HumanEyes and EFI today announce their collaboration to provide customers with new and unique lenticular 3D printing capabilities using HumanEyes’s latest Producer3D technology. With the implementation of HumanEyes Producer3D software, the EFI Rastek T660™ now produces resolution enhancements that translate into superior quality lenticular.

The combined offering is being featured at PRINT 09 in EFI exhibit #2500.

“HumanEyes’s Producer3D technology gives EFI customers more flexibility and versatility to create unique package prototyping/short-run packaging, ad specialty items, display and exhibition graphics and indoor and outdoor signage,” says Darrell Etter, Director of Product Marketing at EFI.

“EFI and HumanEyes both strive to offer customers cutting edge technology at an affordable price point,” says Duby Hodd, CEO, HumanEyes Technologies. “Our latest HumanEyes Producer3D product allows EFI Rastek sites to offer their clients an expanded portfolio of options” .

HumanEyes Producer3D and EFI Rastek T660 Yield Powerful Results

With HumanEyes Producer3D it is now easy to create and print easily amazing lenticular printed projects with special effects: 3D, Flip, Zoom and Motion.

HumanEyes Producer3D maximizes printers’ productivity with an impressive array of new lenticular tools and industry first pre-press features that simplify the lenticular pre-print process, greatly improve productivity and provide superior print quality.

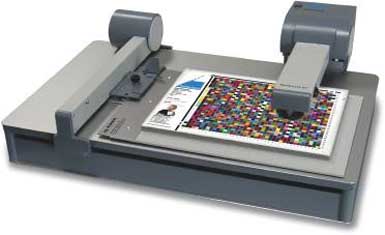

The EFI Rastek T660 is an economical and high-quality UV flatbed printer that provides production and print environments customer satisfaction and profitability through quick service, high image quality and a smaller footprint.

The EFI Rastek T660 generates photographic image quality with four- or four-color plus white, up to 1200 x 900 dpi and up to 300 ft²/hour (27.87 m²/hour). The Rastek T660 by EFI produces exceptional image quality, saturated colors and smooth gradations with gray scale print heads that utilize eight size drops ranging from six Pico-liter drops for fine detail to 42 Pico-liter drops.