Kongsberg Precision Cutting Systems (Kongsberg PCS) will demonstrate how the power, performance and versatility of its digital finishing solutions bring designs to life at next month’s FESPA Global Print Expo in Berlin.

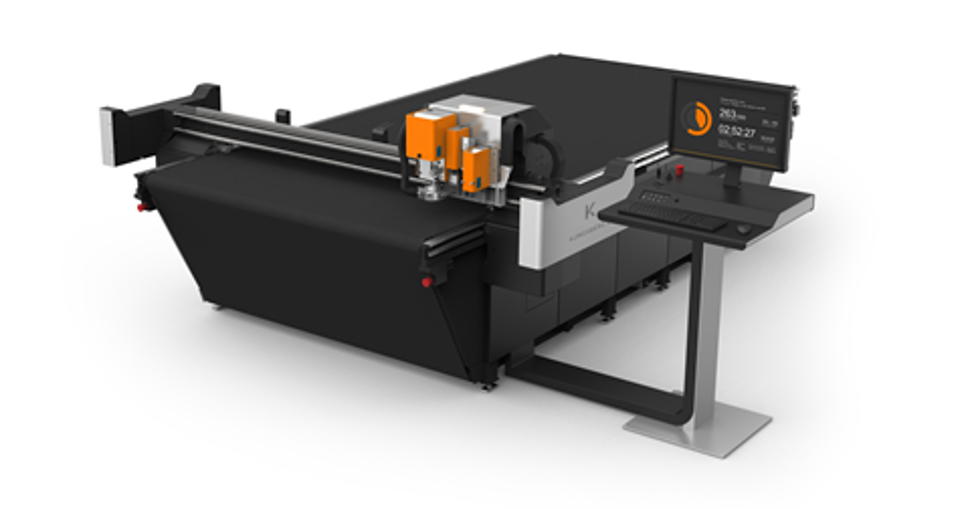

The company will showcase its flagship Kongsberg C Series digital cutting solution, its modular Kongsberg X24 table and the MultiCam Apex 3R CNC router on its huge display area (Stand C50, Hall 2.2) at the event held at the Messe Berlin in the German capital.

“We’re thrilled to be returning to FESPA following the success of our attendance last year,” said Wim Brunsting, EMEA Sales Director for Kongsberg PCS. “This year visitors can see even more of our systems cutting, creasing and folding a variety of materials. We’ll showcase how our range of digital finishing solutions enables sign and display businesses to streamline workflows and automate production to boost efficiency, while empowering designers and operators with the creative freedom to generate the ideas that will drive the future of their business. We’ll demonstrate how complexity is a thing of the past,” he said.

The Kongsberg C24 combines a steel tabletop with aluminum honeycomb core, a rack and pinion drive system and dynamic table mapping to deliver the greatest cutting accuracy and consistency. A maximum speed of 100 m/min (66 in/sec) and acceleration up to 1.7 G, combined with quick and precise tool movements, makes high quality digital production possible, even under the tightest deadlines.

“With our C24, we’ll demonstrate how a range of innovative Kongsberg tooling delivers new freedoms in design and creativity,” said Wim. “From our CorruSpeed tool, Psaligraphy knife and RotaCut tools, through to our manual roll feeder, i-camera and Fast Tool Adapter, visitors will get the chance to see how we have the tooling solutions to meet every need. We’ll also spotlight our amazing VariAngle tool - a breakthrough innovation for the industry that enables cutting at any angle from 0o to 60o at up to 100m/min,” added Wim. “Delivering total freedom in the design of 3D creative displays, it completely removes the need to stop production when changing tools, drastically reducing setup times and increasing cutting speeds.”

Across the booth, the Kongsberg PCS team will also be delivering continuous demos of the most versatile digital finishing device on the market, the Kongsberg X24. “In today’s volatile market, where both customer demands and capabilities of technology change rapidly, it is important to invest in equipment that offers the flexibility to grow in line with business needs,” said Wim. “The X24 delivers this, not just through its wide range of applications but also because it is a cutting table that can evolve.”

Wim said the team would be demonstrating add-on tools, such as the Kongsberg PowerHead, which excels on heavy duty material with its 150mm diameter crease wheels and equivalent of 50kg of downforce, and its FoamHead, which uses a reciprocating knife to handle foam materials. “This flexibility to add new tools for new materials, new applications, or more capacity means that with the Kongsberg X24, businesses can add volume and enter new market segments to meet the changing demands of customers or as part of a strategic plan for growth and diversification,” he said.

Wim and the Kongsberg PCS team will also showcase MultiCam’s flagship Apex 3R CNC router, one of the most versatile CNC Routers on the market that sets the standard for routing capabilities with its perfect balance between performance and precision. With spindle speeds ranging from 4-13.3 HP, the Apex 3R can cut a variety of materials including plastic, aluminum, wood, high-density foam, and composite materials.

“The APEX 3R features a heavy, all-steel tube frame that ensures durability,” said Wim. “It also makes the CNC machine more rigid, which reduces vibration and improves routing quality. The EZ Control operator interface, included as standard, ensures businesses can start routing right away and have minimal interruption in work processes, while a three-axis motion control system gives tight control over routing quality for precision and quality cutting.

“Automation is again made easy with the optional automatic tool changer, enabling operators to make cutting tool changes faster,” said Wim. “There’s also a fully programmable CNC knife that enables users to cut a wide range of materials such as rubber, foam, gaskets and textiles.”

Wim said with four days packed full of informative and inspirational ideas, this year’s FESPA was sure to be a huge success for Kongsberg PCS. “We’re looking forward to meeting visitors and sharing more about how our latest developments in digital finishing solutions can help them bring their designs to life,” he said.

To see the Kongsberg C24, Kongsberg X24 and MultiCam Apex 3R in action or to discuss digital finishing solutions, visit Wim Brunsting and the Kongsberg PCS team at Stand C50, Hall 2.2 at this year’s FESPA Global Print Expo, 31 May – 3 June 2022.

German software company OneVision will also be demonstrating the power and precision of Kongsberg PCS cutting solutions at FESPA. The company’s booth at Stand B31, Hall 3.2, will use a Kongsberg X22 table to demonstrate applications prepared in OneVision software.