Tilia Labs, Inc. (tilialabs.com), a leading developer of planning, imposition, and Artificially Intelligent automation software solutions for the graphic arts industries, teams with CERM and Esko to focus on the needs of sheetfed label producers in a collaborative workflow webinar.

Entitled “Integrating Your Label Workflow”, the free webinar will take place on June 23rd at 10.00 am EDT and will guide attendees through best practice and new capabilities to help sheetfed label converters achieve error-free print production.

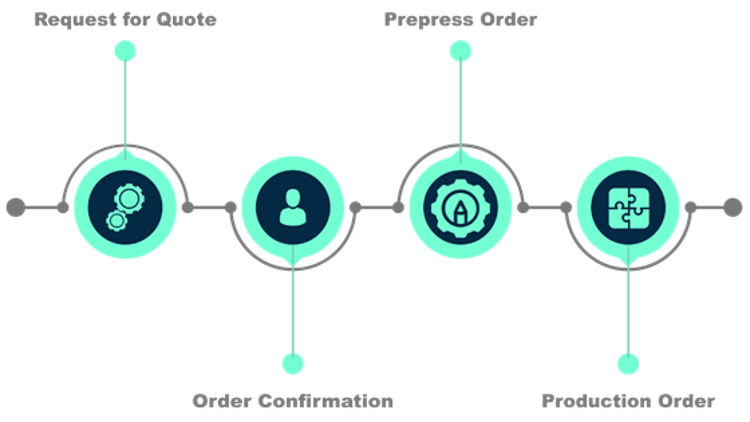

From the position that human data entry is one of the most common sources of errors in label production, the webinar will aim to illustrate that integrating and automating processes is essential for long-term viability and profitability. Using connected workflows and automated pre-production solutions from the three suppliers creates opportunities to:

• Quickly build and share quotes – Capturing order data in CERM via a wizard-driven quoting tool.

• Generate instant price estimates – Using CERM + Tilia Labs to achieve an integrated solution to streamline estimation.

• Harness the power of AI for production planning – Leveraging Tilia Labs Imposition AI technology to identify the most cost-effective combo plans in seconds

• Drive pre-production from MIS data – Using integrated workflow tasks including automated preflighting and print preparation with Esko Automation Engine & ArtPro+

• Manage approvals online – centralized web-based project management, control and validation using Esko WebCenter

• Own the process – quote faster, plan smarter, and reduce errors by employing best-in-class technology to simplify your workflow.

“When software suppliers work together, the industry as a whole benefits,” says Sagen de Jonge, CEO of Tilia Labs. “By collaborating with CERM and Esko we have combined expertise and technology solutions to deliver the kind of out-of-the-box systems integrations that businesses seek.The solution we will be showcasing for sheetfed label converters promises to be a real gamechanger.”