SEPIAX Ink Technology GmbH has announced the imminent launch of the AQ160 printer, specifically designed to run the latest generation of SEPIAX Aquares inks, at the EcoPrint Show later this week. The company has also strengthened the distribution partnership with Reprographic Technology International.

The EcoPrint show in Berlin on 26th and 27th September will see the introduction of a purpose-built roll-to-roll printer, the AQ160, designed to exploit the capabilities of the Sepiax Aquares range of ink.

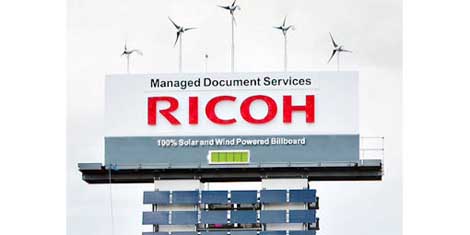

Following the success of the HP latex printers, the industry is seeing a shift to "green" solutions and a greater awareness of the impact on the environment of harmful solvents, non-recyclable materials and excessive power consumption. Major manufacturers are starting to consider the introduction of their versions of water-based, multipurpose, ink. For example, Mimaki launched the LX400 at Fespa in February of this year.

It was only a matter of time before SEPIAX Ink Technology GmbH, with some 5 years experience in, and a market-leading grasp of, the water-based resin surface-bonding ink technology, brought out a purpose built printer to use the ink for general sign-making and graphical applications.

In the UK a partnership is planned with Reprographic Technology International, a Canadian-based company with global reach supplying parts and consumables to the whole professional digital print sector, encompassing sheet and web fed production print, wide format plan print, labelling and display graphics. This partnership will provide the support needed to develop dealerships in the UK and Europe, with spare parts being held in the UK. This is a natural progression for the company's emergent Print Solutions Division.

Peter Barton, EMEA business director for RTI says, "I have been involved in the fascinating new technology of the Sepiax ink now for a couple of years, and I am excited by this new development in hardware. After various successful modifications to existing solvent printers being used in a range of semi-industrial processes, from the production of skis, flooring, room dividers, credit cards and even coffee mugs, the focus is turned to the signmaker and graphic arts printer, who wants to produce a wide range of media on a dedicated machine. This is where the AQ160 comes in. Built in Germany, the AQ160 is a 1.6metre roll-to-roll printer with specialized heating systems to ensure perfect curing of the SEPIAX Aquares ink. These precisely-controlled heating systems include pre-heat, under-platen heat, post-heat and even an infrared heating device on the carriage. There is also the option of a scanning "super" dryer to assist with speedy drying of highly hydrophobic materials. In spite of the demanding heating requirements the standard machine will consume not much more power than a standard solvent printer. Even the optional superdryer is using infrared scanning technology to minimize power consumption. The use of permanent piezo printheads also reduces costs and the consumption of raw materials."

Karl Ebner, sales and marketing director of SEPIAX says, "The EcoPrint show is the perfect platform for our company since we have been one of the first ones in this business defining 'ecology & green chemistry' as our company's principles. The latest market developments prove that moving away from harmful solvents and reducing power consumption are major steps for the graphics industry. Together with the theme of this show it confirms the direction SEPIAX had already chosen years ago."

Erik Norman, VP of Sales and Marketing for RTI says, "Although we are traditionally seen as a supplier of spare parts and consumables to the digital print sector, the rapid changes in this marketplace are leading to our clients asking us for advice on new print technologies. and this has naturally led to the creation of our Print Solutions Division. We have elected to work with leading print technology companies like SEPIAX who are the driving force behind this resin technology for inks, and you will be seeing other announcements from us regarding more leading-edge technology products, like solutions utilizing Memjet engines. We see these type of products changing the way our clients look at their print methodology."

All will be revealed at the EcoPrint show - the world's first event focused on sustainable print business.

“A lot of feedback for our latest ink improvement came from the industrial segment” adds Franz Aigner, CEO at SEPIAX with responsibility for the company’s product development. “In addition SEPIAX can be seen as the inventor of water-based resin inks for piezo printheads. We now have more than 5 years of experience with this new ink technology. Of course, our leading position helps to develop this technology to the next level while others are only now starting to launch their 1st generation products.”