GlavPrint, a Moscow-based company and long-standing Fujifilm customer, has a deserved reputation in its home market for reliability and quality in the creative production of advertising and display materials.

For more than five years, the company has centred its production around a Fujifilm Uvistar superwide format UV printer, which has operated reliably and efficiently over all that time at near 24/7 levels. When recent business growth prompted the company’s management team to explore their options for a new printer to run alongside the Uvistar, this positive experience with Fujifilm encouraged them to look closely at Fujifilm’s newest and most technologically advanced superwide format solution – the Acuity Ultra.

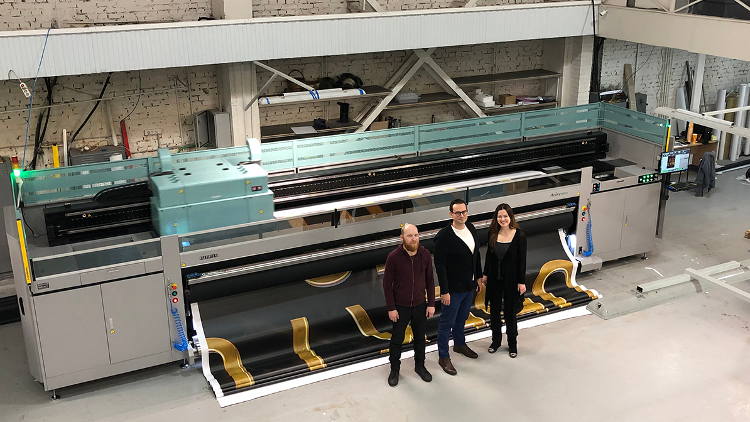

Not only is this machine the most advanced superwide format solution in the Fujifilm portfolio, GlavPrint came to the conclusion that it is currently the best superwide machine on the market. “The Acuity Ultra came out on top, by some distance, in tests we ran against all other competitor models,” says GlavPrint director Natalia Fomina. “And having becoming familiar with Fujifilm’s service organisation infrastructure in Russia, we were convinced that they could offer us the standard of support we required, even though this is the first installation of this printer, not just in Russia, but in all of Eastern Europe. The delivery of the printer took only three weeks, and the installation was carried out quickly and professionally.”

Sergey Belousov, Head of the Large Format division at Fujifilm Graphic Systems Russia explains just one of the many ways in which the Acuity Ultra was put through its paces by GlavPrint before they agreed to the investment. “They challenged us to print an even grey panel 45m long and 5m wide. Achieving consistent tones over such a large surface area is a hugely difficult task, but the Acuity Ultra handled this, and everything else that was thrown at it, easily. The management at GlavPrint was also hugely impressed with the value-for-money that the machine offers. They found competitor machines in a similar class to be up to twice the price.”

The printer comes in two models: 3.2m and 5m wide, with technologically advanced printheads enabling quality printing at speeds in excess of 200m2 per hour. Variable drop size technology from 35 down to 3.5 pl allows users to print at very near photographic levels of quality, and because the printer is built around a steel chassis, weighing more than seven tons, any effects of vibration on print quality during operation are eliminated. A state-of-the-art cooling system means that the Acuity Ultra, despite using conventional UV curing lamps, can print on even the thinnest materials without risk of them overheating.

“Every year, demand for large format printing for interior applications is increasing,” concludes Belousov. “It is not surprising that this is also helping to fuel an increase in consumer demand for ultra-high quality. Though a few years ago most consumers were satisfied with the print quality achievable with a 20pl drop size, now even a 10pl drop size is too large for the level of quality that many are demanding. Technologies to optimise print speeds and quality are evolving rapidly across the industry, and Fujifilm is proud of the role that it is playing in driving this innovation forward to bring maximum benefits to its customers around the world.”