Onyx Graphics and MS Printing Solutions today announced an agreement to include ONYX Thrive workflow software for the MS-JP3 printer in the graphic market.

Onyx Graphics and MS Printing Solutions today announced an agreement to include ONYX Thrive workflow software for the MS-JP3 printer in the graphic market.

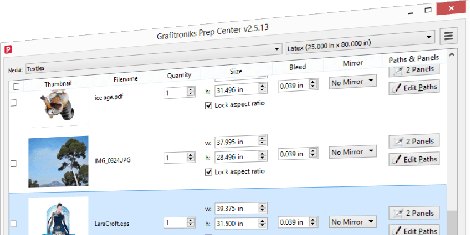

Zünd UK has announced the launch of Prep Center workflow software in the UK, with immediate availability.

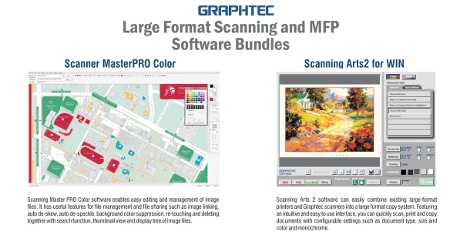

Paradigm Imaging Group has announce scanning and MFP software bundles included with all new Graphtec large format scanners: Scanning Master PRO Color and Scanning Arts 2.

Onyx Graphics has announced full support for the recently launched Epson SureColor® SC-S printers, through its proven wide-format print software. The Epson SureColor SC-S Series includes the SC-S80600, SC-S60600 and SC-S40600 models.

According to Epson, this new range of professional 64-inch signage printers combines robust engineering with new design and production features to deliver market-leading quality at the fastest possible speeds, precise repeatability and long-term durability. The new range gives print service providers a choice of printers to suit their specific production needs from 4-10 colours (including white and metallic) and up to 95.3sqm/hr of single-pass productivity.

ONYX software takes full advantage of the SC-S80600 printers’ unique capabilities, including support for 9/10 colour printing, using CMYKLcLmLk plus red and orange inks, as well as full support for white and silver ink configurations.

Specifically developed to make wide-format printing faster, predictable and more affordable, ONYX 12 software – which drives the entire SureColor SC-S Series printer line – enables print operators to print jobs right the first time. ONYX 12 software utilises the power of a next-generation, all 64-bit platform to harness full processing capabilities, delivering not just faster speeds but greater responsiveness as well. This version includes a redesigned user interface for easier navigation making it simple to find, view and edit jobs quickly. With new finishing tools, such as bleed and mark placement combined with full 64-bit processing, ONYX 12 software delivers the printing speed and finishing capabilities needed for the ideal Epson SureColor printing environment.

For more information, please visit www.onyxgfx.com.

Full end-to-end workflow integration for flexibility, productivity, profitability

With numerous successful installations at leading printing companies worldwide, integration of EFI™ (Nasdaq:EFII) Fiery® digital front end (DFE) technology with popular KODAK™ PRINERGY Workflow™ 5 and 6 solutions has helped users take advantage of best-in-class digital production automation.

Now PRINERGY Workflow 7 users will also be able to take advantage of this opportunity, and PRINERGY Workflow 5 and 6 users will be able to upgrade, keeping the same workflow automation in place. This unique integration, which offers bi-directional JDF communication, helps printing companies seamlessly blend their digital printing operations into a PRINERGY Workflow prepress and production environment.

"In this rapidly evolving print landscape, our relationship with EFI has been a critical factor in delivering essential workflow tools to printers eager for consistent, accurate and high quality print jobs," said Allan Brown, Vice President and General Manager, Unified Workflow Solutions, Kodak. "This partnership has been an essential part of Kodak's goal of providing innovative solutions for printers operating in hybrid offset and digital print environments."

EFI's newest Fiery DFE platform, Fiery FS200 Pro, gives printing companies the ability to move even more work to digital. With the Fiery/PRINERGY Workflow integration, users can access the latest Fiery DFE capabilities, including HyperRIP, a key Fiery job acceleration technology, for 55% faster job processing, advanced make-ready and colour management tools, right from the PRINERGY Workflow user interface.

PRINERGY Workflow users also can take advantage of the wide range of complementary EFI workflow solutions - ranging from Web-to-print and MIS to shop floor data collection and more - from the print industry's leading portfolio of print MIS/ERP and workflow software products. EFI's Monarch and Pace™ MIS solutions and its Digital StoreFront Web-to-print offering are also integrated with PRINERGY Workflow.

In addition, print shops with unique business needs can take advantage of the easy-to-use Fiery API (application programming interface) so that in-house developers can integrate their own custom applications or other third party solutions with their Fiery DFEs.

"We are pleased to continue our partnership with Kodak and to drive advancements through integrated Fiery/PRINERGY Workflow production environments," said Toby Weiss, senior vice president and general manager, EFI Fiery. "Our longstanding commitment to Fiery/PRINERGY Workflow integration not only gives users the advantage of a single workflow management system for offset and digital cut sheet printing, it also gives them the ability to connect to a broader range of digital printers from all leading digital printer manufacturers."

For more information about the productivity and profitability advantages available with Fiery Driven™ digital production printing and Fiery DFE integration with KODAK PRINERGY Workflow, visit www.efi.com.

Using an advanced highly automated and integrated workflow solution, featuring EFI™ Technique MIS software as its core, Belgium-based commercial print company Corelio Printing has achieved greater efficiencies to set itself above and beyond other publishing industry providers, with 85% of the company's multi-plant operation running hands-free.

Corelio Printing staff and customers benefit from this exceptional level of streamlined workflow integration as it allows staff to focus primarily on customer care instead of administrative or low-level production management tasks. The centrepiece of the workflow, EFI Technique software, schedules jobs with virtually no intervention across several plants running a variety of printing technologies.

The company, a division of Corelio Media, has also increased productivity while reducing costs because of the EFI Technique implementation and its integration to connect business management, prepress and production processes.

According to Corelio Printing CEO Jan Lynen, an influx of smaller publication runs in 30,000- to 50,000-quantity range created the need for faster turnaround. Without the EFI Technique installation, those jobs would have substantially increased the amount of labour needed to keep up with demand. "We produce from 12,000 to 20,000 plates per month," said Lynen, "but since implementing EFI Technique our customers' PDF files go straight to the platesetter with no staff involved.

"If a change comes in on a job," he added, "the software recalculates how many new plates have to be made and reassigns them to an available platesetter."

In the end, the successful EFI Technique implementation yielded a 10% savings in labour, according to Lynen. "Best of all," he added, "Customers love not having strict deadlines. Now they can upload files at their convenience 24 hours a day. All we need is a help desk for unusual orders. Technique gives our customers lots more flexibility when working with Corelio Printing."

Under its original ownership, Corelio Media printed the first issue of De Standaard, Belgium's largest-circulation newspaper, in 1918. Today the company's portfolio includes commercial printing, digital publishing and broadcast media, as well as newspaper publishing.

Much of Corelio Media's growth over the years is a result of a series of mergers and acquisitions from which it inherited additional printing facilities. In 2009, a reorganisation split the company's printing into Coldset Printing Partners for newspaper production and Corelio Printing for commercial applications including magazines and collateral materials. Housed in different facilities running heatset, coldset and sheetfed technology, Corelio Printing serves clients in Belgium, France and the Netherlands.

EFI Technique automates job scheduling in three plants

Lynen had several criteria when choosing workflow software to operate between the Corelio production facilities. "With the merger of several companies we had a mixture of processes and wanted to uniform production to save costs," said Lynen. "The software had to cover the operation of all of our plants and different technologies so JDF was very important."

EFI worked closely with Corelio Printing and its plate and prepress technology supplier, Agfa, to also establish a streamlined integration between Technique and the Agfa prepress workflow software Corelio uses.

Corelio Printing's next step working with EFI involves giving customers direct login access using EFI's proven Web-to-print technologies.

"EFI Technique has been a powerful MIS solution for customers around the world. Corelio Printing demonstrates how far a company in the publishing space can go with automation to reduce costs and improve customer relationships," said Paul Cripps, EFI's vice president of sales for the EMEA region. "We are honoured to be among its partners."