Onyx Graphics, Inc. has launched a new addition to its suite of RIP and print workflow products. ONYX® Textile Edition software is designed specifically for the large format textile printing marketplace as an application-specific edition for ONYX RIPCenter™, ONYX PosterShop® and ONYX ProductionHouse™ packages and as a module for ONYX Thrive™ software.

ONYX Textile Edition software includes all the functionality of ONYX 11 software - such as Swatchbooks, sewing marks and disproportionate scaling - with the addition of textile-specific features that can save time and reduce waste. A single, simple process streamlines job preparation and offers the ability to run an entire shop using one RIP or print workflow product. ONYX Textile Edition software combines Step-and-Repeat, Colorways and Ink Configuration Builder functions with ONYX Color – Onyx Graphics’ proprietary colour engine - to increase the predictability of colour textile output.

“We understand that the right tools are critical in taking advantage of the rapidly-expanding textile market,” says Kevin Murphy, President of Onyx Graphics. “We’ve taken a vibrant, simple and smart approach to addressing the unique colour challenges in digitally produced textiles.”

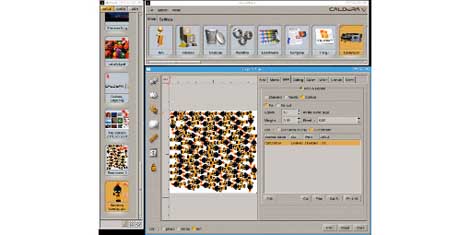

Step-and-Repeat functionality within the ONYX Textile Edition simplifies pattern creation by building repeating patterns with fewer clicks. Users can achieve unlimited layout possibilities with vertical and horizontal repeats, rotate and mirror options and the ability to add image offsets. The ONYX Step-and-Repeat function means users can quickly create edge-to-edge fabric and wall covering designs from a single repeatable image, eliminating the need for third-party applications. Users can experience substantial time savings when creating full-bleed repeats for any size material or application.

The Colorways function enables users to quickly create patterns in multiple colours from a single file by selecting from a specified Swatchbooks colour or manually selecting colours to produce unique patterns. Users can save valuable time because this simple, intuitive Colorways application eliminates the need to switch between multiple programs. The job setup function is achieved using the familiar ONYX interface.

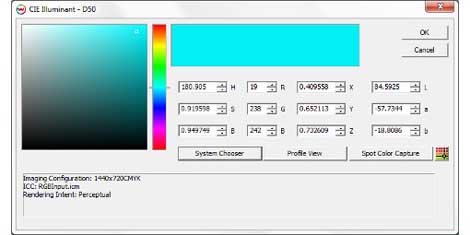

Textile printing has some unique colour challenges. Without the proper ink controls, colours can appear dull and less saturated. ONYX Color has been enhanced to overcome these colour challenges. Onyx Graphics’ proprietary colour engine delivers an expanded colour gamut that gives users the ability to match corporate colours, achieve deeper darks and print a wider range of colours. Available exclusively from ONYX, ChromaBoost™ technology allows users to achieve brighter, more saturated colours by increasing the chroma (the intensity of the colour) by as much as 40 percent.

The Ink Configuration Builder enables the quick creation of ink configurations for alternate ink sets (e.g. specialty textile colours) supported by a user’s print device. Specialty ink sets often come to market after a print device has been in service for a while, and its driver software may no longer be updated. The Ink Configuration Builder allows users to easily create their own ink configurations to support these specialty ink sets. In addition, the innovative Output Ink Reference chart gives users visibility to which ink is in which channel so they can easily determine the order in which the ink will print. The reference chart and ink configuration features included in

ONYX Textile Edition software let users accelerate printing by making changes to ink configurations during media set-up. Users gain control over ink and color to achieve predictable, vibrant results every time.

Availability

ONYX Textile Edition software is available as an edition for ONYX RIPCenter, ONYX PosterShop and ONYX ProductionHouse packages and as a module for ONYX Thrive software. To purchase ONYX Textile Edition software customers should contact their authorised ONYX reseller or visit www.onyxgfx.com for more information.