Germany-based Lindörfer + Steiner GmbH has selected the Zund G3 cutter with fully automated board handling system to improve productivity at its Bretten production facility.

The company, which was founded in 1995 by Klaus Lindörfer and Peter Steiner, specialises in the development and production of reusable transportation packaging for the automotive parts industry. It employs 50 people, has annual sales in the region of €10m and its key customers include Daimler, Audi, BMW, Porsche, Volkswagen and more.

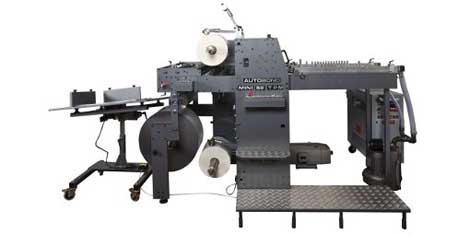

In 2011, Lindörfer + Steiner started thoroughly researching cutting systems that would speed up the finishing of its innovative packaging solutions.It also wanted to reduce the need for manual labour and minimise the risk of human error.Having considered the options available, it selected the Zund G3 cutter with fully automated board handling system (BHS). This system incorporates automatic board loading and unloading and was developed by Zund to meet the ever-increasing finishing speeds required by the display, signage and packaging markets.

In February 2012, the Zund G3 with fully automated BHS was installed at Lindörfer + Steiner’s premises. This has massively reduced the need for user intervention as all operators now need to do is place the uncut materials at one end of the machine and remove the stacked finished materials periodically from the other end. The system is also very simple to use, with the controls limited to a few basic settings.

Installation of the solution was quick and easy. Peter Steiner, CEO, Lindörfer + Steiner, comments “The process was very straightforward and successful and in no time we were able to swiftly cut and stack our packaging solutions.”

Once the system was live, Lindörfer + Steiner started to see immediate benefits. Mr Steiner explains, “The personnel costs were reduced by 50% in this area; the error rate was significantly reduced; and productivity has also increased significantly.”

The Zund G3 cutter with fully automated BHS can cut numerous materials up to 2m x 3m and corrections and changes can be made right up to the start of a production run. It has a completely modular automation that can be built up and retro-fitted as needed and – in addition to large finishing runs - it allows for efficient just-in-time production of shorter runs and even one-off projects.

A unique transport system allows for reliable stacking of cut boards without the need for bridges to hold cut pieces in place. This ensured that the separation of finished pieces from waste becomes considerably easier and more efficient. Cut boards are stacked automatically and can be easily removed with a pallet jack even while cutting continues. A pre-positioning system ensures that every board is accurately placed on the cutting surface - even when handling imperfectly stacked materials.

“Of course I would definitely recommend the cutter to other businesses. With the board handling system, I have been able to massively speed up our turnaround time and this gives us a real competitive edge.”

For more information on Lindörfer + Steiner, please visit http://www.ls-kunststofftechnik.com

For more information on Zund and its G3 and S3 range of cutters, please visit www.zund.com