GMG, supplier of high-end color management and proofing solutions, is presenting GMG SmartProfiler, a user-friendly solution for the creation of ColorServer profiles, at Print 09 in Chicago from September 11-16.

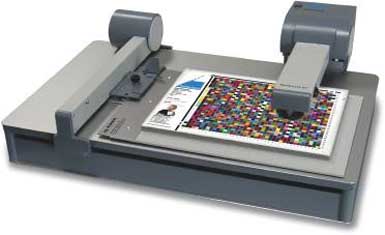

GMG SmartProfiler is a wizard which allows customers to calibrate and profile different output devices, such as digital presses or large format systems, easily and without profound knowledge of color management. The software is aimed at users who want to create their own profiles and/or calibrate output devices, or who work according to in-house standards, including flexo and packaging print houses who often face these challenges. All the necessary functions are available in GMG SmartProfiler, which will be available as an additional option in combination with GMG ColorServer 4.6 within the next 60 days.

Users, especially in the digital and large-format printing sectors, increasingly expect high color accuracy, repeatability and colors that match those of print media produced by classic printing processes, such as offset or gravure printing. Many digital printing and large format systems operate in hybrid environments, e.g. with digital and offset presses. There is a clear demand that the end product must look identical in all printing processes. Needless to say, the same also applies to companies where several output devices of an identical or similar type are installed.

With centrally controlled color management, companies can greatly increase productivity, production reliability and in particular the color quality of their products. Due to the identical quality of the printed output, flexibility in hybrid production environments is enhanced, because the output system to be used for printing can be selected at the last minute.

The creation of individual profiles and printer calibrations is now extensively assisted by a wizard. The software offers predefined settings for a wide variety of applications. Sources of error are minimized, since the user is guided step-by-step through the core applications of GMG SmartProfiler:

- Profile creation,

- Calibration,

- Creation of new calibrations and linearizations.

The high degree of automation in GMG's color management will help to cut costs, while increasing productivity and achieving consistent colors.

"In recent years, GMG has earned itself a first-class reputation with its trendsetting color management solutions for the graphic arts industry, especially for the traditional proofing business." says Paul Willems, CEO of GMG GmbH & Co. KG. "However, digital and large format printing, as well as flexo and packaging, are growing market segments which will benefit extremely from GMG's outstanding color management expertise. The potential uses for GMG SmartProfiler together with GMG ColorServer 4.6 are as manifold as are digital and large format printing applications, for example. Therefore, there is no doubt that our new solution will set important quality standards in these environments."