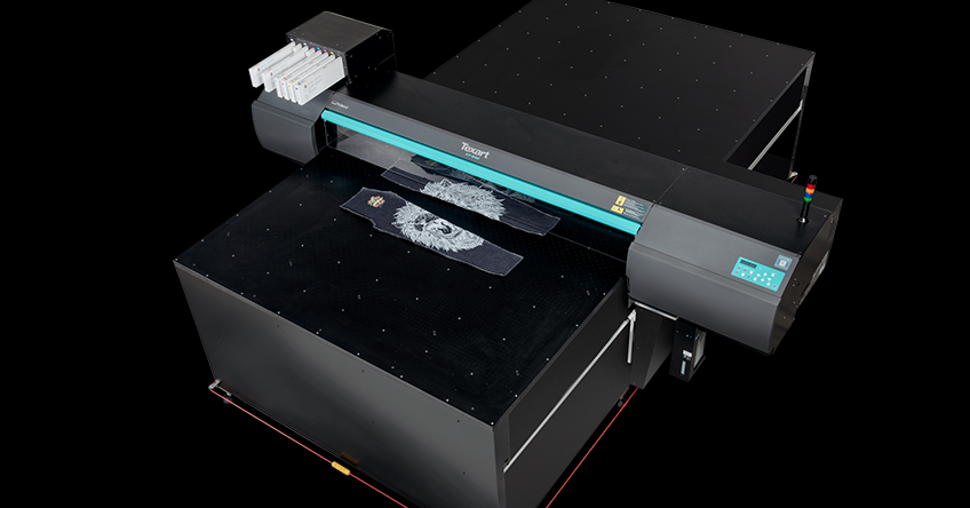

Roland DG has announced the launch of the new Texart XT-640S-F, a flexible, hybrid Direct-to-Textile and Direct-to-Garment solution designed to meet the growing demand for short-run printing in the apparel and textile industry.

A short run printer for the ‘drop’ generation

Inspired by the rise of limited-edition collections and ‘fashion drops’ - clothing items sold in small batches, heavily promoted via social media – the XT-640S-F is tailor made for short-run printing. A digital printer with virtually no set up required, it can decorate different sizes, colours and types of garment within the same print run, as well as seamlessly switching from Direct-to-Garment and Direct-to-Textile without changing machine.

Targeted at apparel print houses and garment manufacturers, the machine can be used to create fashion, sports and leisurewear, apparel and street attire. It is also perfect for fashion houses looking to build prototype versions of a clothing item or create a one-off piece for a show.

Paul Willems, Director of Business Development and Product Management at Roland DG EMEA comments: “In recent months, we’ve been working in collaboration with a number of our Italian textile customers to design a flat-bed machine that is purpose-built for the ‘fashion drop’ generation. The result is the Texart XT-640S-F, our most flexible textile printer to date, and a product that will help garment manufacturers to capitalize on the demand for short-run printing and incorporate it into their workflows.”

A flexible, durable and eco-friendly solution

The Texart XT-640S-F can print onto broad spectrum of fabrics including cotton, cotton-rich blends, white polyester, denim and leather. Its CMYK plus high-density White set-up delivers vibrant printing onto both white and coloured garments. With excellent wash test performance and ECO PASSPORT by OEKO-TEX certification, it also provides a high quality, eco-friendly solution for long-lasting results.

The product is available in three bed sizes, with a vacuum table included, and offers an optional jig system enabling up to six garments to be printed in a single workflow. Operators can ‘load and leave’ instead of constantly supervising the print process, freeing them up to focus on other activities. A 1 litre bulk ink system is also available to reduce printing costs and minimise daily tasks.

A versatile option for scaling businesses

The XT-640S-F is an agile, short-run-specific machine designed to sit alongside and traditional production methods. There are no setup fees and a simple digital workflow allows for low production costs and quick return on investment, with realistic print costs of around €0,50 per garment.

Willems continues: “Roland DG has always been known for leading-edge technology development across different ink technologies and is now evidencing its ingenuity in the textile print arena. This solution provides an affordable mid-range option to textile businesses who want to step-up or scale up existing operations, with the flexibility to deliver on their future growth ambitions.”

The Roland DG XT-640S-F is available across Europe, Middle East, North Africa and India.