Papergraphics, the wide-format print specialist, and Israel-based 3D printing specialist Massivit 3D Printing Technology have announced a partnership that will bring a revolutionary, super large-scale 3D printing solution to the UK and Ireland markets in May.

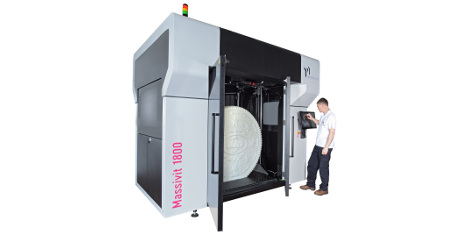

The UK-based company becomes the sole distributor of the Massivit 1800 large format 3D printer and Dimengel 3D printing material. Papergraphics will provide customers with a full service offering, including pre and after sales support. Created to meet the needs of the evolving visual communication market, the system is expected to open up realms of new possibilities to the high end signage market, entertainment industry and events sector.

Having acquired CWE Solutions in January, Papergraphics has been increasing its foothold in the hardware market following 30-plus years producing and distributing high quality media. Today’s agreement with Massivit adds a new dimension to the business, enabling its customers to create bespoke 3D sculptures that are up to 1.8m high, 1.5m wide and have a depth of 1.2m.

The announcement comes immediately after Massivit received an undisclosed investment from Stratasys, the 3D printing and additive manufacturing solutions company - the proceeds of which will be used to further develop, promote and deploy the company’s 3D printing solutions.

Avner Israeli, CEO of Massivit 3D, commented: “Our aim is to build a global presence in the large-format 3D printing market. To do that we are creating a network of experienced partners across the globe. We feel that Papergraphics, with its experience and customer-base in the UK and Ireland, will help us achieve this goal. Not only that, the company is clearly extremely passionate and enthusiastic about the 3D revolution, which will undoubtedly help us achieve our ultimate goal.”

John Selby, CEO of Papergraphics, added: “We are delighted to have signed this agreement with Massivit. We’ve been in discussions with the company about its super-sized 3D printer since September 2015 and our engineers and technical teams have been in Israel learning everything there is to know about the device and the printing material.

“I truly believe that the Massivit 1800 will be as big an innovation for the print industry as the wide format inkjet was when it was launched. This product will change the way the visual communication market operates and the ability to create super large-scale sculptures in just a few hours shifts the goal posts of what is achievable. It’s an exciting time and we’re proud to be the only UK-based supplier of this remarkable technology.”

Papergraphics is expected to begin demonstrations of the product at its Crawley-based headquarters in May 2016.