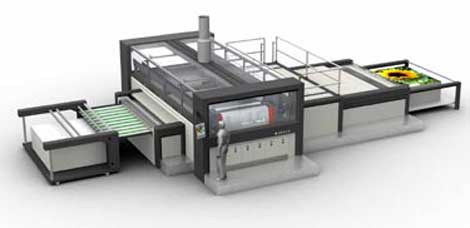

Grapo Technologies, a manufacturer of large format UV roll-to-roll and flatbed printers based in the Czech Republic, is announcing that it will be exhibiting at FESPA, taking place in Munich from 22-26 June 2010. At the show, hall B2 stand 460 the company will be featuring its fully automated Shark hybrid UV printer with feeder/cutter options.

“FESPA is the perfect venue for us to show the latest additions to the Shark,” said Sales Director Branislav Oravec, “including an automatic feeder for rigid materials and cutting system for flexibles. After working with Shark in our own printshop, we believe these options makes Shark even more efficient and productive. At Grapo Technologies we are, first and foremost, printing professionals that manufacture printers designed to meet the specific needs of other printing professionals—we began as a print shop, and always keep in mind the basic requirements of the average print shop owner: a productive, durable piece of hardware capable of generating profit for the business. The feeder/cutter system is a logical outcome of that philosophy as it allows the user to take advantage of the Shark’s speed without requiring two employees to man the machine at all times. ”

New at the show: Shark now equipped with Feeder & Cutter.

The four-color Shark is a multifunctional system capable of printing on both flexible and rigid materials, producing high-quality greyscale images for a wide variety of display applications. Grapo Technologies will be demonstrating the Shark hybrid UV printer at FESPA with a new cutter capable of cutting materials up to 1 mm in thickness transversally or longitudinally, as well as a feeder that can accommodate cardboard sheets and common rigid materials up to a maximum media thickness 10 mm and a maximum size 2000 x 2000 mm, depending on the weight of the material.

Branislav Oravec comments: "In addition to the feeder and cutter, we’ve added more functionality to Shark to improve work flow and productivity. Each model now comes equipped a take up and special guiding system to secure printing of unstable materials such as cardboard, providing users high printing speeds up to 120 m2/hour as well as enormous versatility in applications."

The system can print on either flexible or rigid materials at resolutions up to 960dpi, and can image a maximum print width of 2010 mm with an unlimited print length. Production speed varies from 40 m2/hour for top-quality POS applications to 120 m2/hour for outdoor displays.

“The capabilities of the Shark are normally only found in very high-end printing systems,” commented Oravec. “For example, when working with rigid substrates, manual feeding can often result in expensive errors. The Shark can automatically feed and print 100 sheets per hour, with precise registration, guiding the cut to size sheets to the printer using a unique pause free loading system without compromising on production speed. Because the feeder is automatically driven by Shark software, customers can print up to 100 square meters per hour without human intervention for most substrates. This is truly unique in a printer that comes to the market at the Shark’s low price point, and the market has responded quite favourably. We are excited to share these capabilities with visitors to our stand at FESPA.”

Unique Substrates

“To further demonstrate Shark’s flexibility,” added Oravec, “we will be printing on a wide range of substrates in our stand. This includes textiles, foam, PVC, Forex, glass, polycarbonates, DiBond coated aluminium, acrylic, APET Veralite 100, fluted polypropylene, PVC vinyl, Blueback Paper, Vivak, metal, wood, ceramic tiles, cardboard, and more. This will clearly demonstrate the unique business opportunities this printer can open up for our customers as they work to differentiate their businesses.”