Hopefully, as a print business, you have now had the opportunity to ensure that your employees are safe from COVID-19 in accordance with government directives. Now, it is time to consider the potential impact on your printing equipment - and how to ensure it is ready to get to work following a business shutdown.

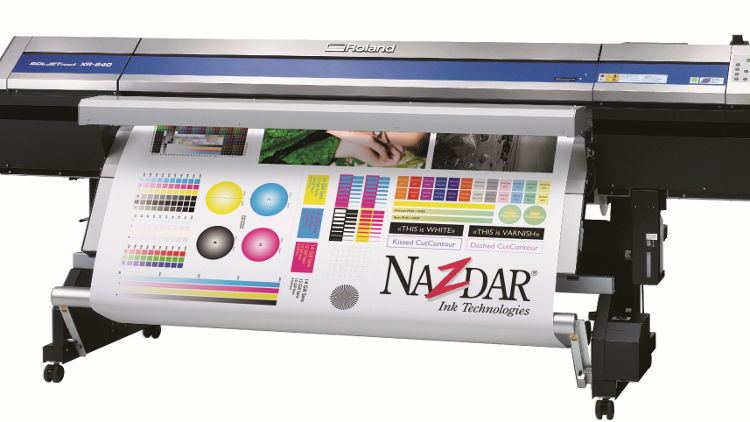

Large format printers are designed for heavy-duty use. Many businesses run their systems not just nine to five but 24/7, left to work unattended overnight before pulling a shift during the day, and manufacturers bear that in mind when designing various elements. Ink circulation systems, printheads and heating systems are all intended to work practically non-stop. This means that when printers are left idle or in standby mode for lengthy periods - for example during a shutdown - they may suffer damage. This could result in costly repairs, but can be avoided with some pre-emptive action.

Firstly, establish whether your printer manufacturer advises you to switch to standby or shut down completely. The user manual supplied with your device will provide instructions and guidance, while information should also be available online. Many manufacturers and suppliers have tech support teams working hard to help their customers remotely. You may be instructed to leave your machine switched on and in standby mode; some have automatic cleaning systems that work unattended, while some machines may necessitate manually printing a few metres of output every few weeks to keep things flowing. You could be advised to simply unplug and shut down, disconnecting all external devices like computers and scanners, and removing all substrates. Ignoring advice could void your warranty or service contract so it's important to follow it.

Stagnant ink is the biggest danger to your printer during idle periods - indeed at all times, so thorough cleaning should be a regular job - and white ink is especially prone to settling. If your printer has an ink recirculation system, carefully check the guidelines to determine what is required to maintain this. Unless you've been advised to flush your printer, you must ensure that the ink already installed has a shelf life that will exceed the duration of the shutdown. If not, consider replacing it before shutting down. This is because inks have been carefully developed to remain stable for a certain period, but not beyond it. Ink suppliers may not accept liability for inks that have passed this date and have caused damage.

Printheads are particularly sensitive and advice from their manufacturer should be followed to the letter to maintain them. Different types of printheads may require protection while mothballed; you may be advised to remove printheads and store them upright in their sealing caps, under the correct environmental storage conditions. In the case of UV, light-blocking material may be recommended to provide extra protection. Record the dates, times and processes you've undertaken, possibly delegating this task to a specific member of staff to ensure data consistency. Heating and cooling systems also need attention. Many manufacturers will advise turning off ink heaters as overheating an ink delivery system could cause ink instability. Again, follow all advice available to you.

As well as your equipment itself, consider your print room. Extremes of temperature and humidity could damage all of your equipment and consumables. Manufacturers and suppliers can provide information about safe parameters. If it's possible to control these environmental conditions remotely, set this up now. Cover up your machinery to stop dust and debris entering its components.

Finally, remember that you will be back working again soon. If you can take care of all those small maintenance jobs, repairs, cleaning and tidying, now is a great time. Prepare your equipment and workplace now to hit the ground running at the end of the lockdown. And if you need any type of advice, there is support available.

Authored by Chris Bailey, Managing Director, Quality Print Services Ltd