Great margins thanks to large print runs—undoubtedly, many printing houses look back with nostalgia at the days when the number of units decided how profitable an order was. You set the machine up once and off you went. But the tables have turned: Print runs are shrinking in size, the number of jobs is increasing and delivery deadlines are getting shorter and shorter.

Therefore, many companies are having to consider the most uncomplicated and automated way to channel a growing number of printing orders through their business.

A company from Swabia is already mastering this perfectly: Elanders Germany. As part of the Swedish Elanders Group, the company in Waiblingen is unifying all parts of the Print & Packaging sector. Digital printing has been around in Waiblingen for decades. From monochrome digital printing and premium Indigo digital printing to premium high-speed inkjet printing: The plant is not only equipped with 8 HP Indigo digital presses and 3 HP Inkjet web systems, but also all types of finishing technology and bookbinding processes.

The main focus at the Waiblingen site is the production of adhesive-bound books with soft covers. It is not unusual for them to process over 1,000 orders per day. And this number continues to grow. The lion’s share of these are produced on inkjet web presses—the premium class of digital printing.

According to Peter Sommer, President of Print & Packaging at Elanders, success is based on two factors: First of all, an effective sales approach has to precisely understand each customer’s individual problems and convert these into solutions using the company’s capabilities. “It’s not just about printing a catalog anymore. A lot of people can do that. It’s about the entire process chain including logistics. In actual fact, we deliver operating manuals for cars directly to the production line. And, what’s more, we deliver them when they are needed.“

However, today, alongside sales, the processes implemented before and after printing also have a particularly decisive influence on the profitability of a company. This is where money is earned or lost. More than ever, automation and standardization are deciding how efficient the entire production process is, irrespective of whether the printing jobs are coming from open online shops, closed B2B portals or sales representatives.

“These (HP) web presses devour paper”, Peter Sommer jokes. “We feed them with orders that have a high level of uniformity. If you get tangled up with the size and printing substrate, you've already lost.”

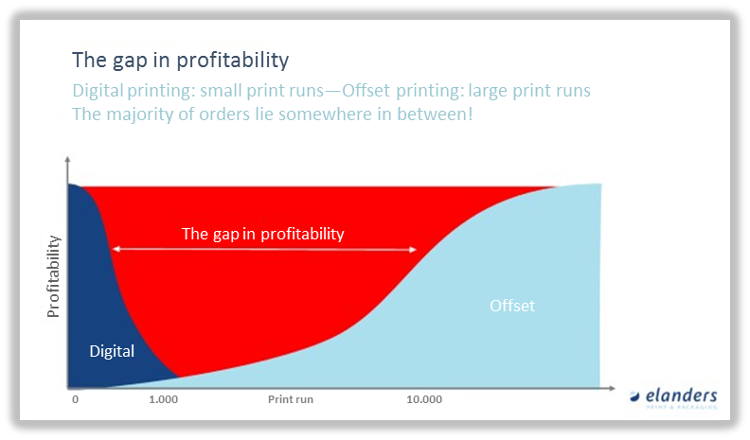

Inkjet closes the gap in profitability

Elanders started using the web inkjet in 2015. Alongside quality, the efficiency of the system was a deciding factor in terms of investment. For Peter Sommer, inkjet systems are the ideal way to close the gap in profitability between HP Indigos and offset printing. Small print runs with maximum quality standards are processed with Indigos. Large print runs with offset printing are often only cost-effective from 10,000 units onwards. However, the majority of orders are part of a middle ground.

“Using inkjet, we can cover everything that is too small for offset printing and too expensive for the Indigo” Peter Sommer confirms.

According to Peter Sommer, in some cases, customers can make vast price savings as a result. “If you look at the production costs of a 650-page product catalog (+ cover) with a print run of 500 units, you can save 45 % using inkjet compared to offset printing. The larger a book or catalog, the greater the potential savings. I always say “the thicker, the cheaper”.

At the moment, there are 3 HP PageWide WebPress T240 systems in Waiblingen alongside the appropriate finishing units. A fourth system is expected in springtime this year.

Quality and efficiency are not the only strengths that digital web printing has to offer. Its just-in-time and on-demand production brings many advantages, especially for digital book production. On the one hand, the profitability threshold falls when producing small print runs, but on the other hand, the costs associated with stock levels and disposing of remaining stocks have been reduced to a minimum. Digital web printing has also established itself in the direct mailing segment, where digital printing facilitates a personal approach based on data surrounding online user behavior.

Jürgen Freier, General Manager of EMEA HP PageWide Web Press, is sure that we can expect strong growth for inkjet over the next few years.

“Wherever there is a lot of data, specific and targeted products are also possible. In my opinion, that is the greatest advantage of digital printing, which won’t be fully exhausted for some time and still offers a lot of growth potential.“