Zünd UK to showcase new double-beam D3 L3200 at Advanced Engineering 2016

27 Sep 2016

Zünd Plotting Systems (UK) will return to Advanced Engineering UK on November 2nd and 3rd (stand D43), showcasing its next-generation modular cutting equipment to professionals from a variety of markets.

-

EDP awards new Zund D3 "Best wide format finishing solution" at drupa

14 Jun 2016

The new Zünd D3 cutter, which made its debut at Drupa 2016, was given the EDP Award 2016 for 'Best wide format finishing solution'.

-

Wilmot-Budgen to upgrade to brand new Zünd D3 following drupa reveal

8 Jun 2016

Following its unveiling at drupa, the brand new Zünd D3 digital cutting table will be installed at point-of-sale (POS) specialist Wilmot-Budgen.

Surrey-based Wilmot-Budgen invested in a Zünd G3 XL3200 with Board Handling System earlier this year, making it the first business in the UK to have the complete system. However, the company was keen to push its production even further and installed the Zünd G3 on the basis that it could be upgraded to the even more productive Zünd D3 following its launch on May 31st.

The company – a specialist supplier of print and POS to major retailers and leading brands – already used an older Zünd G3 XL1600 for the creation of prototypes, but was impressed by the increased automation offered by the newer models and the Board Handling System, so ordered an additional Zünd G3 table for its production department.

"We were the first business in the UK to have the Board Handling System and are really pleased with it," says Peter Burford, Operations Director at Wilmot-Budgen. "It feeds, cuts and delivers material automatically allowing for longer runs to be unattended.

"We had been keeping an eye on Zünd's R&D and when we were told about the new Zünd D3 we made the purchase based on having it installed after its launch."

Originally designed for the leather-cutting market and now re-engineered for display graphics and other applications, the Zünd D3 features two beams to significantly increase productivity while retaining the highest levels of automation, accuracy and safety. Four models are available – Zünd D3 L3200, Zünd D3 XL3200, Zünd D3 2XL3200, Zünd D3 3XL3200 – to cater for many different applications.

Wilmot-Budgen will be swapping out its existing Zünd G3 XL3200 for the new Zünd D3 XL3200, but keeping all of the Board Handling System elements at either end. This is possible thanks to the flexible, modular design of Zünd cutting tables, which allows expertly engineered tools and systems to be changed and replaced as users' needs evolve, retaining the table's performance and value over time.

"The new Zünd D3 is an extraordinarily efficient machine," says Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd. "The dual beam system multiplies production while retaining high levels of automation, meaning even more output for less effort.

"Many of our customers use their Zünd cutting machines on double shifts and even 24/7 operation, so we needed to meet demand for increased automation and productivity. Therefore we were delighted to unveil the new Zünd D3, alongside our colleagues at Zünd Systemtechnik AG, at this year's drupa event. Wilmot-Budgen will be sure to put it, along with the Board Handling System, through its paces."

For further information or to book a visit to Zünd UK's demonstration suite in St Albans, please email sales@zund.co.uk or call +44 (0)1727 833003.

[Picture caption: The Zünd D3 was revealed at drupa.]

-

Zünd D3 Cutter sets a new standard in productivity

6 Jun 2016

With the D3 cutter, Zünd brings to market a new, dual-beam system for high volume, industrial applications.

-

Insight Print Media installs Zünd G3 at new premises in Bristol's creative quarter

31 May 2016

Insight Print Media Limited has expanded into new premises, complete with a new Zünd G3 L2500 digital cutting table and wide-format printing equipment.

-

Zünd UK to unveil whole new level of automation at drupa

27 Apr 2016

A brand new Zünd digital cutting system will be unveiled at drupa, from May 31st to June 10th in Düsseldorf, Germany, offering a whole new level of automation and productivity.

-

Zünd S3 cutter opens up new business opportunities for Nene Packaging

12 Apr 2016

Nene Packaging has installed a Zünd S3 digital cutting table at its Northampton factory, enabling it to produce packaging and display samples for customers of all sizes.

-

i-Sub to host UK debut of four new solutions at SDUK 2016

4 Apr 2016

Print specialist i-Sub will be presenting a range of wide-format print, packaging, textile and finishing technology on Stand F10 at Sign & Digital UK 2016.

-

Zünd G3 cutter creates 'exceptional quality' samples

7 Mar 2016

Irish packaging specialist Cavan Box has invested in a new Zünd G3 L2500 from Zünd UK to produce samples it describes as 'exceptional'.

-

Zünd UK announces availability of Prep Center workflow software

10 Feb 2016

Zünd UK has announced the launch of Prep Center workflow software in the UK, with immediate availability.

-

Zünd to showcase modular cutting solutions at FESPA Digital 2016

22 Jan 2016

Zünd Systemtechnik is pleased to present the latest high-performance, ultra-versatile digital cutting solutions at Fespa Digital 2016.

-

Atlas Packaging praises 'Zünderbar' new Zünd plotting table

13 Jan 2016

Devon-based corrugated packaging specialist Atlas Packaging has installed a new Zünd G3 L2500 digital cutting table from Zünd Plotting Systems (UK) Ltd – describing the machine as a 'Zünderbar' piece of equipment.

Established in 1983, Atlas Packaging is one of the UK's largest independent corrugated companies, providing a complete packaging service to a range of different industries including food and drink, horticulture, automotive, pharmaceutical, furniture and events, and counting businesses such as Waitrose, Asda, and Interflora amongst its customers.

Atlas Packaging converts 30 million sqm of raw material to high-quality finished products every year and previously relied on an older plotting table that it was 'quickly outgrowing', it says. Zünd UK took away the former machine through its extremely successful part-exchange deal, replacing it with a new Zünd G3 L2500. Atlas Packaging also formerly used a Wild Table 10 – a brand supplied by Zünd in the 1980s-90s – which Atlas Packaging says remained reliable for a decade, adding weight to Zünd's reputation for quality and robustness.

"The plotting table is used by our in-house structural design team to create high-quality prototypes which are sent to clients to review, ensuring that the product is perfect before it is approved for full production," explains Dave King, Structural Design Manager at Atlas Packaging.

"We chose to invest in Zünd due to its outstanding reputation for quality, and we were confident that the state-of-the-art Swiss-built machine would enable us to transform our output. The compatibility with our chosen software, Artios and Cape, was also a factor we needed to consider, as this now gives us the ability to render 2D diagrams into 3D prototypes.

"With our new machine and software we hope to push our design skills even further and explore new avenues."

In around 2007, Atlas Packaging's managing director and design manager visited Zünd's St Albans demonstration centre and decided the plotting table on display was an investment for the future. They kept an eye on the Zünd G3 as it was continually improved and upgraded via the numerous videos available online, and opted to purchase the Zünd G3 L2500 though the part-exchange deal when the time was right.

In that period, Zünd's demonstration suite has also been updated as a dedicated, modern space for one-to-one technology showcases, open days and industry events.

The Zünd G3 digital cutting series is designed for maximum automation of cutting and trimming work, with a solid build quality for 24/7 operation. It can handle materials up to 50mm thick and, like all Zünd machines, is offered with an extensive yet straightforward range of modules, tools and material-handling options that can be altered or retrofitted to adapt to each user's needs.

"Our part-exchange scheme proved very popular last year, enabling businesses with old and inefficient plotting tables from other brands to upgrade to a new Zünd at a lower cost," says Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd. "As Atlas Packaging has found, the Zünd G3 L2500 is ideal for sample-making and short-run production purposes, providing accuracy, reliability and efficiency where it is most needed."

Following its installation, Dave King adds: "It is an incredible piece of machinery, propelling us forward with outstanding efficiency – Zünderbar!"

For further information on Zünd digital cutting equipment or to book a visit to its demonstration centre, please email sales@zund.co.uk or call +44 (0)1727 833003.

[Picture caption: The Zünd G3 L2500 was installed at Atlas Packaging at the end of 2015]

-

Zünd UK to showcase continuous production at Packaging Innovations

6 Jan 2016

Zünd Plotting Systems (UK) Ltd will demonstrate its advanced digital cutting equipment at Packaging Innovations 2016 on February 24th and 25th 2016 at Birmingham's NEC.

A regular exhibitor at the specialist packaging event, Zünd UK's stand (H26) will showcase the Zünd S3 M-1600 with tandem vacuum system – a fast, efficient digital cutting table ideal for packaging and print companies requiring continuous production.

Zünd cutters are engineered as modular systems to enable the perfect configuration to be developed for each individual user, and for tool changes to be made at any time following installation. The systems can adapt with the user, allowing for growth and diversification into new applications and materials.

The Zünd S3 model is compact, fast and durable enough to handle materials up to 25mm thick, while being low-maintenance and easy to use. Like all Zünd equipment, it surpasses the highest safety standards for cutting machinery.

At Packaging Innovations 2016, the Zünd UK team will be available to demonstrate the Zünd S3 M-1600 and give information and advice to visitors on how the Zünd range can be an extremely valuable investment for packaging and print-led companies. Based in St Albans and specialising in high-end Swiss-made technology, Zünd UK is known as an expert in the field and supports businesses of all sizes across the country.

"Packaging Innovations is always a highlight of our exhibition calendar as it's an excellent opportunity to talk to members of an exciting industry and discuss how our technology can help bring their ideas to fruition," says Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd. "Packaging is a thriving market with almost unlimited innovation. We're looking forward to the show."

Packaging Innovations 2016 incorporates Contract Pack and Ecopack and is co-located with Empack Birmingham 2016 and Label&Print Birmingham 2016, creating an all-encompassing packaging trade event.

For further information on Zünd digital cutting equipment or to book a meeting with Zünd UK at Packaging Innovations 2016, please email sales@zund.co.uk or call +44 (0)1727 833003.

[Picture caption: The Zünd S3 will be on display at Packaging Innovations 2016]

-

Delta Rubber brings gasket-cutting in house with Zünd technology

2 Dec 2015

Delta Rubber has purchased a Zünd S3 M800 in order to bring gasket manufacturing in-house – a move described as 'a natural development of the business and key to future development'.

Founded in Dorset in 2008, Delta Rubber has steadily expanded into a £1million-turnover company with expansive premises and seven employees. As a specialist in producing parts for industrial sealing purposes, the business has customers in a vast range of industries including marine, automotive, construction, electronics and renewable energy – making parts for products ranging from bird tables to supercars.

"A key part of our success is that we know exactly what we're doing: the whole team has the technical knowledge to understand customers' problems," explains Jon Fisher, Director, Delta Rubber. "A large part of what we do is problem-solving."

Formerly, Delta Rubber was outsourcing most of the production of rubber gaskets, a core part of its product line, to a local company with a digital cutting table. Digital cutting technology is markedly more versatile than traditional gasket cutting presses, as it enables prototypes to be made quickly and easily, whether the client requires one, 50, or more, in a range of sizes. Additionally, the table's tooling can be changed easily to accommodate new materials.

However, Delta Rubber was 'spending significant sums of money' on outsourcing the work, Jon Fisher explains. Bringing the work in-house also increases the speed of turnaround: "These days the pressure of industry means everyone wants their work the same day. We decided to invest in our own equipment to increase that speed of response."

After research carried out by Delta Rubber Director Martin Bailey and a visit to Zünd UK's dedicated demonstration centre in St Albans, the business decided on a reconditioned ex-demo model Zünd S3 M800. It was installed at Delta Rubber in September and 'is going extremely well', says Jon Fisher, adding that it 'its precision is very impressive'. Currently, it is being used for making mould-gaskets for wind turbine blades.

The Zünd S3 cutting table has, like all Zünd solutions, a modular design to allow for changes to its size and function to be made at any time. It can process a wide variety of materials up to 25mm thick, is fast, compact and low-maintenance, and offers superior performance at the highest safety levels.

"The Zünd S3 is an ideal machine for a business like Delta Rubber that caters for such a wide range of customers and industries," says Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd. "It is simple to run, maintain and update and we expect Delta Rubber to see an increase in production speeds too."

Jon Fisher adds: "We started the company in the middle of a recession but have only experienced growth. The Zünd S3 is paying for itself but more importantly, bringing gasket-making in-house is a natural development of the business and key to future development.

"We may well look at other markets in the future and possibly invest in a larger Zünd machine."

Videos showing Delta Rubber's Zünd S3 in action can be found on YouTube: https://www.youtube.com/channel/UC7R1YkMjBDDhukk6XNCStRw

For further information on Zünd digital cutting equipment or to book a visit to Zünd UK's demonstration centre, please email sales@zund.co.uk or call +44 (0)1727 833003.

-

Zünd marks another successful Advanced Engineering UK

23 Nov 2015

Zünd UK is following up a host of prospective orders after a sixth successful appearance at the Composites Engineering Show, part of Advanced Engineering UK.Appealing to designers and manufacturers working with composite materials across a multitude of sectors, the Zünd S3 L1200CVE12 compact digital cutting table on display attracted visitors throughout the two-day event in early November. The Zünd S3 can handle a wide range of materials up to 25mm in thickness easily, quickly and with maximum automation and, thanks to its modular construction, can be built and retrofitted to meet the exact needs of each user.

The cutting system was demonstrated by Zünd UK's team of experts with complementary software: Zünd Cut Centre digital cutting workflow automation, Capturez one-click digitising system for reverse engineering and an automatic nesting system.

"This was our sixth consecutive time exhibiting at Advanced Engineering UK and it continues to be a very worthwhile event for us," comments Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd.

"The event specialises in composites processing in sectors such as aerospace, automotive, defence and architecture so there was a great deal of innovative equipment on display and visitors with exciting ideas. We expect to return next year, but have plenty of business leads to follow up in the meantime."

The Composites Engineering Show took place as part of the annual Advanced Engineering UK event at the NEC in Birmingham on November 4th and 5th 2015. The successful 2015 show follows Zünd's participation in 2014 and 2013, which resulted in direct sales to visitors Gould Engineering and AIM Composites respectively, among others.

To find out more about Zünd digital cutting equipment or to arrange a visit to the Zünd UK demonstration centre in St Albans, please email sales@zund.co.uk or call +44 (0)1727 833003.

Page 2 of 2

- 1

- 2