X-Rite and Esko will showcase a range of colour and workflow solutions at Drupa to help printers and converters successfully transition to extended colour gamut or fixed palette printing.

Package printers moving to extended gamut printing are able to match a wider range of brand colours than possible with four-colour process by using a more efficient seven-colour printing process. Combining X-Rite Pantone and Esko solutions with extended gamut printing allows printers to reduce job setup times and change over costs, support shorter job runs and improve turn-around times.

“Vibrant and colourful packaging can help a product stand out on the shelf, but achieving custom colours can involve cost and time constraints,” said Adrián Fernández, Vice President, PantoneLIVE, X-Rite Pantone. “Extended gamut printing opens up new colour palette possibilities for brand owners and converters without the added expense of spot colour printing. X-Rite Pantone is committed to helping printers close the gap between CMYK and spot colour printing by providing the tools needed for specifying, measuring and monitoring colour in an extended gamut printing process.”

“Increased product variation and lean manufacturing mean that converters today face the challenge of shorter print runs,” said Bernard Zwaenepoel, Senior VP Software Business, Esko. “Implementing extended gamut printing helps converters reduce press setup time and increase press efficiency. We are pleased to be working together with X-Rite Pantone, the colour authority, to deliver an integrated solution for converters.

At drupa 2016, May 31 through June 10 at the Düsseldorf Fairgrounds in Hall 8B A23, X‑Rite Pantone will showcase the latest digital colour communications and management solutions that support a converters transition to extended gamut printing. Featured products include PANTONE PLUS SERIES EXTENDED GAMUT Coated Guide, PantoneLIVE, ColorCert: X-Rite Edition and X-Rite measurement devices including X‑Rite eXact and IntelliTrax2. Esko will feature Equinox, an ecosystem of tools that help Converters to implement an Extended Gamut workflow.

The PANTONE Extended Gamut Guide

With the PANTONE Extended Gamut Guide brands, designers, and print suppliers can quickly visualise how Pantone reference colours will appear when reproduced using a fixed palette of CMYKOGV ink colours; even before moving ahead with a packaging project.

For the first time brands and designers can easily evaluate fixed palette approaches and better communicate colour intent to suppliers. Depending on the substrate, extended gamut will open up approximately 80 to 90 percent of Pantone colours, making many popular brand and corporate colours achievable using a fixed ink set. This allows designers to create more complex colour blending and cleaner transitions of colour in packaging design.

PantoneLIVE Helps with Colour Specification

When it comes to specifying colour, the PantoneLIVE cloud-based approach makes the sharing of digital colour standards easy and secure across the entire packaging supply chain from brand owners, designers, premedia, ink suppliers and printers. This ensures that everyone in the production workflow is working with the same achievable standards to drive colour consistency across different printing processes and substrates.

The PantoneLIVE spot colours are useful when extended gamut printing is employed. By using a common PantoneLIVE spot colour reference between fixed-palette and spot colour reproductions of packaging or labels, brands can achieve their desire for on-shelf consistency. PantoneLIVE has a wide ecosystem of supporting solutions, from design and editing of packaging graphics files, to colour separation, proofing, ink formulation, quality control and scoring.

X-Rite ColorCert Delivers Process Control

The foundation of a successful extended gamut print process includes the ability to control colour across the entire production process and across multiple locations. ColorCert: X-Rite Edition provides real-time monitoring of colour performance to ensure stable production and consistency of extended gamut colours. With ColorCert, users can create colour specifications and monitor production. A scorecard applies a score to each job, site or client based on specified colour tolerances.

The ColorCert approach to extended gamut is simple. The solution yields a score that reflects the overall quality level of an extended gamut run. This provides a fast and easy way to verify the process is in control. In addition, ColorCert provides the ability to drill down on any specific metric to support troubleshooting when overall quality levels indicate adjustments are needed.

X-Rite Colour Measurement Devices and Esko Equinox tools

When ColorCert and PantoneLIVE solutions are used in conjunction with X-Rite’s measurement solutions, converters are equipped to start transitioning to extended gamut printing in the pressroom. X-Rite’s family of spectrophotometers, including the new X‑Rite eXact Xp and the new fully automated X-Rite IntelliTrax2, offer accurate and repeatable colour measurements for extended gamut printing on a variety of substrates including flexible film.

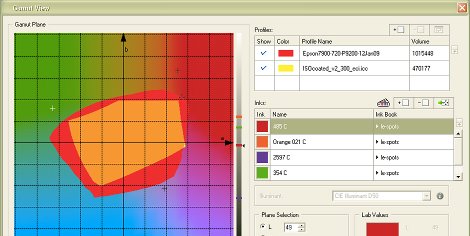

X-Rite’s sister company, Esko, offers Equinox to complete the solution for extended gamut printing. At all steps in the workflow, the Equinox ecosystem provides tools to implement Extended Gamut in a simple effective way. From fingerprinting the press, to conversion of packaging artwork, to gamut expansion of images, Equinox provides the right tools for the job. Artwork conversion can take place inside Esko’s high end packaging editors, or inside the Automation Engine workflow. Building these tools inside the prime platform used for packaging prepress makes adoption of the solution straightforward. An integrated contract proofing product, Pack Proof, provides accurate proofs of Extended Gamut jobs, giving converters confidence in the result before going on press.