Hamamatsu, Japan. June 18 2009 - Roland DG Corporation is proud to announce the release of the company’s newest 3D desktop milling machine, the MODELA MDX-40A. The MDX-40A builds on Roland’s advanced Subtractive Rapid Prototyping (SRP) technology with advanced features and bundled CAM software that together make it more versatile and easier to use.

Prototyping is becoming increasingly important to today’s product development professionals. The MDX-40A allows these users to create models from their 3D CAD data, lowering their product development costs and shortening the development cycle. The MDX-40A enables these professionals to create prototypes that reflect a product’s functionality and appearance, key factors that determine its value to consumers. For example, the MDX-40A can mill the design and actual texture of an automotive gearshift prototype so both can be reviewed easily for the highest quality results.

“The MODELA MDX-40A is an ideal prototyping solution for R&D and design departments of manufacturers and vocational educators, and particularly for those without previous milling experience,” said Masataka Otake, Roland DG 3D product manager. “The MDX-40A also includes Roland’s own CAM software, SRP Player, which further increases its ease of use and functionality. “

With Roland SRP Player, users simply follow a step-by-step guide to set up the milling process. From this input, SRP Player automatically determines the right tools and optimum tool path. Roland ClickMILL™ software is included as well, allowing users to round edges, add pockets and holes, create fixtures and add last minute modifications, all without accessing their CAD software. An optional rotary axis unit enables users to mill objects at any angle from 0 to 360 degrees unattended.

Along with this product announcement, Roland has announced that existing MDX-40 customers can update their SRP machines with some of the new features and capabilities of the MDX-40A with a simple firmware upgrade, available upon the release of the new MDX-40A.

Roland MODELA MDX-40A 3D Milling Machine Features:

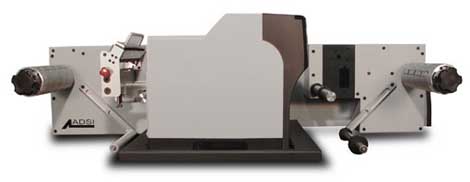

• Compact footprint of 699 mm (W) x 760 mm (D) x 554 mm (H) (26.34” x 29.9” x 21.8”) fits on the desktop.

• No special electrical installations are required and users can start prototyping immediately upon installation.

• Roland SRP Player CAM software is included and features simple step-by-step settings for easy operation and high quality milling.

• Roland ClickMill™ software is included and enables fast production and easy modifications. Users can surface materials, add holes and round edges – all without accessing their 3D CAD software.

• New on-screen operation panel offers additional functions, allowing the cursor to move in vertical, horizontal and oblique directions, and to a programmed position. It also allows users to adjust the speed of cursor movements for easier origin setting.

• A new optional rotary axis unit supports materials up to 270mm long by 120mm in diameter (10.63” long by 4.72” in diameter). This is four times the capacity of the previous model and large enough to mill a 500ml (16.9oz.) PET bottle.

• Supports NC code (G-code) for both professional and educational applications.

Roland Subtractive Rapid Prototyping Technology

Subtractive Rapid Prototyping (SRP) has several advantages over traditional additive rapid prototyping. SRP devices cost significantly less while producing prototypes from a wider variety of low-priced materials including ABS, acrylic, chemical woods, plaster and styrene form. With SRP, professionals can design prototypes using materials that closely match the substrate of the final product, so that the integrity and mechanical attributes of the design can be reviewed. SRP produces beautiful finishes with smooth curved surfaces, allowing designers to check the texture as well as the design.