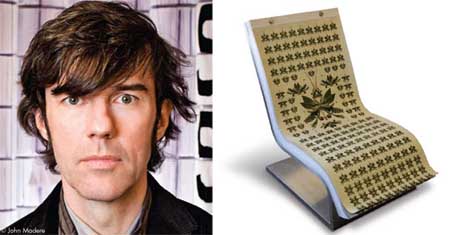

Stefan Sagmeister Turns to HP Graphic Arts Technology to Create the Revolutionary - and Evolutionary - Darwin Chair

Challenge

- World-renowned graphic designer Stefan Sagmeister needed to find a high-quality, durable printing solution that would allow him to realise his vision for the Darwin Chair.

Solution

- The HP Designjet L65500 Printer, HP Latex Ink and HP DuPont™ Tyvek® Banner enabled Sagmeister to create 230 high-quality prints for his design.

Results

- The innovative Darwin Chair is an example of Sagmeister's groundbreaking work and redefines what is possible in the world of furniture design.

Rethinking seating

The work: album covers, posters, books. The clients: Lou Reed, The Rolling Stones, Aerosmith. The reputation: maverick, icon, rock star. The name: Stefan Sagmeister. After more than 30 years in the graphic design industry, Sagmeister has made headlines for numerous reasons, but it all boils down to one thing: groundbreaking graphic design.

With a knack for transforming stale thinking, Austrian-born Sagmeister often pulls inspiration from the ordinary. Take the recent renovation of his studio in New York City. Unable to find furniture he liked and unwilling to settle, Sagmeister decided to design the pieces himself.

"I knew that I needed a few different pieces, including a couple of lounge chairs," Sagmeister says. "I also knew that coming from graphic design, I didn't want to design purely form-based chairs. I wanted to make them quite graphic."

Sagmeister's solution? A chair that can change with you. "The idea developed of designing a chair that has hundreds of sheets of paper as a cushion. Just rip off a sheet of paper, and you have a chair with a new colour, pattern and texture," Sagmeister says.

The evolution of a chair

As his vision of what became known as the Darwin Chair took shape, Sagmeister began to focus on a new question-how to make it happen. "There was just a question of how to make the paper the star and have the structure underneath it recede as much as possible," he explains.

Sagmeister began by examining the structure that the paper cushion was attached to. "Initially, the base was made out of wood, but we changed it to stainless steel. This allowed it to become skinnier and free swinging, so it really became all about the paper."

And just what was it about the paper that deserved the spotlight? "Each of the 230 sheets is printed with a different design," Sagmeister says. The intricate patterns represent the creation of the universe and the creation of the world, from the beginning of plant, animal and human life all the way to the digital revolution.

"Because we wanted the design to have intricate patterns, we needed a high-quality printing technique that could depict very fine lines and many colours. We also wanted something that would reduce the environmental impact of printing. With those parameters, the HP Designjet L65500 Printer was chosen."

The design is in the details

To complete the production of the Darwin Chair, Sagmeister needed to select the paper that would make up the cushion-one of the largest elements of the piece. Having already found a way to offer hundreds of different styles in one piece of furniture, Sagmeister used his choice of paper to extend the life of the chair even further.

"The chair is a piece that will probably have a shelf life of 30, 40 or even 50 years, so we were very careful when we designed these sheets," he notes, acknowledging that the prints could even be given a second life by becoming framed pieces of art. To achieve this level of durability and versatility, Sagmeister decided to print on HP DuPont™ Tyvek® Banner.

Along with rethinking the way the prints could be used, Sagmeister rethought the way they were produced. He reduced the environmental impact of the Darwin Chair's prints by working with the HP Designjet L65500. "It used to be that if you used a printing technique that was more environmentally aware, you always lost something else, like print quality or durability. Now, you're able to have it all," he says.

Design remix

With the creation of the Darwin Chair, Sagmeister went well beyond simply creating new furniture for his studio. His remix of the traditional chair redefines what is possible in the world of furniture design.

And it exemplifies the benefits that anyone can achieve when they push boundaries and rethink the ordinary. Just as Sagmeister was able to break design barriers, commercial printers can also break business barriers and capture new opportunities.

"A lot of things that I do, printers tell me are not possible at first. I like to constantly push the edge there," Sagmeister says. The Darwin Chair is a testament to Sagmeister's ability to rethink the ordinary and to the groundbreaking results.

You can also find more information on the above project by watching this YouTube Video