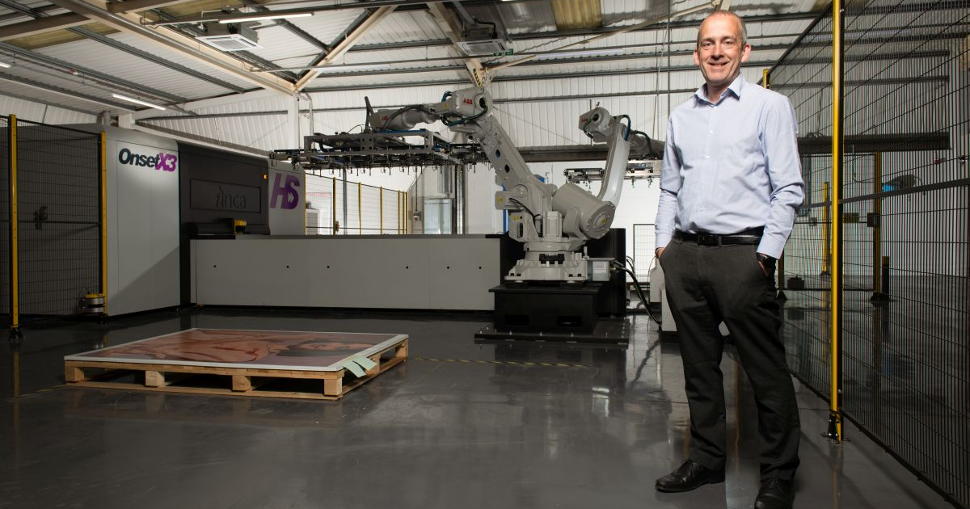

East Yorkshire-based full service PSP cites greater automation and capacity for work as key reasons for investment in the machine, which was installed in January 2021.

With 167 staff across three integrated production sites in the UK and an annual turnover of £20m, imageData is one of the country’s leading providers of print services for a wide range of market sectors. Whether it is point of sale, direct marketing, printed building wraps, marketing collateral or any print requirements, imageData works closely with its clients, which include many well-known blue chip brands, to develop bespoke automated solutions to exceed customer expectations. Helping to drive the business forward in 2021 is their latest investment, the Onset X3 HS Dual Flex from Fujifilm.

“Our customers expect the very best in quality and service,” says Glen Patrick, Commercial Director at imageData. “They demand fast turnaround times and high quality print at a competitive price and lead times are reducing all the time. In such a competitive market, you have to be on top of your game, so we need to ensure that we have the best print equipment available on the market.”

imageData already owns two Onset X3 presses from Fujifilm – the Onset X3 HS Dual Flex investment became the natural next step for the company, according to Production Director Pete Shaw: “We’ve had a long-standing relationship with Fujifilm stretching back many years, with numerous products from the Onset range taking pride of place at our facilities. The Onset X3 presses have been essential to our business, with the exceptionally high quality print and high speeds they offer. Now with the recent installation of the Onset X3 HS Dual Flex, our production speeds have increased threefold whilst retaining all the quality aspects that the range has always delivered.

“The automated capability of the Onset X3 HS Dual Flex is a game changer. The ‘High 5’ mode uses dual robots, so it can pick up the substrate, put it on the bed for printing, then pick it up and turn it over, and replace on the bed ready to print the reverse side – no human intervention is required, unlike our other machines where operators are required to flip substrates over. We’re mainly using this new press for rigid substrate production for the retail sector, keeping the other Onset X3 presses predominantly on paper-based substrates.

“The Onset X3 HS Dual Flex isn’t just helping us to produce work faster – it gives us another dimension to the way we run our business. The turnaround times are greatly reduced, not just because of the speed of the machine, but the fact that we no longer need to mask the bed is also a huge time saver in terms of overall turnaround - this feature can facilitate a job to job changeover time of just 30 seconds, which is highly impressive.”

Fujifilm’s ink expertise also played a significant part in imageData’s decision to invest: “Another benefit is the Onset’s ability to print white ink,” adds Patrick. “It works really well on clear, rigid substrates such as acrylic – something we have not been able to print onto before – so the new machine will help us to enter new markets.

“There’s no doubt in our mind that the Onset X3 HS Dual Flex is best in class at this time. We’ve enjoyed a prosperous, long-standing relationship with Fujifilm and look forward to reaping the benefit.”

Sean Connolly, Business Development Manager, Digital Solutions at Fujifilm Graphic Systems UK says: “imageData has benefitted from our Onset range for many years and now they have the chance to take their production to the next level with the Onset X3 HS Dual Flex. We applaud the positive approach they are taking to driving their business forward after a very difficult year for the whole industry and we are excited to continue to support them.”

Matt Brooks, Head of Products & Solutions at Inca Digital Printers, Fujifilm’s long-standing partner says: “We are delighted to have supported Fujifilm and imageData with the Dual Flex automation solution. When imageData showed an interest in Inca’s robot technology to compliment the Onset X3 HS, the Dual Flex system fitted perfectly. This offering is the most effective for flexible and rigid media. The solution, together with print and flip ‘High 5’ capability, offers a total end-to-end workflow, providing imageData with the greatest flexibility and efficiency. Inca is excited to see the first Dual Flex solution installed in the UK and looks forward to building and developing further solutions in the future”.