HARDWARE

SOFTWARE

CONSUMABLES

BUSINESS

CURRENT TRENDING NEWS

- Landa plans expansion with new ink plant in North America

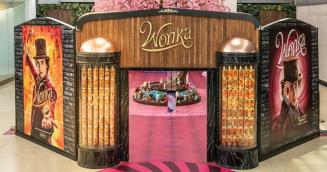

- ReTac Textures film used for Alice in Wonderland wall graphics

- Agfa launches next-gen Hybrid Anapurna H3200 inkjet printer

- printMAX retains title as Roland's most successful UK dealer

- Industry shaping technologies to be unveiled by Ricoh at FESPA

Tags

Installation News

-

LexJet adds 3 new Fine Art Papers to Sunset Line

16 Sep 2019

16 Sep 2019LexJet has long-been known in the printing and graphics industry as the experts in the photography and fine art space, and now continues its leading role by expanding its line of fine art papers, based on the changing market and demands.

-

CHILI hires Fabian Prudhomme as Global VP Sales & Alliances

12 Sep 2019

12 Sep 2019CHILI publish, creator of market-leading software for smart artwork and marketing material creation, is excited to welcome Fabian Prudhomme to the team.

-

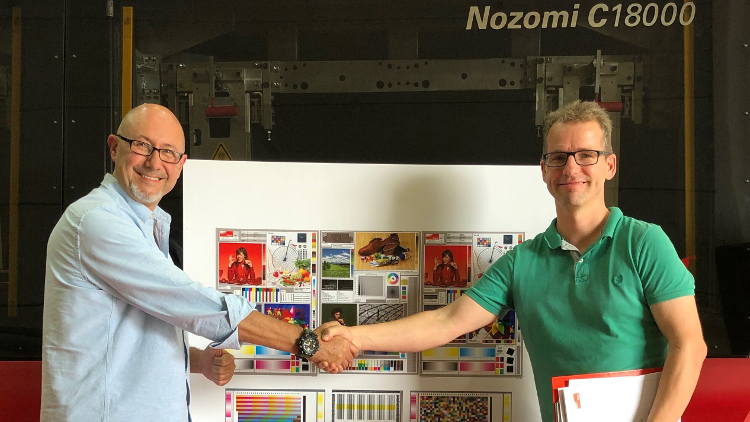

Nozomi C18000 1st corrugated printer to achieve Fogra Certification

12 Sep 2019

12 Sep 2019Dr Andreas Kraushaar, head of the Fogra Research Institute for Media Technologies prepress department, certified the EFI Nozomi C18000 single-pass corrugated printer from Electronics For Imaging, Inc. as Fogra compliant.

-

Grant Fitz hired as EFI's new Chief Financial Officer

11 Sep 2019

11 Sep 2019Electronics For Imaging, Inc. has named veteran tech finance executive Grant Fitz as its new chief financial officer.

-

Hybrid launches new Mimaki SWJ-320EA at The Print Show

11 Sep 2019

11 Sep 2019Mimaki’s UK and Irish distributor, Hybrid Services is set to reveal the brand new Mimaki SWJ-320EA super-wide eco-solvent printer for its European debut at The Print Show, following the machine’s global launch at FESPA Africa 2019.

-

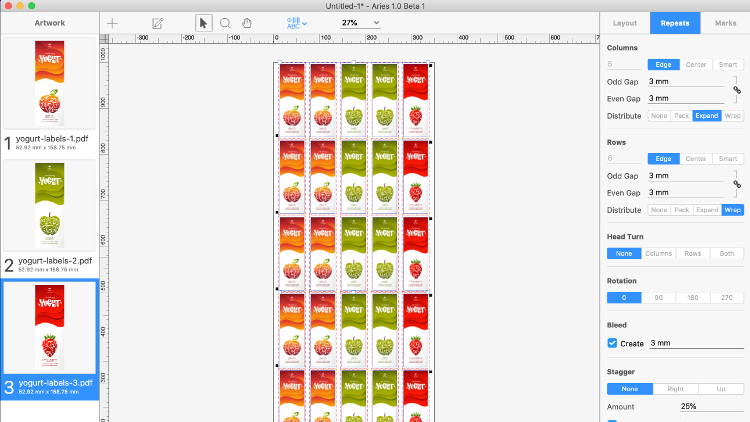

Tilia Labs to launch new software solution at Labelexpo

10 Sep 2019

10 Sep 2019Tilia Labs, Inc., a leading developer of planning, imposition, and Artificially Intelligent automation software solutions for the graphic arts industries, will launch a new solution at Labelexpo that offers to dramatically reduce time and costs in label production.

-

Drytac picks up five SGIA 2019 Product of the Year awards

3 Sep 2019

3 Sep 2019Drytac has been recognized for its adhesive material innovations in an incredible five categories at the SGIA 2019 Product of the Year competition - exceeding last year's win of two awards.

-

Neschen Coating Print'n'Walk film provides perfect adhesion

29 Aug 2019

29 Aug 2019Wherever UV print'n'walk power-tack is applied to, the floor graphics film provides perfect adhesion. The new product from Neschen Coating is a true all-rounder when it comes to application to difficult surfaces: From concrete, wood or carpet to pavement or other surfaces – this high-tack film is a top choice.

-

New 3M Colour Wrap Film Series set to WOW vehicle wrappers

27 Aug 2019

27 Aug 2019Now available from William Smith, the newly launched 3M Colour Wrap Film Series 2080 is set to wow vehicle wrappers with its high conformability, smooth application and added protection during installation.

-

Say 'Yes' to incredible textiles at The Print Show with HP

22 Aug 2019

22 Aug 2019HP will be at The Print Show this year with the first UK showing of the new HP Stitch S series – a portfolio of digital textile printers that deliver incredibly fast and precise colour-matching abilities.

-

PRINTING United Trade Show is sold out

15 Aug 2019

15 Aug 2019The Specialty Graphic Imaging Association (SGIA) today announces that the show floor of its inaugural PRINTING United trade show is sold out.

-

Epson to showcase a range of new products at The Print Show

6 Aug 2019

6 Aug 2019Epson will use The Print Show 2019 (NEC, Birmingham, 17th-19th September 2019) to reaffirm its commitment to the UK signage, textile, label, technical, photographic and dye-sublimation printing sectors.

-

DYSS cutter leaves Tailor Made looking sharper than ever

5 Aug 2019

5 Aug 2019Like many family owned businesses, Tailor Made Signs & Embroidery was set-up as a home based business that has flourished over its 20 years of existence.

-

Color Concepts is adding resources in South Africa

31 Jul 2019

31 Jul 2019Andre Venter has joined our team! He will be the project lead for ColorBase developments and will assist the professional services group with his extensive experience in services like: color management and workflow training, as well as general production optimization consulting.

-

Esko Control Wizard software scoops Intertech Technology Award

29 Jul 2019

29 Jul 2019Following Flexographic Technical Association (FTA) and European Flexographic Industry Association (EFIA) technical innovation awards, Esko Print Control Wizard has again received recognition scooping a 2019 InterTech Technology Award from Printing Industries of America.

-

swissQprint announce live demonstrations at Fachpack 2019

29 Jul 2019

29 Jul 2019UV inkjet printers deliver high-quality prototypes, samples and short runs for packaging and displays. swissQprint, the Swiss manufacturer of large format printers, will showcase these products at Fachpack 2019: Nuremberg Exhibition Centre, Hall 8, Stand 520.

-

WOO partners with OAAA & Geopath at NY Digital Signage Week

29 Jul 2019

29 Jul 2019The World Out of Home Organization (formerly FEPE International) will be hosting a networking presentation with partners the Out of Home Advertising Association of America (OAAA) and research body Geopath in NYC in an opening session for New York Digital Signage Week on October 14.

-

The 29th successful edition of FuturePrint comes to an end

26 Jul 2019

26 Jul 2019The 29th edition of FuturePrint comes to an end with numbers and results far exceeding expectations. The fair, which was held from July 10 to 13, at Expo Center Norte, in São Paulo (SP), received more than 40,000 visitors who wanted to learn about technological innovations, trends and acquire knowledge on the screen printing, sign and textile printing sectors.

-

Avery Dennison joins Ellen MacArthur CE 100

25 Jul 2019

25 Jul 2019Global labeling and packaging materials manufacturer Avery Dennison Corporation (NYSE:AVY) has joined the Ellen MacArthur Foundation’s Circular Economy 100 (CE 100) network as part of the company’s support of a global transition to a circular economy.

-

FASTSIGNS Leeds teams with SIMTrack to brand training facility

25 Jul 2019

25 Jul 2019The Leeds centre of global signage specialist, FASTSIGNS, has teamed up with SIMTrack Driver Performance Centre, to help launch a state of the art driver training simulator facility in the North of England.

-

Spandex introduces ImagePerfect 2926 Easy Glass window film

25 Jul 2019

25 Jul 2019Spandex, the one-stop supplier of innovative solutions to the sign, graphics and display industries, is launching the latest addition to the established ImagePerfect range of specialist window and glass films.

-

Esko to showcase 'Labels Connected' solutions at Labelexpo

24 Jul 2019

24 Jul 2019Leading global provider of integrated hardware and software solutions for label professionals, Esko will showcase its portfolio of innovative products at this year’s Labelexpo Europe.

-

Completion of EFI acquisition by affiliate of Siris Capital Group

24 Jul 2019

24 Jul 2019Electronics For Imaging, Inc. ("EFI" or the "Company"), today announced the completion of its previously announced acquisition by an affiliate of Siris for approximately $1.7 billion.

-

Epson announces low-maintenance SureColor SC-F6300 printer

24 Jul 2019

24 Jul 2019Building on the success of its predecessor, the SureColor SC-F6200, Epson has announced the new SC-F6300, 44-inch, dye-sublimation printer.

-

Kiian Digital boosts its digital textile inks range

14 Jun 2019

14 Jun 2019Kiian Digital is continuing its Textile Printing range’s extension. The core element is the enlargement of the Bellagio line by adding 2 new versions; classifying Kiian Digital's Textile Printing offer at the top on the market.

-

Push Solutions doubles up on powerful innovations from Fujifilm

29 May 2019

29 May 2019Push Solutions, a New Berlin, Wisconsin-based print service provider doubles its wide format LED-UV printing power with Fujifilm’s Acuity F and Acuity LED 1600 II presses.

-

The Vinyl Guys transform hobby into profitable business, thanks to Roland DG technology

30 Aug 2017

Ever wanted to turn a sideline into your main, profit-driving day job? The Vinyl Guys did just that, putting their faith in Roland DG print & cut technology to launch their business into high quality, high reliability production that never fails to impress their customers.

The Vinyl Guys started their route to business success with just a PC and a small 60cm plotter cutter to produce graphics for friends as and when required. Anything larger than the size of the plotter, or that required print, had to be outsourced on demand.

Alex Liggett, Owner of The Vinyl Guys, explains: “I started The Vinyl Guys business as a hobby three years ago, to meet the growing needs of friends in the motorsports sector. Initially, I outsourced all my printing whilst doing as much as I could with the plotter and cut vinyl at home.”

The West Midlands-based company opted to purchase the TrueVIS SG-540 print & cut machine in 2016 after falling in love with the latest of Roland DG’s eco-solvent printers at The Print Show earlier in the year. They purchased their first in-house machine from Grafityp, opting for the SG-540 as a fantastic way to save time and increase profits.

Alex says: “The printer has been pivotal in transforming my sideline enterprise into a profitable business. The difference now is unbelievable. I can print samples, test my artwork and turn work around faster, at a higher quality and at a lower cost. As soon as we installed our Roland, our profit margins grew by a significant amount overnight. Customers also noticed the difference in terms of quality, which meant I could be more creative and offer additional print services.”

In addition to increasing the quality of output and consistency of print, the SG Series printer also enabled Alex to expand what he could offer his customers, meeting tight deadlines, offering exciting custom work and even expanding the types of product he can offer beyond the high-quality vinyl and vehicle wraps which the company is known for. After seeing how successful bringing their business in-house can be, The Vinyl Guys also purchased a laminating system, allowing every stage of the vehicle wrap process to be completed in-house to their high standards.

Alex continues: “As my customer-base grew, outsourcing printing proved to be time-consuming, expensive, and I had no control over the quality of the end-product. It became clear that I needed to invest in a printer and bring all the work in-house. I have used [the SG-540] for banners and posters, but as our main areas of business are vehicle graphics and signage, 90% of the time we are printing vinyl of some sort.”

With a new, exciting job always on the horizon, and every successful application posted across The Vinyl Guy’s social media channels for all to see, it’s easy to see how much the addition of an in-house printer has benefited Alex’s business; and will continue to increase profits and impress customers for years to come.

For more information on The Vinyl Guys, please visit: @TheVinylGuysUK

[Picture caption: The Vinyl Guys use their Roland DG TrueVIS SG-540 printer/cutter to create stunning vehicle wraps]

-

Fresh Graphics expands business offering with Roland DG

17 Aug 2017

Steve Laing, founder of Fresh Graphics, explains why he believes Roland DG is the supercar equivalent of the print industry and the key to commercial success.

-

Hollywood Monster growth continues as UK’s first EFI VUTEk 5r is installed by CMYUK

14 Mar 2017

Unless you’ve spent the last few years intentionally ignoring who is doing what in the wide-format digital print market, you’ll already be fully aware that Hollywood Monster is a pretty big deal when it comes to the volume production of retail sign and display print.

There’s a well-known saying by Aesop – he of Fable fame – that states 'A man is known by the company he keeps'. If we accept that quote as accurate then we have to conclude that Hollywood Monster are currently right up at the top of the wide-format retail print hierarchy, as they’ve have been hanging out with some very illustrious company of late: at a recent thought leadership event, organised by Hollywood Monster and hosted at its Birmingham headquarters, speakers included Andy Street, Managing Director of John Lewis; Gareth Hudson, Head of Development at McDonald’s; Myf Ryan, the Chief Marketing Officer for Westfield; and Social Chain CEO, Steven Bartlett – assembled to investigate and discuss the challenges and opportunities facing the £339bn retail sector.

In fact there’s rarely a month goes by without some news from Hollywood Monster, be that a big retail contract win, a new printer installation, or even news of expansion into new territories around the UK – they recently opened up a new operation in London.

So what’s new at Hollywood Monster right now? Well how about the installation of the UK’s first 5-metre wide EFI VUTEk 5r printer just a matter of days ago.

Supplied and installed by EFI distributor CMYUK, the West Midlands-based display specialist selected the 5m-wide machine for its ability to meet the productivity levels required from its rapidly expanding retail customer base.

Featuring high-quality output with 7 picolitre greyscale imaging in resolutions up to 1,200 dpi, the new VUTEk 5r model offers the fastest throughput in its class, giving Hollywood Monster the ability to maximise quality, performance and efficiency.

Other standout features of the EFI VUTEk 5r printer include: powerful LED-curing technology; unique feature sets such as easy and accurate double-sided backlit and blackout printing; carriage height adjustment and wrinkle analyser to avoid head strikes; handling of rolls up to 750kg; and a raft of other well thought-out operator-friendly features that make the 5r intuitive to use.

In terms of the production speeds achievable, Robin East, Group Director of CMYUK, comments: “We’ve run some initial tests on the new EFI VUTEk 5r, and we’ve already established that we can print saleable quality mesh at 455m²/h , and PVC banner at 212 m²/h. Pretty much any other material we throw at it can be printed in perfect quality at 148 m²/h.”

Just as importantly in terms of overall productivity, the 5r features an inline XY finishing system for cutting and slitting, which enables the production of trimmed-to-size print straight from the printer. Hollywood Monster is now maximising its production time, with a fast print system and less downtime between jobs thanks to this integrated cutting function.

Simon McKenzie, Managing Director at Hollywood Monster, explains: “Prior to the EFI VUTEk 5r installation, we would typically move printed output over to a cutting table for finishing. However, the 5r model’s XY cutting eliminates that process, removing significant delays.

“It’s not unusual for us to print off hundreds or even thousands of banners for big events. Previously they would all have needed trimming on our cutting table, or – dependent on size – even by hand. That entire process is now completed on-the-fly during the print process. It’s a huge productivity boost.

“Being a long-time UV-LED printer user, we already expect increased reliability, instant on/off of the curing lamps, the ability to print sensitive and thin materials, reduced costs of replacement lamps and reduced energy consumption. However, the EFI VUTEK 5r goes beyond that and delivers a number of new features aimed at running cost and waste reduction, including higher ink efficiency and a reduction in media wastage (just 40cm of wasted material per load).”

McKenzie elaborates: “With multiple roll changes daily, combined with the volumes that we print, the reduction in media waste will result in us saving many thousands of square metres annually – over its lifetime, the media savings alone will make a significant contribution towards the machine's purchase cost.

“All told, the EFI VUTEk 5r is a printer that appears to have been designed in association with experienced operators, as almost every new feature seems to solve a problem, improve a process or make the day-to-day running of the system easier and more efficient. For a busy business like Hollywood Monster, that can only be a good thing.”

Robin East concurs: “The VUTEk 5r stands out in its field. EFI is now embedding technology within its printers that dramatically increases overall productivity. Aside of delivering the best in class quality at speed, with inline XY finishing, exceptional media handling and ease of operation, there is simply nothing else out there currently that can compete with this incredible printer.

“This is the sixth VUTEk printer we have installed for Hollywood Monster in the last 12 years. We continue to work closely with the company, and keep them informed of any interesting technical developments. It’s exciting to work with a business as dynamic as Hollywood Monster; a business that embraces technology and innovation to solve problems, increase productivity and continually drive its own success.”

-

Durst Rho P10 inkjet printer delivers best quality production to RMC Digital Print

12 Mar 2017

Investment in a new Durst system to ramp up capacity and further improve quality is at the heart of a £1million expansion programme for RMC Digital Print in Hull.

Durst, the manufacturer of advanced digital production technologies, has installed the new Rho P10 inkjet system that gives RMC the opportunity to print on the widest range of rigid and roll media through unrivalled versatility. The six-colour configuration including a white option also enables RMC to continue producing multi-layered backlit work.

RMC is now using the Durst for every flatbed test sample sent out customers. The company, which was set up in 2010, is a trade printer with 70% of its work for sign companies and the rest for exhibition businesses. It employs 22 staff and has a turnover of £2.5million, but is now running out of space in its Yorkshire location. This has led to plans for a £1million investment at RMC Digital Print’s base, which will include expanding production workspace and purchasing an additional cutting system.

Nicole Spencer, Operations Director at RMC Digital Print, said: “The quality on the Durst is the best I have ever seen. We have been hugely impressed. The other machines just don’t get near. Every flatbed sample that now goes out to customers is produced on the Durst.

“We needed to upgrade our flatbed systems because of a need to increase our capacity by at least a third plus the fact that the reality today is that there is a very tight turnaround requirement for trade clients, who use our services. We’ve been operating around the clock because the orders continue to grow.”

She added: “Durst always comes across as being an extremely professional organisation in every aspect and look after their customers well. It’s a company that really does care about their staff and their clients. We’ve been most impressed.”

Peter Bray, Managing Director of Durst UK, said: “The Durst P10 250 high speed system has been the perfect answer for RMC’s demand for further improving quality and performance, while opening up new business opportunities with their trade clients, for both signage and exhibition work. I know they have been impressed by the high levels of consistency.

“Durst not only produces the highest quality systems, but is also a people-friendly company that will always go the extra mile to help both staff and customers. We’re proud to be playing a significant role in Durst’s future growth plans.”

RMC first approached Durst at last year’s FESPA. Full production with the Durst P10 250 HS started at the end of February.

[Photo caption: Nicole Spencer with the new Durst system at RMC Digital Print]

-

Ottimo Digital installs UK’s first EFI Quantum 5LXr printer

8 Mar 2017

We’ve all heard about start-up businesses that began in a bedroom, garage or shed, that then go on to become a huge success. However, perhaps not all of them have managed that feat during the biggest UK recession in recent times.

In 2009, Nick Lindwall and Lee Crew took the decision to walk away from paid employment to set up Ottimo Digital, with a dream of building a successful wide-format print business on the simple premise of providing outstanding print and exceptional customer service.

Starting out in a bedroom-sized printroom in Newport, South Wales, and equipped with just one modest roll-fed solvent printer, the business grew rapidly. New business was won and customer retention was the default. This naturally led quickly to necessary investment in additional print hardware.

The growth continued apace and in 2012 the Ottimo Digital HQ was relocated to a 5000-square foot production facility, with a printroom now equipped with a wide array of printers including a 3.2m wide roll-to-roll and an 8’ x 4’ flatbed.

Fast forward to 2017 and that same printroom now boasts a large number of aqueous, eco-solvent and latex roll-to-roll printers, two UV flatbed printers and a 3.2m wide automated cutting table capable of cutting, creasing and routing.

Pride of place is currently occupied by the most recent acquisition: the UK’s first 5-metre wide EFI Quantum LXr5 printer.

The EFI Quantum LXr5 UV-LED printer – featuring powerful LED-curing technology with dramatically lower power consumption – is a seven-colour system with optional white ink and unique feature sets such as double-sided printing, wrinkle analyser and many more. The printer offers high-quality imaging with 7 picolitre greyscale imaging in resolutions up to 1,200 dpi.

Additionally, the Quantum printer benefits from labour-saving inline finishing and single-operator media handling capabilities. It sets a new benchmark in reducing waste in media handling, with only 40 cm of wasted material per roll.

The achievable print quality makes the EFI Quantum 5LXr ideal for exhibition graphics that are often viewed at much closer ranges than output such as signage, banners and billboards.

Ottimo Digital Director Nick Lindwall explains: “Our business is primarily in exhibition graphics for retail and trade, and late in 2016 we identified a need for a roll-to-roll UV printer big enough to cope with high-quality 4-metre high exhibition stand graphics printed as a single piece. We were also keen to streamline our finishing process as that might have become something of a bottleneck if we began producing output that was too large to fit on our 3.2m cutting table.”

Following investigation of the options available – and having spoken to EFI supplier CMYUK – Ottimo was recommended the EFI Quantum 5LXr, which offers the desired LED-UV ink curing, very high print quality, and – importantly – an in-built cutter that allows for the production of finished graphics straight off the printer.

Nick continues: “We were invited by CMYUK to visit the EFI demo facility in Belgium to see the Quantum 5LXr printer in action. During this presentation, it quickly became apparent that the Quantum ticked pretty much every box. We came away suitably impressed and were confident that it was the right machine for us. We placed an order with CMYUK shortly afterwards.”

Since installation last month (February 2017), and with the assistance of CMYUK, the EFI Quantum 5LXr has already begun to produce live customer work, with the first jobs being produced during the training process.

Joint Ottimo Digital Director Lee Crew comments: “We are over the moon with this latest purchase. Entering the 5m-wide market, along with our already comprehensive range of equipment, means that we are perfectly placed to handle absolutely any project that customers require.

“In addition to this, the Quantum is the only 5m-wide machine to offer full in-line cutting which will speed up our finishing process, enabling us to offer extremely short turnarounds.”

CMYUK’s Robin East concludes: “Ottimo Digital are such an impressive operation, they’ve got a very loyal customer base and I can only see them growing further as their capabilities lead to them winning more new business. The addition of the EFI Quantum now enables Ottimo to offer its clients faster turnaround and superb quality. We’re delighted that CMYUK has been able to play a part in helping Ottimo move on to the next level in the development of their business.”

[Photo shows: Ottimo Digital's Lee Crew (left) and Nick Lindwall (right) with the UK’s first EFI Quantum LXr5 UV-LED printer.]

-

Mimaki JFX200 powers Modex Exhibitions from 0-600 in 3 weeks!

1 Mar 2017

In automotive terms, 0-600 in three weeks might seem somewhat irrelevant, but for one Northamptonshire-based exhibition and display contractors, that sort of performance proved to be just what was needed to transform their business fortunes, following their investment in a Mimaki JFX200-2513 flatbed LED UV printer.

From its base in Croughton, Northants, Modex Exhibitions produces bespoke, modular exhibition stands and displays for clients as diverse as BAE Systems, Nat West and Nottinghamshire County Council. Established in 2003, the company has developed a simple but highly effective business model which provides clients with a uniquely designed ‘one-stop’ modular exhibition display package, which includes: graphics, flooring, furniture, lighting, installation & removal, all at a fixed price per square metre.

Director Rob Brooks takes up the story: “Modex Exhibitions is well established as a designer and builder of high quality, custom-modular exhibition stands, delivered at a realistic price. We undertake virtually everything in-house, but the one thing that historically we’ve never had the capability for was the actual print of the graphics panels, which we had always outsourced.”

Without any prior knowledge or experience in print operations, it was a chance meeting with the team from Preston-based Mimaki re-seller Granthams, which led to a demonstration of the JFX200 at UK Mimaki distributor, Hybrid Services, in Crewe.

“Within 20 minutes of the demonstration starting I was convinced that this machine was just what we needed to become almost totally self-sufficient as a business – the speed and print quality just blew us away!” continues Brooks, who was so impressed he didn’t really feel the need to check out the competition.

Placing an order immediately, the combined efforts of the teams at Granthams and Hybrid Services saw the machine duly installed by mid-January and starting to earn its keep within days. The new JFX200 has quickly established itself as a really important production tool for the business, making a significant contribution to the production of 30 to 40 display stands per month. As Brooks explains: “From a standing start at installation, within the first three weeks we had successfully printed more than 600 8’ x 4’ rigid Foamex display boards... all without a single problem!”

The Mimaki JFX200-2513 Flatbed LED UV Printer offers a choice of inks, including white and clear, providing unlimited creative opportunities. With the capability to print to a wide range of substrates, the JFX200 maximizes productivity by using industry standard (8' x 4') media on its 2.5m x 1.3m bed.

In addition to the obvious performance talents of the JFX200, the new machine has garnered much praise within the business for the ease of use that it offers, which has proved to be a very significant benefit for a business with no previous print experience. As Brooks himself concludes: “Investing in the Mimaki has turned us from Luddites to high volume printers in a few weeks ... and we’ve got the photos to prove it!”

For more information about Modex Exhibitions visit its website: www.modexuk.com

[Photo caption: Jim Marshall from Modex Exhibitions operating the JFX200]

-

Your Print Partner expands with further investment in Mimaki grand format printers

19 Feb 2017

Coinciding with its move to a new 21,000sq feet headquarters; Lincoln-based Your Print Partner (YPP) continues to expand with further investment in Mimaki grand format printers as it looks to offer an extended product range to both end customers and print companies requiring a trade print service. -

Stylize Display Graphics installs UK's first Agfa Anapurna H3200i LED

15 Feb 2017

Suffolk-based Stylize Display Graphics has installed an Anapurna H3200i LED printer with a dual roll-to-roll option and flatbed capability to replace its Agfa Anapurna M2500i. It is the first Anapurna H3200i LED to be installed in the UK.

Stylize is a versatile operation which, since it was set up some 25 years back by Neil Saville, has steadily invested in the latest technology. Along with the Anapurna H3200i LED Stylize has also recently invested in a Kongsberg cutting table, which enables the company to not only print on heat sensitive material but also to cut and finish a wide range of jobs it could not have coped with previously in-house.

“We first invested in an Agfa Anapurna M1600 nearly ten years ago. That printer was still going strong several years later when we traded up to an Anapurna M2500i. Then, barely a year later, we heard that Agfa was about to introduce the H3200i LED and decided straight away that we just had to have it,” explained Neil Saville, founder and managing director of Stylize Display Graphics.

The company now employs ten staff including Neil’s two sons, Kane who operates the new Anapurna H3200i LED and Damon who manages overall production.

“We use a great deal of acrylic material and often print white on the reverse. This work tends to be produced at best quality mode but even so the output speed is still impressive. The LED lights will provide a cost saving on replacement bulbs and now there’s no wasted time waiting for the machine to warm up. Ink adhesion is excellent and there is no need for a promoter. Then, most importantly, the quality is fantastic,” enthused Kane Saville.

Stylize has grown organically and the staff takes pride in everything produced be it banners, vehicle graphics, exhibition graphics or very large outdoor signage. This has been borne out by the fact that over the past 25 years the company has built a loyal customer following ranging from leading retailers, international pharmaceutical companies, hospitals and educational establishments.

“Each time we have invested in a new printer we have looked at all the options but I have to say that Agfa has always won the business. Added to this, we can rely on Agfa’s service and support, which is excellent. If space was not at a premium we would invest in another Anapurna H3200i LED, one as a dedicated flatbed and the other as roll-to-roll,” commented Damon Saville.

Now Neil Saville has his sights on a further development for the business producing large textile graphics for a number of Stylize’s customers.

[Image shows (l-r) Damon, Neil and Kane Saville]

-

Group101 stages a grand entry into direct-to-textile print

2 Jul 2016

Wide format print and signage specialist Group101 has expanded its offer thanks to a recent investment in an MTEX 5032Pro direct-to-textile printer - and it’s using the printer to not only deliver new soft signage solutions, it’s also creating ‘trussing’ for stages at gigs and festivals, and fabric backdrops for theatres.

If the company’s history was written into a play, this latest investment would be the fourth act since it was started up as a canvas printer by chief executive James Sahota in a very small bedroom seven years ago. Its quick growth meant the company moved into a production facility after around a year, then nine months later they moved again into bigger premises and introduced more large scale signage machines including a CNC cutter.

After another move they finally settled into a 10,000 sqft facility in August 2015 which also now houses their new MTEX 5032Pro, installed just before Christmas.

James said: “While we started out serving both trade and direct customers, we’re now a trade-only supplier, working mostly with signmakers, other printers and range of design agencies. It’s a great arrangement as it means our customers know that we’re not a competitor for their business and we can work together with our clients to develop new applications to meet their customers’ requirements.”

With the MTEX 5032Pro, Group101 is now able to print directly onto a range of textiles including Airmesh vent fabric (for fencing banners, cafe barrier graphics, crowd control railing graphics, building wraps, banners, displays, exhibition graphics, point of sale signage and so on), backlit fabric, blackout display fabric for where zero light shine through is needed, and stretch fabric for display frames.

James added: “The MTEX 5032Pro is a totally different beast from your standard wide format printer. It’s a bit like the difference between driving a car and flying a plane - there are more factors to consider than when you’re just loading a roll of vinyl or a board, such as how the material behaves, and the effects of heat, tension and torque. It was a massive learning curve, but when the penny finally dropped I just had a big grin on my face.”

James and a couple of his operators have learned to operate the printer, and while they offer a range of products, the most popular are the stretch fabric display frames.

James explained: “The stretch fabric display frames and pop ups are like a sock you pull around the frame - and they can have a massive impact at up to 6 x 3m. We do the finishing too so we supply a complete solution, with bespoke display shapes if requested.

“With the fabric we use customers can wash the material at 30 degrees to keep it clean and the displays can be packed up and carried over your shoulder in a bag similar to a rucksack. At the other end of the scale we can also now produce theatre backdrops on fabric rather than a foamex board, with a 15-20m seamless graphic that companies can fold up and put away.

As a fairly small and approachable team we build up a trust with our customers which means they’re able to get us involved as a consultant at the start of a new project and ask us what we can do to help them deliver the best solution for their client.

“Thanks to our new soft signage solutions the MTEX is becoming a firm favourite with our network of trade clients. With our exceptional prices, a comprehensive knowledge of all things print and state of the art finishing department, it’s no wonder our trade fabric printing department is growing month on month.”

-

Wilmot-Budgen to upgrade to brand new Zünd D3 following drupa reveal

8 Jun 2016

Following its unveiling at drupa, the brand new Zünd D3 digital cutting table will be installed at point-of-sale (POS) specialist Wilmot-Budgen.

Surrey-based Wilmot-Budgen invested in a Zünd G3 XL3200 with Board Handling System earlier this year, making it the first business in the UK to have the complete system. However, the company was keen to push its production even further and installed the Zünd G3 on the basis that it could be upgraded to the even more productive Zünd D3 following its launch on May 31st.

The company – a specialist supplier of print and POS to major retailers and leading brands – already used an older Zünd G3 XL1600 for the creation of prototypes, but was impressed by the increased automation offered by the newer models and the Board Handling System, so ordered an additional Zünd G3 table for its production department.

"We were the first business in the UK to have the Board Handling System and are really pleased with it," says Peter Burford, Operations Director at Wilmot-Budgen. "It feeds, cuts and delivers material automatically allowing for longer runs to be unattended.

"We had been keeping an eye on Zünd's R&D and when we were told about the new Zünd D3 we made the purchase based on having it installed after its launch."

Originally designed for the leather-cutting market and now re-engineered for display graphics and other applications, the Zünd D3 features two beams to significantly increase productivity while retaining the highest levels of automation, accuracy and safety. Four models are available – Zünd D3 L3200, Zünd D3 XL3200, Zünd D3 2XL3200, Zünd D3 3XL3200 – to cater for many different applications.

Wilmot-Budgen will be swapping out its existing Zünd G3 XL3200 for the new Zünd D3 XL3200, but keeping all of the Board Handling System elements at either end. This is possible thanks to the flexible, modular design of Zünd cutting tables, which allows expertly engineered tools and systems to be changed and replaced as users' needs evolve, retaining the table's performance and value over time.

"The new Zünd D3 is an extraordinarily efficient machine," says Peter Giddings, Sales Director, Zünd Plotting Systems (UK) Ltd. "The dual beam system multiplies production while retaining high levels of automation, meaning even more output for less effort.

"Many of our customers use their Zünd cutting machines on double shifts and even 24/7 operation, so we needed to meet demand for increased automation and productivity. Therefore we were delighted to unveil the new Zünd D3, alongside our colleagues at Zünd Systemtechnik AG, at this year's drupa event. Wilmot-Budgen will be sure to put it, along with the Board Handling System, through its paces."

For further information or to book a visit to Zünd UK's demonstration suite in St Albans, please email sales@zund.co.uk or call +44 (0)1727 833003.

[Picture caption: The Zünd D3 was revealed at drupa.]

-

Slam Signs invests in new SureColor SC-S40600 large format printer

6 Jun 2016

Signage and printing company Slam Signs has invested in a four-colour SureColor SC-S40600 large format printer. It is the company’s third SureColor - as it has owned an SC-S30600 since its launch in 2012 and purchased its eight-colour SC-S70600 in 2015.

Based in St Albans, Hertfordshire, Slam Signs provides a complete design and print service to a wide range of customers - from small start-ups to well-known nationwide companies - and has been in business since 2007. It produces a variety of products including vehicle graphics/digital wraps, shop facias and signage, window graphics, banners/roller banners, internal and external signage, POS and pop-up exhibition displays.

Purchased from authorised Epson reseller Papergraphics, the SC-S40600 is one of three new 64-inch SureColor professional signage printers launched earlier this year. Its new design and production features combine to offer market-leading quality at the fastest possible speeds – up to 58.4sqm/hr - with precise repeatability and long-term durability. The affordable, entry-level SC-S40600 features Epson’s PrecisionCore printhead and offers Slam Signs a precise and accurate way to create high-quality graphics on a range of substrates including clear film, vinyl, canvas and paper. Working in tandem with Epson’s new formulation UltraChrome GS3 inks, the printer produces a wide range of highly accurate colours.

Slam Signs business partners David Jorge and Jodie Banfather say the new SureColor range is impressive: “You can tell Epson have thought carefully about the design and build. Installation and set-up is straightforward and simple things like the addition of a large, clear LED-lit inspection panel for viewing the printing area once printing is in full flow make the printer easy to use. We know that we can rely on Epson’s engineering to give us high quality and productivity with full back-up and support should we need it.”

Slam Signs is particularly impressed with the speed and the highly accurate and repeatable colour reproduction of the SureColor range: “The output speed is excellent and the wider colour gamut gives amazing quality and clarity, whatever substrate is being printed, we can be confident that the colours will match consistently. I’m sure our customers are going to appreciate the results and I’m certain it’s going to open up whole new opportunities for our display and specialist applications.”

Phil McMullin, Sales Manager, ProGraphics, Epson UK, says: “Everything about the design of the new SureColor SC-S series is centred on improving the printing experience for the user and reducing cost of ownership. The printers lead the market in offering the very best combination of quality, speed and price and truly mark the pinnacle of Epson’s knowledge and expertise in one range.”

For further information about the new SureColor SC-S series printers, please visit www.epson.co.uk.

[Picture caption: Slam Signs used its new SureColor SC-S80600 to produce graphics for the Epson booth at Sign & Digital UK. It also produced a customised car, wrapped with the same design printed onto specialist vinyl.]

-

Soyang Europe invests in MTEX Blue dye sublimation printer for sampling and R&D purposes

6 Jun 2016

The recent investment in a new MTEX Blue dye sublimation printer by Soyang Europe has enabled the company to significantly increase its sample production and testing, benefiting its customer base with an improved service.

The ‘all in one’ direct to polyester printer features in-line fixation, resulting in output that is ready to sew and install – making it ideal for sign makers, graphics houses and production print operations looking to supply sublimation printed textiles for the retail, exhibition and display sectors.

“Soyang Europe has long been associated with textile substrates and with more companies looking to add the capability to their print portfolios, we saw the need to assist them as best we could,” says the company’s Managing Director, Mark Mashiter. “The MTEX Blue dye sub printer has allowed our sales team to demonstrate to customers what a printed fabric looks and feels like, rather than simply supplying an unprinted swatch – much to our and their benefit.”

The new printer joins Soyang’s R&D fleet of solvent and latex machines and helps accomplish important tasks for the company. “Having in-house print capabilities also gives us the means to test new products before bringing them to market,” continues Mashiter. “Equally, we’re able to assist customers in the field with any technical enquiries – having industry standard printers and inks means it’s possible for us to offer an extra layer of support for companies by using similar machines to theirs.”

Soyang Europe offers a broad range of dye sublimation printable textiles, including its own Far Eastern manufactured range of backlit, flag, mesh and display materials, as well as European manufactured fabrics from Endutex and Aurich Textilien.

“Textile is a huge growth sector at the moment and our range of fabrics ensures our customers are in a strong position to positively respond to any requirement that their customers may have,” concludes Mashiter. “From retail lightboxes to interior décor, exhibition stands and soft signage, we have textiles available in a range of sizes and for a broad array of ink technologies. The MTEX Blue allows us to supply a printed sample to our customers that perfectly communicates how well these substrates perform.”

The MTEX Blue dye sublimation printer is exclusively distributed in the UK and Ireland by Hybrid Services Ltd and the company’s National Sales Manager – Textile & Apparel, Stephen Woodall, comments: “Soyang Europe’s investment in the MTEX Blue very much underlines the printer’s capabilities – we’re hugely impressed with the output we’ve seen on their range of fabrics already and we’re confident it will prove an invaluable tool for sampling and quality control.”

Soyang Europe’s product range, which also includes banner, canvas, self-adhesive materials, floor and wallcoverings and more can be found by visiting www.soyang.co.uk.

The MTEX Blue dye sublimation printer is exclusively distributed in the UK and Ireland by Hybrid Services – www.hybridservices.co.uk.

-

Print On Cheadle moves up a gear with new premises and Mimaki kit

1 Mar 2016

Cheshire-based printers, Print On, has really graduated to a different league in recent months with a move to impressive new 6,000 sq. ft. premises on Lawnhurst Industrial Park in Cheadle. The company’s future ambitions are evident as you walk through the front door past a well-appointed boardroom and customer meeting room, to be faced with a large modern reception area, beyond which stretches a very impressive open-plan print hall.

The first thing that strikes you is the tidiness of the whole place – open plan work areas can certainly expose a company’s weaknesses to visitors, but not here; Print On is more than happy to lay its soul bare and proud to let its customers see exactly how the company operates.

With a core staff of just 8 people, it’s obvious that efficiency is the name of the game, with each member of the team having clear focus and direction and being more than capable of multi-tasking, including the family directors of the business, who are remarkably hands-on. As Managing Director, Alex Oldfield explains, “We’re a tight-knit family business. I get amazing support from my father and mother in their respective roles of Marketing Director and Financial Director and none of us shy away from getting our hands dirty – we take real pride in what we do and get involved on a daily basis in every aspect of the operation.”

The impressive premises suggest that the business is prospering in what many still consider to be a challenging economy, so how has Print On managed to develop so successfully? Alex’s father Keith is confident in his response: “We’ve always believed our two key assets to be our staff and the equipment we use and there’s been no shortage of investment in either.”

Print On has traditionally based much of its production capability around its impressive arsenal of four Xerox Versant digital printers, but became increasingly aware that the ability to offer a more diverse range of print services would be crucial to retaining existing customers and also developing new revenue streams. As Alex explains: “Some of our larger retail customers with whom we have really close relationships were placing their PoS or other wide format print requirements with other print providers. We really needed to equip ourselves to meet what seemed to be a growing demand in the sector. Investment in a Mimaki JFX200 flatbed and a brace of Mimaki JV300 production solvent printers sourced through our long-standing relationship with Mimaki reseller Granthams of Preston has really enabled us to stretch our legs and start producing a much wider range of products for our customers.”

Alex cites this significant upturn in business as the catalyst for the move to new premises in January of this year. “We spent a couple of months at the end of last year decorating and refitting the premises to meet our specific requirements and this included a dedicated wide-format area in a separate part of the building to house the array of new Mimaki kit.”

The team’s wide-format specialist, Matt Peters can’t speak highly enough of his new charges as his experience of working with them expands. “I’ve previously worked with other wide-format flatbeds which I’d always felt to be perfectly adequate. But the more I use the Mimakis, the more impressed I am with their performance – the print quality and the speed just blows me away! We hardly ever need to use the highest quality setting on the JFX200, as even in fast production mode the quality is really quite exceptional. I’m regularly printing 8’ x 4’ rigid boards with full ink coverage in around 20 minutes, at a highly acceptable print quality.”

As for the JV300s, Matt enthusiastically describes them as “real workhorses and ultra-reliable.” These two machines have obviously been earning their keep at Print On as evidenced by the fact that under the ink cartridge re-cycling scheme operated by Mimaki’s UK and Ireland distributor, Hybrid Services, over 400 empty 440ml solvent ink cartridges have been re-cycled in less than 12 months operation.

There’s a real buzz about the new premises as everyone seems to be focused on maximising the potential of the heady blend of a mighty impressive kit list and a comfortable and spacious working environment. Customers seem equally impressed, with increased levels of business coming from longstanding clients including many major multi store retailers, as well as a number of new high-profile clients.

As a large printed sign in the Press Hall declares: “Impossible is not a fact. It’s an opinion. Impossible is not a declaration. It’s a dare. Impossible is potential. Impossible is Nothing.” … great words from the great Muhammad Ali. Clearly the small and enthusiastic team at Print On is more than up for a challenge with the confidence that new equipment and premises has brought them.

Further information about Print On's services can be found at www.printonuk.com.

Mimaki's full product range can be found via its UK and Irish distributor, Hybrid Services at www.hybridservices.co.uk.

[Photo caption: The Print On team with directors Keith and Alex Oldfield pictured centre]

-

Nazdar inks from QPS meet Impact Sign Solutions's 'mission critical' colour demands

24 Feb 2016

Impact Sign Solutions says Nazdar 702 Series inks have helped it meet 'mission critical' demands for colour accuracy. The 24-year-old Buckinghamshire-based sign making firm prints signs for small and large businesses, museums, schools, colleges and high-street shops – where advertising for high-end cosmetics and watches has to be precise.

"We create our own colour profiles to ensure our colours are accurate – we perhaps place more importance on this than other businesses – and have found that Nazdar 702 Series inks are certainly compatible with that ethos," says Andy Borrow, Managing Director, Impact Sign Solutions. "Colour is mission critical for us."

Impact Sign Solutions has been running Nazdar 702 Series inks on its Océ Arizona 250GT flatbed wide-format printer for around six months, having had problems with the inks initially installed on the machine, which were from another manufacturer. Research on finding a replacement alternative ink led to Nazdar and its distributor Quality Print Services (QPS) Ltd.

"Nazdar is widely known – people always talk about their products at Sign and Digital UK and so on – and has a very good reputation," says Andy Borrow. "The Nazdar 702 Series has been really good since the switchover and we've had no problems at all. In the future we're definitely planning to move our other printers over to Nazdar digital inks."

However, the Impact Sign Solutions MD is safe in the knowledge that if a problem were to occur with Océ Arizona 250GT, Lancashire-based QPS would provide technical support straight away.

"The QPS engineer who installed the Nazdar inks on the Océ Arizona 250GT was a breath of fresh air: comprehensive and competent, explained everything thoroughly and gave training and tips to the team as well as dealing with the machine itself," he says.

Chris Bailey, Managing Director, comments: "Nazdar inks are specially formulated to provide a top-quality, reliable, colour-matched formula for specific printing systems at a lower price point than the OEM product. The Nazdar 702 Series inkset for Océ Arizona printer platforms is no exception and therefore an ideal choice for businesses like Impact Sign Solutions that have customers who demand vivid, true-to-life colours and densities.

"We certainly don't anticipate any issues but our UK support team is available should Impact Sign Solutions ever need it."

Andy Borrow concludes: "Honestly, it's a relief to find a team like QPS that both supplies the excellent Nazdar inks we need and supports the machine – it's the way business should be."

Nazdar will be showcasing the Nazdar 702 Series inkset alongside Nazdar 703 Series and Nazdar 705 Series inks – all designed for the UV plug-and-play inkjet market – at FESPA Digital 2016 from March 8th to 12th.

"Our new UV inkjet inks are designed to be direct replacements for the OEM inks, while offering significant savings to the end user," explains Rich Dunklee, Nazdar's Global Market Segment Manager for UV Digital Inkjet Inks. "Impact Sign Solutions has discovered the benefits of using Nazdar 702 Series inks on its Océ Arizona 250GT: reliability, colour accuracy and, thanks to QPS's renowned customer service and technical expertise, a complete support package."

QPS will also demonstrate a range of Nazdar inks on stand L10 at Sign and Digital UK 2016 from April 19th to 21st 2016.

For further information on Impact Sign Solutions, please visit www.impactsignsolutions.co.uk.

For further information on QPS, please visit: www.qualityprintservices.com.

For more information on Nazdar and its comprehensive range of ink solutions, please visit www.nazdar.com.

-

'Smart' sportswear for Macclesfield Rugby Club, thanks to Mimaki reseller

23 Feb 2016

Macclesfield Rugby Union Club is competing in the 2015/16 season with the benefit of sponsorship from local textile print specialist and Mimaki reseller, R A Smart.

-

Mimaki JV300 fits the bill for Dublin-based IQ Group

15 Feb 2016

Dublin-based IQ Group recently added a Mimaki JV300-160 and CG-160FXII to its portfolio of printing hardware through authorised Mimaki reseller, Reprocentre, and the company is 'delighted' with the investment.

The IQ Group is a vibrant company in every sense of the word. From the vivid and high quality print it produces, the positive energy and growth it has experienced since it formed 5 years ago, and even through to the dynamic team and bright and quirky premises, it’s a colourful company. So it’s not surprising that, when they decided to expand their hardware portfolio, the Mimaki JV300-160 solvent printer was befitting of a place in the company's print room.

“Quality is key to IQ,” explains one of the company’s Directors, Gary Upton. “The Mimaki JV300 provides great print quality and continuity of colour every time, regardless of changes in temperature, giving us the ability to colour match perfectly. We’re a reactive company; we offer a fast turnaround for our customers and the JV300 fits right in here giving us speed and flexibility. We’ve been really impressed.”

IQ, or Image Quest as it was formally known, originally started out as a print management service and signage company, but quickly evolved to incorporate in-house print production to make them more cost effective, offer faster turnaround times and give their customers more security and confidentiality. “We offer the complete workflow in-house,” continues Upton. “We have a creative design studio, a highly-productive print department and a team of installation experts, so we can guarantee a premium service and products every time. We do a vast amount of contract work and we need to be consistent on every level, including superior print output, which is exactly what we get with the JV300.”

IQ made the investment in the Mimaki JV300 through authorised Mimaki reseller Reprocentre. Reprocentre's Sales Director Eoin Honan explains: “We’ve provided a variety of hardware and materials for IQ over the last few years, but when they came to us looking for something to increase their productivity without compromising on quality or colour gamut we recommended the Mimaki JV300 solvent printer. It is super-fast and the SS21 solvent inks mean beautiful bright blocks of colour aren’t an issue. We also supplied a Mimaki bulk-ink system (MBIS) with the JV300 which gives IQ higher production levels by running the printer overnight and unattended on long runs.”

Further information about IQ Group is available via its website www.iqgroup.ie.

Further information about Reprocentre and its products and services can be found at www.reprocentre.ie.

Full details of Mimaki’s product portfolio is available via its Irish and UK distributor, Hybrid Services Ltd at www.hybridservices.co.uk.

-

New Roland printer from QPS ensures festive cheer at Nexvision

10 Feb 2016

Nexvision completes a successful Christmas period after installing a second Roland VersaEXPRESS RF-640 running Nazdar TX-650 dye-sublimation inks, supplied by QPS.

-

HP DesignJet helps New Jersey Search and Rescue save lives

9 Feb 2016

New Jersey Search and Rescue (NJSAR) installed an HP DesignJet T2500 Multifunction Printer (MFP) to produce large-format maps to aid in search-and-rescue missions.

-

Thermadent reaps benefits of digitised workflow thanks to Objet30 OrthoDesk 3D printer from SMG3D

2 Feb 2016

“Going digital is surely the only route for affordable dental technology, and I would say it’s a must for all forward-thinking dental practitioners.”

Merseyside-based Thermadent Ltd., an orthodontic dental laboratory company, recently purchased an Objet30 OrthoDesk 3D printer to help digitise its workflow. The printer was installed by SMG3D – the 3D print division of the Stanford Marsh Group – and Thermadent has reaped the numerous benefits of its newly-digitised work flow.

Since February 2014, NHS Dental Services has been requesting that pre-treatment and post-treatment study models are submitted digitally. This led Thermadent to look at investing in a digital scanner to convert bulky and difficult-to-store plaster study models to 3D digital models.

Matthew Garnett, owner and Managing Director of Thermadent, explains: “I studied the 3D print market and plumped for an Objet30 OrthoDesk 3D printer, which we sourced from SMG3D. Since installation, the printer has transformed our production processes.”

“Using 3D digital study models means there’s no longer any need to store the physical study models − and we no longer need to worry about plaster model disposal. What’s more, thanks to new GDC regulations, every orthodontic practice now has to keep a record of each patient’s tooth movement indefinitely. To store each patient’s plaster study models would quickly become impossible. With digital study models all you need is a safe, secure place to store the CDs that contain the files.”

Matthew also explains that using the printer in-house has reduced lead times significantly: “The Objet30 has been specifically designed for small to medium-sized orthodontic dental labs like Thermadent. It helps us digitise our workflow from digital file to model, accelerate our production times and increase production capacity cleanly and efficiently.”

He continues: “With our digital workflow, we are able to convert chairside oral scans into precisely accurate 3D printed models, quickly. Additionally – thanks to the precise tolerances and extreme accuracy provided by the printer – our aligners are more accurate and provide a much better fit.

“Going digital is surely the only route for affordable dental technology, and I would say it’s a must for all forward-thinking dental practitioners.

“The team at SMG3D helped me decide which 3D printer was best for my needs thanks to their informed and impartial advice. Their help with installation and integration of the new machine with my existing equipment meant I could get on with the training they provided straight away, which reduced set-up time for the new Objet30 to an absolute minimum. They provided a first-class service all round.”

Adrian Painter, director of Stanford Marsh Group, comments: “Dental professionals such as Thermadent are already reaping the considerable benefits of 3D Print in terms of increased productivity, reduced costs and improved patient experience. We’re delighted to be able to supply the relevant 3D print solutions and offer the support to enable them to seamlessly transition to a digitised workflow.”

SMG3D’s knowledge and experience of 3D Print is extensive as it has supplied 3D print technology into engineering environments for rapid prototyping and digital manufacturing applications for several years; Representatives from the company look forward to discussing the potential of introducing 3D Print into their workflow process with visitors at the upcoming Dental Technology Show (Birmingham NEC, 22nd- 23rd April 2016).

For more information about Thermadent, please email info@thermadent.co.uk, or visit www.thermadent.co.uk.

For more information about the Objet30 OrthoDesk 3D printer, please visit www.smg3d.co.uk.

-

Ivo Prints 'pushes possibilities' with new Reggiani printer

2 Feb 2016

Ivo Prints has purchased a new Reggiani digital textile printer from i-Sub Ltd, which it says has already seen it 'pushing possibilities' with design.

-

Photobox chooses five new-generation Epson Surecolor SC-S60600 printers to boost photo canvas production capacity

18 Jan 2016

PhotoBox has invested in five new-generation Epson SureColor SC-S60600 64-inch wide-format printers. The company has installed these alongside its existing fleet of 16 SureColor SC-S50600 printers in its UK factory to meet the ongoing growing demand for personalised photo canvases.

PhotoBox is Europe’s leading B2C personalised photo based printing company which puts its considerable success down to inspiration supported by the right combination of product, service, marketing and innovative technology.

Launched in 2000, today the PhotoBox Group encompasses seven brands – PhotoBox, Moonpig, Hofmann, PaperShaker, Sticky9, posterjack and PosterXXL – and employs about 1,000 people worldwide. Its five factories around the world turn digital photos into over 600 different personalised products - including photo canvases - for 30 million members across 20 countries.

James Lawrence-Jones, Group Technical Innovation Director at PhotoBox, is responsible for product and production processes. “Since 2013 demand for photo canvases has grown by 70% year on year and we have expanded our production facilities to keep pace and deliver the very best quality and service to our customers,” says James. “We wanted an ink-efficient printer that would deliver great quality at higher speeds and with maximum reliability and the new SC-S60600 ticks all the boxes. Our manufacturing challenges are unusual because we have to be able to print, finish and despatch a large number of canvases on a day, over 12,000 individual canvases a day 24/7 at Christmas for example, and we have to rely on the very best production equipment to meet our high quality standards and tight deadlines.”

The new, robust SureColor SC-S60600 roll-to-roll printer has been designed to meet the needs of demanding production environments where maximum quality and reliability are key. It uses Epson PrecisionCore permanent printheads in a dual CMYK configuration to deliver outstanding 1440 x 1440 dpi resolution and speeds up to 95.3sqm/hr (single pass) and 52.3sqm/hr (typical banner applications). The sophisticated media feeding system incorporates highly-advanced auto-tension control and wide-diameter pressure rollers to optimise grip and feed accuracy. As a result, operators can load a 45kg roll of media and leave it to print unattended with the confidence that the end result will be perfect.

Very quickly after installation of the new printers, James and his production team were experiencing the benefits. “The SC-S60600 delivers improved print quality at reduced pass rates and offers improved ink efficiency which, when combined with the almost 20% boost in print speeds, results in lower overall production costs,” he says. “The new automated maintenance feature is another benefit,” says James. “It maximises printer uptime and frees up our operators to focus on other tasks to keep the print room running at peak efficiency. Plus, the new improved media loading means accurate media set up is easier and quicker - which allows for long run, unattended printing with the confidence that quality will be consistent across all the images.”

Canvas printing at PhotoBox is a highly streamlined operation. Customers have a choice of three canvas grades, 17 different sizes up to 30 x 40 inch, and rectangular, square and panoramic formats. Images received online on any of the 18 localised websites are automatically nested prior to printing in full-roll batches on a SureColor printer. The rolls are then loaded onto an Esko Kongsberg cutting table, automatically cut to size and finished. The complete process – from order receipt to despatch – typically takes less than 24 hours!

“The SureColor printers are excellent and we work them hard around the clock producing stunning images for our customers. It’s a high stress environment and we need maximum production uptime so when we need it we have great support from Epson and Rockwell, Epson’s appointed service provider,” says James.

Several staff members have also attended the Epson SureColor Academy to ensure they get the best from their printers. “Quality is key for production whatever the time of year so we train our production staff all year round to ensure we’re ‘match fit’ ahead of peak. Our operators have gained a better understanding and expertise in getting the very best results from the SureColors,” says James.

“We have developed the new SureColor SC-S60600 printer to meet the quality, productivity, reliability and efficiency needs of demanding, high-volume customers, such as PhotoBox, and their experience confirms that this new model truly is a superb professional production printer,” says Richard Barrow, Senior Product Manager, Epson Europe.