Mimaki has announced that it is adding value to the print production process with the introduction of innovative software solutions that drive accurate, brilliant colour, attracting attention in an ever-more-colourful world. Three new software solutions highlight this innovative approach: the Artista Textile Color Collection; Mimaki Profile Master 3 (MPM3) for advanced printer profiling; and RasterLink6 Version 5.0. All are designed to help printers deliver accurate, repeatable colour across multiple devices and locations.

Digital Textile Printing: Coming of age

In the textile industry, the shift from analogue to digital production is underway as textile and apparel manufacturers aim at achieving faster time-to-market, reducing inventories and increasing flexibility to address rapidly evolving trends. Yet colour matching remains a significant issue due to the lack of a standardised colour chart that enables colour consistency from design through production. Mimaki is filling that gap with the Artista Textile Color Collection, making it faster and easier for textile and apparel manufacturers to achieve the desired colour without wasteful trial and error.

Mimaki intends to expand the collection over time, but it initially includes 520 colours for sublimation printing - including fluorescent inks - making it ideal for sports apparel and interior fabrics. By integrating the process into the workflow, the production of colour across multiple locations is made efficient and consistent.

The process starts with a designer specifying colours based on new swatches made available for Adobe Illustrator or CorelDRAW. An image file based on the selected colour palette is then printed on a Mimaki printer using either the RasterLink6 or TxLink3 RIP software. In addition to colour-accurate images, the resulting standard includes detailed information about profiles and settings that can be used to reduce the time required for colour matching, thus enabling colours to be represented accurately across printers and locations. The initial collection is designed for use with the Mimaki TS300P-1800 textile printer with dye sublimation inks.

Exclusively distributed in the UK and Ireland by Hybrid Services Ltd, the company’s National Sales Manager - Textile & Apparel, Stephen Woodall comments: “Controlling colour, including the new fluorescent shades, throughout the design and print process is a vital tool in delivering quality printed textiles. Mimaki’s focus on streamlining that is of significant benefit to our end users.”

Fast colour matching across media types and printers

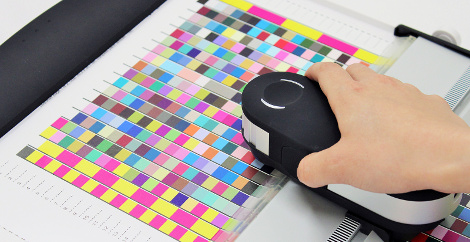

Media affects colour appearance, making it difficult to match colour across different media types and using different printers. Mimaki is simplifying this process with the new Mimaki Profile Master 3 (MPM3) colour management software. It enables users to reproduce equivalent colours when printing on different types of media with the same printer or when printing with different printer models and inks, vastly increasing the flexibility of a production platform, even when it consists of printers from multiple vendors.

It’s easy to use, requiring no special colour knowledge and speeds the integration of new printers into the mix, ensuring excellent colour matching across the entire platform. This makes it easier to split up larger jobs across multiple printers or produce projects that include pieces printed on a variety of printers, reducing cycle time and increasing quality and consistency. Print colour is consistently maintained over time by measuring colour with a colorimeter during the printer calibration process.

RasterLink6 now includes the PANTONE Color Collection

Mimaki’s market-leading printer RIP software, RasterLink6, now includes the PANTONE Color Collection, widely used around the globe for colour matching. This is in addition to the Adobe® Illustrator-compatible DIC colour collection and Mimaki’s original colour collections including metallic. PANTONE colours in print files are automatically detected and converted to equivalents for faster colour matching on RasterLink6-driven printers. This saves time, reduces waste, and is easy to use with no professional expertise required.

RasterLink6 Version 5.0 also delivers the ability to set a measured colour as a replacement colour, saving steps in the process. Frequently used colours can be stored in a customised colour collection for fast retrieval. In addition, this latest version enables the creation of cut marks for FOTOBA cutters. Marks can simply be placed on the RasterLink6 operation window without the need to use any other design software.

Available through Hybrid’s authorised reseller network, further information can be found by visiting www.hybridservices.co.uk.