High-graphic, efficient digital inkjet corrugated printing on EFI Nozomi C18000 ultra-high-speed single-pass inkjet printers continues to reach new benchmarks for packaging providers, including the achievement of another important certification addressing key recyclability needs.

Electronics For Imaging, Inc. has received an additional validation from the Western Michigan University (WMU) Recycling, Paper and Coating Pilot Plant – a leading certification organisation for corrugated recycling – that further verifies the recycling and repulpability of boards printed with white EFI Nozomi UV LED inks.

The WMU Pilot Plant provided an OCC (old corrugated containers) certification to EFI Nozomi white inks, extending the solid, research-driven evidence that Nozomi inkjet-printed corrugated boards can safely, efficiently and effectively enter recycling streams. This new certification follows the WMU Pilot Plant’s initial OCC certification provided for the EFI Nozomi C18000 printer’s CMYK four-colour process ink set.

EFI Nozomi inks are the first and only single-pass digital corrugated printer inks to achieve the certification, a key validation developed by modelling wax coating replacement protocols of the Fiber Boxboard Association, a group that represents approximately 95% of all U.S. corrugators. The ability to recycle digitally printed corrugated board remains an important topic as corrugators and boxmakers adopt single-pass inkjet to implement highly efficient supply chains that reflect their customers’ need for customisation and shorter order quantities.

Given the prevalence of OCC in packaging, the certification is important to ensure that corrugated packaging is safely recycled. According to the American Forest & Paper Association, on average, a corrugated box contains roughly 50% recycled fibre. Around 51% of OCC is used to make new corrugated board, with 11.5% used for boxboard materials, such as cereal boxes. An average of 92.3% of old corrugated containers are recycled according to AF&PA data, amounting to more than 32,000 tons worldwide.

In fact, corrugated reaches higher sustainably levels than other packaging options. Most corrugated fibres are recycled up to seven times, and that reuse of resources is a strong example of how corrugators and packaging converters can contribute to the circular economy.

“Sustainability is a key component of EFI’s R&D efforts, and this additional certification speaks to the growing opportunities the packaging industry has to adopt efficient, greener practices with corrugated board,” said Evandro Matteucci, vice president and general manager for EFI’s Packaging and Building Materials businesses. “The industry is already producing approximately five corrugated boxes per second worldwide using EFI Nozomi C18000 printers. With this new certification, Nozomi customers can be comfortable adding white ink to create premium boxes without worrying about any negative impact on recyclability.”

Greater versatility in digital corrugated printing with white ink

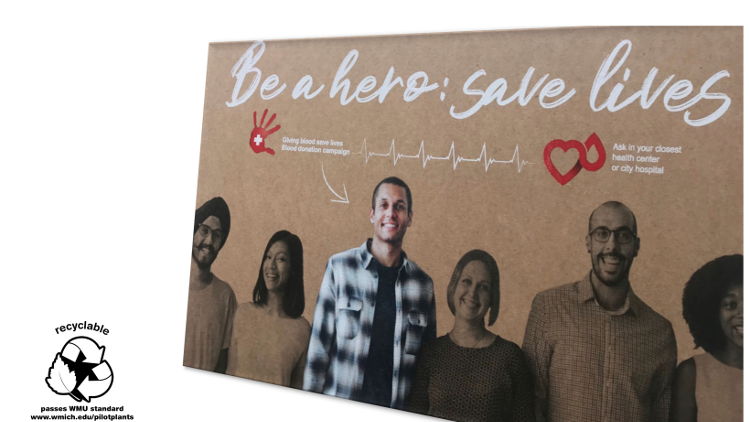

Using EFI Nozomi white ink underneath process-colour inks on corrugated boxes extends the colour gamut Nozomi users can achieve and gives them the ability to accurately represent their clients’ brand colours on brown kraft board. The white ink also allows for accurate printing of photographic images, including vivid designs, while maintaining the eco-friendly look of the brown board surface. Plus, Nozomi users can achieve a higher-value appearance for many jobs using white ink as a base under colour designs, as it transforms the matte appearance of CMYK inks on uncoated boards into a highly attractive gloss.

EFI UV LED low-odour inks are also GREENGUARD certified. They contain no hazardous volatile organic compounds and do not require vapor recovery. In addition, the print research institute Fogra has certified that the Nozomi C18000 is the most energy-efficient printer in its class based on the ISO 20690 Energy Standard. Digital printing with the EFI Nozomi C18000 printer generates virtually no waste due to make-ready or rejects and rework, compared to analogue flexo and litho lamination processes. All of this adds up to a smaller environmental footprint for packaging companies, while opening the door to new and profitable applications.

The EFI Nozomi C18000 prints at up 246 linear feet (75 linear meters) per minute; it can produce up to 10,000 35x35-inch (890x890-mm) boards per hour two-up. Its in-line primer allows dot gain and ink absorption control over a range of corrugated top sheets.

Users gain a distinct production advantage for cost-effective, on-demand and just-in-time jobs, fast-cycle proofs and prototypes, and customised campaigns. EFI Nozomi C18000 direct-to-substrate, production-level digital printing reduces process steps and costs – eliminating the long, up-front make-ready times and plate costs required in analogue processes.

Many of the world’s leading pulp and paper companies, along with independent corrugators, boxmakers, and display graphics producers, rely on the EFI Nozomi C18000 for high-graphic production. Several users have gained as much as 30% additional analogue capacity by transitioning analogue jobs to more-efficient production on their Nozomi C18000 printer. With installations in North America, Europe, Asia and Australia, it is the leading single-pass inkjet, direct-to-board corrugated printer.