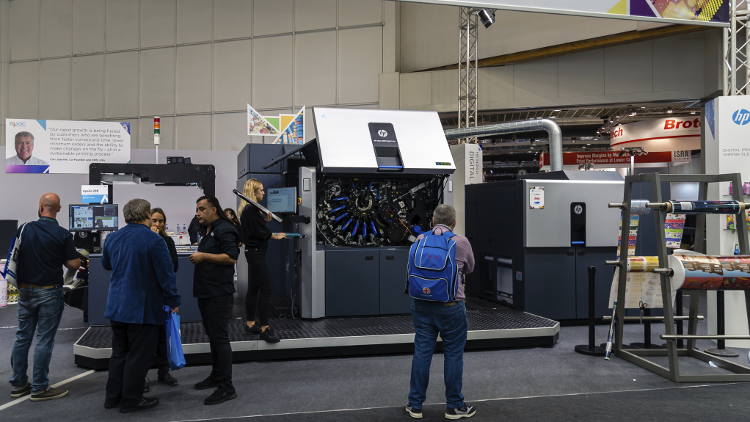

K-D Hermann GmbH contact Labelling Systems acts on the changed order situation in label printing and installs its first digital printing machine, the HP Indigo 6900.

After a thorough review of various digital printing systems, the investment in the HP Indigo 6900 was based on the consistent and good print quality and the printability of a wide range of substrates including thermal materials. Further, the food safety of the HP Indigo ElectroInk and the predictability of costs through the transparent click-cost model were decisive.

“The HP Indigo 6900 can handle any job for narrow-format labels, flexible packaging, banderoles, in-mold labels or wrap-around labels with a quick and easy job changeover“, said Konstantin Boelter, Area Manager Label Production at KD-Hermann GmbH.

The Hirschhorn-based company is one of the world’s leading manufacturers of labelling systems. In its 35 years of existence, the company has applied for numerous patents and now has an extensive network of experts with 100 employees. In addition to hand-held labelling systems, labels and label printers, the medium-sized company’s portfolio also includes labelling systems. In order to be able to adequately serve all production areas, the family-owned company particularly values its machinery and continuously invests in state-of-the-art technology. This now also includes the HP Indigo 6900 Digital Press.

“Our inquiries are becoming more individual, for example with sequential serial numbers or changing pictures on the labels. At the same time, print runs are getting smaller – the trend is clearly towards higher personalization and individualization. We had to react in order to continue to be able to handle enquiries economically. Digital printing can clearly show its strengths with these requirements. With HP, we have a strong partner at our side“, added Boelter.