GMG has announced a major new release of its multichannel profiling software GMG OpenColor. Numerous new and optimised features have been embedded into a powerful new interface designed to make profiling more effortless and easy.

Simplicity is a challenge in a printing industry that is so incredibly challenging itself: the sheer variety of printing technologies, spot colours, substrates and number of inks trick packaging proofing into running a gauntlet of compromises. Especially the overprinting behavior, the interplay of inks printed on top of each other on the press, poses a major problem that could not be accurately simulated by previous proof systems.

To answer the challenge of making packaging proofing simpler, GMG OpenColor teamed up with the GMG proofing solution GMG ColorProof. Calculating high-precision profiles and automatically transferring them to GMG ColorProof for printing, GMG OpenColor turned out to be the missing component for seamless packaging proofing.

GMG OpenColor received the PIA InterTech™ Technology Award, FTA Technical Innovation Award and a Technical Innovation commendation from the European Rotogravure Association for its groundbreaking overprint prediction capabilities.

GMG OpenColor 2.0: Significant new features and user interface

GMG OpenColor 2.0 takes a major step forward. "GMG OpenColor 2.0 is a substantial upgrade to our first release," comments Victor Asseiceiro, Product Manager GMG OpenColor at GMG. "We conducted a number of customer interviews and leveraged information provided through our sales, service and support channels to help provide guidelines for this release. We feel very confident that we added and optimised features according to our target group's needs and made the software easier to use."

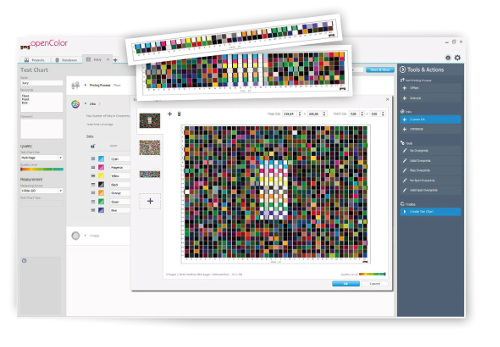

New look and feel: GMG OpenColor 2.0 comes with a completely redesigned user-centered interface. A project-based view allows more flexibility in handling measurement data and creating profiles, while at the same time providing more safety in terms of data control and transparency. Each packaging product can be managed via a project folder which holds all related information in one easily accessible place.

Centralised data storage and controlled data publishing: The centralised data management ensures accurate and consistent results even across multiple sites. Responding to the needs of production safety, GMG OpenColor 2.0 offers more control in terms of a publishing functionality so that only approved data and profiles proceed into production.

Color Correction Tools: GMG OpenColor 2.0 comes with extensive correction tools for determining potential sources of error, optimising measurement data and editing profiles. All corrections are visualised in a live preview.

Test Chart Generator: The GMG OpenColor multichannel test chart generator is the ultimate tool to create individual test charts for all packaging applications. Virtually any number of patches can be defined in various overprinting combinations and with full control of the separations. No current test chart generator is able to provide this flexibility.

Measuring Functionality: All test charts created with GMG OpenColor can be measured within the application. GMG OpenColor supports the most commonly used measuring devices in the industry.

"Based on results from major users and a number of awards, the use and performance of GMG OpenColor has never been in doubt," adds Asseiceiro. "However, OpenColor 2.0 becomes a much more significant application, with an easier user interface with easy to use connectivity to measurement devices, greater user control, and more power. Not only does GMG OpenColor continue to perform as an indispensable tool for major package printers; it now becomes an easier tool for smaller package printers, as well."

GMG OpenColor 2.0 is immediately available from GMG and GMG resellers.