GMG has announced a new release of its award-winning multichannel profiling software GMG OpenColor. The highlight of GMG OpenColor 2.0.4 is the ability to create separation profiles which can be exported to other applications. Following shortly afterwards, GMG OpenColor 2.0.5 will offer dot proof profiles for GMG proofing solutions.

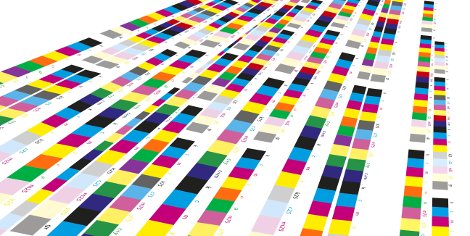

The sheer variety of printing technologies, spot colours, substrates and number of inks provide challenges for proofing. Especially the overprinting behavior, the interplay of inks printed on top of each other on the press, poses a major problem. To make proofing simpler (and better), GMG OpenColor calculates high-precision profiles and automatically transfers them to GMG ColorProof for printing. GMG OpenColor has received the PIA InterTech™ Technology Award, FTA Technical Innovation Award and a Technical Innovation commendation from the European Rotogravure Association for its groundbreaking overprint prediction capabilities.

Until now, the only way OpenColor profiles could be used was by creating proofs in GMG ColorProof. However, GMG has responded to the request of GMG OpenColor customers by offering separation profiles from OpenColor 2.0.4 that can be used in a number of places: within GMG ColorServer, Adobe Photoshop, and within packaging production software solutions. For example, users of GMG ColorServer will be able to use more sophisticated profiles to convert RGB or CMYK images to CMYK with OpenColor separation profiles.

Taking OpenColor profiles to the desktop

GMG has concurrently introduced an ingenious plug-in that allows GMG separation profiles to be imported directly into Adobe Photoshop: GMG ColorPlugin. With it, users can utilise GMG’s MX4 colour separation technology, including re-separation and ink optimisation profiles, on the desktop rather than in a server based environment.

GMG ColorPlugin comes in different editions: GMG ColorPlugin Standard works with all industry standard RGB-CMYK and CMYK-CMYK colour spaces. GMG ColorPlugin Pro adds the ability to implement custom colour profiles created in OpenColor 2.0.4 and existing ColorServer/ProfileEditor profiles, letting them match to a target colour space across a wide variety of printing processes and substrates. Due for release in May will be GMG ColorPlugin Packaging, which will offer the additional features of channel removal, minimum dot adjust and preview, and taking extra advantage of GMG OpenColor's spot colour profile functionality.

Easy integration into packaging production systems

Packaging is noted for print projects that include a large number of process and spot colours. The integration of a packaging production system with GMG OpenColor 2.0.4 will provide the most accurate colour separation profiles available. For example, GMG and HYBRID Software PACKZ recently announced that GMG OpenColor colour separation profile technology will be available within HYBRID Software's PACKZ label and packaging editor and workflow. This will allow PACKZ to use the colour conversion within its PDF editor to assure the most accurate transformations. This is particularly useful if the number of ink units are changed, or if the printer wants the most consistent representation of their brand colours.

Dot proof proofing profiles

Due for release in May will be GMG OpenColor 2.0.5, which allows the creation of dot proof (screen) proofing profiles for use in GMG DotProof and GMG FlexoProof. This is helpful for determining the overprint properties with the benefit of halftone proofing.

"GMG OpenColor is being used throughout the world by companies that are extremely impressed with the quality of their profiles—and the ease to create them—for proofs. They were so accurate that customers quickly started asking us to develop ways to use the profiles in other places," comments Paul Barnes, Product Management, GMG. "We believe that the use of OpenColor profiles in a packaging production system is a natural progression, given the benefits of its patented prediction model. Users will now find this very beneficial within Photoshop, editing images during the artwork and prepress processes."

GMG will be presenting these and other innovations at drupa in its own booth, at Hall 8A B10. In addition, GMG is also involved in the drupa innovation park (Hall 7 B15).

For more information please look at http://www.gmgcolor.com/products/opencolor/ and http://www.gmgcolor.com/products/colorplugin/