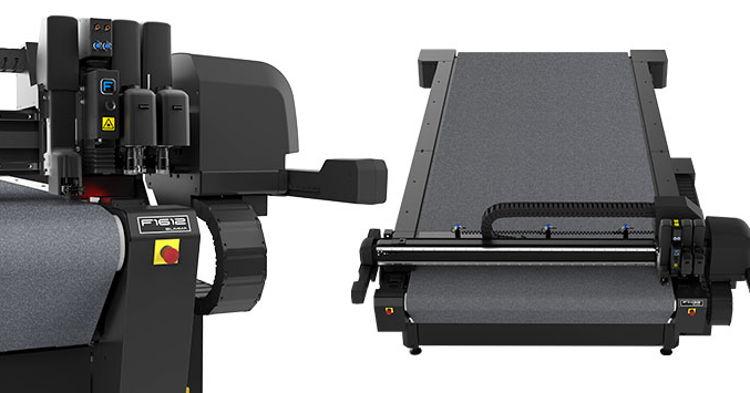

Summa is proud to announce a range of improvements on its renowned F Series flatbed cutters.

The flatbed cutters have been one of the most versatile products in Summa's range for many years. By improving the range, Summa brings its standard to the next level when it comes to quality, reliability and productivity. Summa is excited to present a new size of flatbed cutter, an enhanced safety system and its GoProduce software. These updates will contribute to an even better alignment of the F Series to realize present and future customer projects.

Meet the F1432: New size, new opportunities

The new F1432 flatbed cutter, available in December, accommodates users in the sense that it opens the possibility to process popular 137 cm/54" roll widths more efficiently. Moreover, the increased working length gives a sufficient margin to easily cut 3m/10ft jobs. For many businesses, this size represents the ideal interim solution between the F1612 and F1832 size.

Elice van Es, Summa’s Marketing and Communication Manager explains: “We are seeing a great fit in the market for our new F1432 flatbed cutter. The F Series flatbed cutters are appreciated for their versatility and performance and this new size underlines our philosophy. Thanks to the great number of applications that can be cut, we are convinced this flatbed cutter will benefit many customers’ businesses.”

Integrated Safety System for a safe and accessible work environment

Another major update on the F Series is the integration of a Safety System on all F Series models. The new system complies to worldwide health and safety requirements and thus represents Summa’s new standard in making the F Series operator’s work environment safer than ever. It features multiple sensors that can quickly detect human movement close to the machine. With the system’s convenient location on the top beam, the flatbed can now be accessed easily and safely. This in contrast to the former safety poles that are no longer needed.

Automatic Depth Control on the left side

The ADC feature on the F Series automatically sets the knife depth and the orientation of the knife/tool. The tip of the knife/tool is measured accurately and the down position of the tool is set to the flatbed’s level, guaranteeing a flawless cut at all times. This feature was already included for the right slots of the flatbed’s cutting head and proved its practicality. Now, Summa also makes ADC left standard available for all F Series models, which is the next step in efficiency enhancement of the Summa F Series.

GoProduce 2.0 software to perfectly match the F Series hardware

Along with the F Series enhancements related to hardware, it is the software that enables the operator to make good use of the machine’s functionalities. Therefore, Summa continues to develop its GoProduce software and now presents GoProduce 2.0. It is standard delivered with each new F Series and offers various new functionalities. While the standard integrated software includes many functionalities already, new is the availability of a Pro Pack. This Pro Pack is a one-time purchase and offers even more functionality to the F Series operator who wants to maximise his cutting workflow possibilities.

Elice van Es concludes: “Constantly listening to the market and analysing the needs of our customers is an important basis for us in the development of new products. We also believe that hardware and software should always be in harmony enabling us to offer users a complete solution and deliver true ease of use. Ready to create innovative and striking applications and tap into new markets. This is exactly what makes the Summa F Series so unique. The Series grows at the customer’s pace and needs alongside with evolutions in the industry.”