Weerg extends the range of 3D printable materials with HP Multi Jet Fusion technology. In fact, a few weeks ago, the Italian service, which offers online CNC and 3D manufacturing, has introduced the use of polypropylene, joining the already widely recognized nylon PA11 and PA12 already available on the site.

The polypropylene represents an outstanding innovation for 3D printing with HP technology, which Weerg has tested as one of the first in Italy. With 8 already operational systems and 4 more coming by the end of the year, the Veneto-based company is in fact the largest European installation of HP Jet Fusion 5210 3D industrial printers to date. “We were anxiously awaiting the introduction of this new material, already widely used in industry for the production of pieces and components made with traditional technologies”, states Matteo Rigamonti, founder of Weerg, who attended as a testimonial at the Webinar organized by HP and BASF regarding the use of polypropylene. “Over the last year we have assisted to an exponential growth in the demand for 3D prints”, claims Rigamonti. “The pandemic has distorted the supply chains, generating in many areas a production urgency that has pushed many users to experiment with 3D printing and discover its undoubted advantages”. This is why there is a need for new materials to be used for industrial processing.

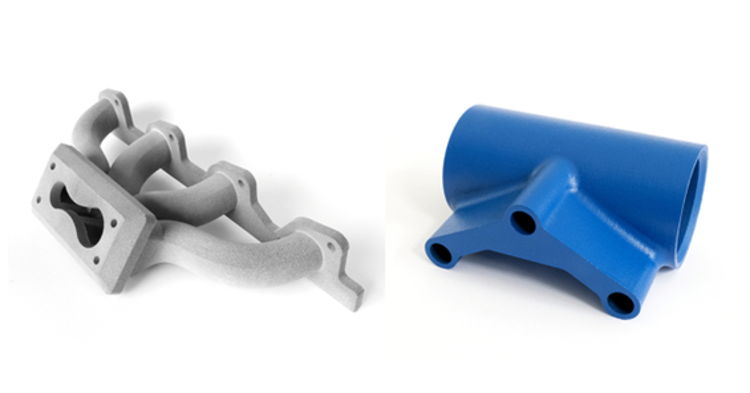

Being part of the semi-crystalline thermoplastics family of materials, polypropylene is characterized by an exceptional resistance to chemical agents, even the most aggressive ones, and to hydrocarbons. It also boasts a very low moisture absorption. Extremely lightweight (0,89 g/cm³), it is resistant to pressure and high temperatures, adapting to any welding technique, including infrared and ultrasonic welding. A plus that further expands its application areas as it allows to perfectly integrate 3D printed polypropylene parts with other components made of the same material but with traditional technologies, such as car interiors, pipes and tanks for the containment of fluids, mechanical components or parts of medical equipment. The use of polypropylene in prototyping also ensures greater compliance since it allows the prototype to be made directly from the same material used for the production of the final component.

“The performance of polypropylene processed with HP technology has proved satisfactory from the very first test phases, allowing us to obtain excellent results in terms of quality right away”, explains Rigamonti. “Prudentially we have indicated a tolerance of ± 0,60 mm, the printing tests we have carried out have reached tolerances of up to ± 0,30 mm, thus matching the performance offered by nylon, also in terms of flatness”. Cheaper than nylon, polypropylene requires slightly longer processing times, both in terms of printing and cooling, and this is a procedure that in Weerg is carried out only by a natural method. According to Rigamonti, the aesthetic performance is definitely superior.

“The surface is more even in comparison to the other materials, in fact it looks as if it has already been finished as soon as it comes out of the printer. However, its resistance to absorption prevents it from being dyed, except for the use of two-component RAL industrial paints, which we offer on weerg.com in red, blue, white, green and black”. Among the benefits of this material there is also the high recyclability of waste powders that can be reused up to 100%, with advantages both in terms of economy and eco-sustainability of the process.