During the ISA International Sign Expo 2011, from April 28-30 in Las Vegas, NV, booth 3512, EskoArtwork (www.esko.com) will demonstrate a comprehensive portfolio of end-to-end workflow and digital finishing solutions. Highlights at the show include the Kongsberg i-XP 24, the Kongsberg i-XL 24, and the Kongsberg i-XE 10 Auto finishing systems, all with the new i-cut Vision Pro 7.1. Workstations will offer demonstrations of i-cut Suite, a collection of pre-production tools that streamlines the workflow for narrow format and large-format printers alike, from prepress to finished product.

i-cut Vision 7.1 software will be launched at both the EskoArtwork and the i-cut, inc. (#2415) booths during ISA.

Vision control is necessary for digital finishing systems because all printed materials contain size, rotation and scaling distortions that will produce inaccurate digital die cutting, if not corrected. i-cut Vision’s patented means of distortion compensation lets digital cutting systems produce error-free results. i-cut Vision Pro is a fully integrated hardware and software solution that turns a digital cutting table into a true, short-run production system, utilizing a camera system that individually adjusts cut files to perfectly match printed graphics. New to i-cut Vision Pro 7.1 is patent-pending Adaptive Registration, a feature that intelligently reduces the number of registration marks read throughout production, increasing productivity without sacrificing accuracy. Another new, significant feature is the ability to automatically eliminate overcuts in sensitive materials such as foam, Reboard and PSA film, by cutting away from inside corners.

During ISA, i-cut Vision Pro 7.1 systems will be available for purchase at the EskoArtwork and i-cut, inc. booths.

i-cut Suite: Streamlining the entire workflow, from design to print to cut

i-cut Suite was designed specifically for companies that drive narrow or large format digital printers and/or digital finishing systems, and that require professional tools to streamline their workflows. It is the first workflow that offered wide format printing and digital finishing companies a complete, integrated solution. It is comprised of different modules, including i-cut Preflight for efficient PDF preflighting and editing, and i-cut Layout for interactive layout, tiling and nesting of graphics.

i-cut Suite software doesn’t require users to return to a native application, working within a PDF file. Furthermore, it reduces errors by spotting them before RIPping, and it optimises the layout, which ultimately reduces material costs and minimises set-up time. Users with more specific requirements can easily also add supplementary modules: a structural design module to allow integration with all standard structural design programs; a graphics preparation module to create the cutting contour on both vector files and images; and a true shape nesting module offering a powerful, true shape nesting solution, particularly for irregular shapes.

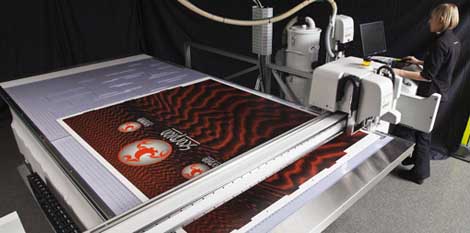

The Kongsberg i-XP 24 digital finishing system offers a completely new level of productivity and throughput

On display at ISA is the Kongsberg i-XP 24, the world’s fastest digital finishing system. The i-XP helps turn short-run POP / POS displays work into profitable, value added jobs, helping sign and display shops offer their customers on-demand production with just-in-time delivery. The Kongsberg i-XP series provides a fast, flexible and highly reliable solution for short run production. With a maximum working area of 87”x126” and a maximum speed of 66” ips (inches per second), the i-XP series can convert a wide range of board, sheet and roll materials. An optional conveyor extension along with an Auto-Feeder with scissor-lift and transfer cart system expands the quantity of print runs that can be pre-stacked. The seamless workflow no longer requires an operator to restack or transfer materials.

Kongsberg i-XE 10 Auto digital finishing system

The Kongsberg i-XE 10 Auto is equipped with a fully automated sheet feeder and off load stacker, specifically designed for finishing small-format, prototype, sample and short-run digital printed materials – rolls or sheets can be processed. The sheet feeder system automatically loads and places the printed materials on the table. The ‘Pick and Place’ automated stacker enables non-stop sorting, neatly stacking finished pieces. The system also automatically separates waste from the finished items. As a result, the machine can run virtually unattended, delivering significant savings on man-hours. The Kongsberg i-XE10 Auto combines high production speed and precision with easy operation. It opens opportunities for creative, new applications with irregular shapes or finishing structures. It can handle a maximum sheet size of 35” x 47” at a maximum speed of 52.5 ips.

Kongsberg i-XL 24: Perfect for signs and displays

The Kongsberg i-XL 24, the workhorse of the product line and best-selling Kongsberg finishing system among sign and display companies, offers a comprehensive finishing solution for the widest range of materials, providing automation, high productivity and outstanding precision. The i-XL family, with a maximum material size of 87” x 120”, can be delivered with an optional conveyor extension, along with the Auto-Feeder and scissor-lift system.

“EskoArtwork continues to extend the productivity of sign and display print providers, with both a complete, integrated workflow and extremely sophisticated digital finishing systems,” explains Bill Hartman, EskoArtwork Vice President, Sign & Display Solutions. " There is much more to the production of signs than just printing. We are committed to “shaping the future” of our customers´ business and this industry. Sign and display shops also need to focus on the structure — or shape — of a sign. They need machines to efficiently cut displays when they are printed. They also need a workflow that can combine graphics with the structure. At the EskoArtwork booth, we can demonstrate solutions that cannot be found elsewhere.”