Wide format is regarded as one of the most exciting areas of the print industry, with one of the main reasons for this being that every day is varied.

Each customer you deal with will want something different; every project will have unique specifications; and, to some extent, every surface has distinctive properties that will affect how a graphic film can adhere.

One of the main, stand-out trends in the current market is short-term branding for special events, pop-up stores and other promotional activities. This has led to a spike in demand for films with removable adhesives – products that adhere well to most surfaces, but are only required to do so temporarily.

While traditional removable adhesive technologies are proving popular with printers, once these materials are applied to a substrate, they don’t always offer a good option for repositioning or re-use if desired, thus limiting their use.

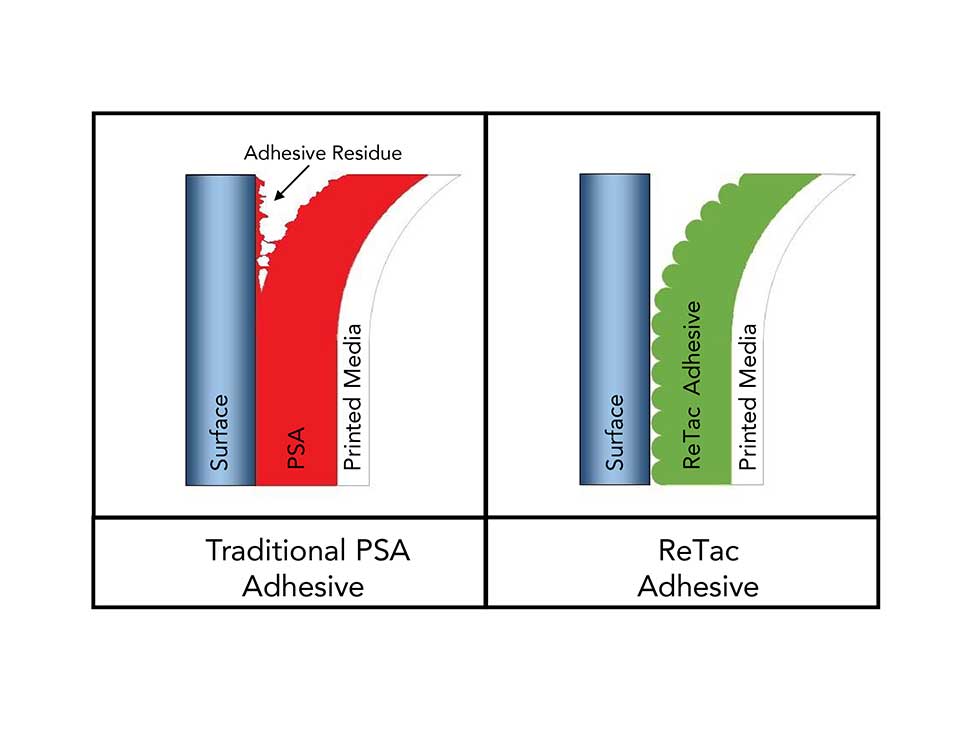

Then throw in the fact that the removable adhesive will provide an increased bond over time and can turn permanent after six months. This may result in difficulty removing the product, excess adhesive residue that needs to be cleaned up, or even worse, damage to the substrate, which might be a display window, painted wall surface or high-end flooring.

For situations like this, Drytac ReTac repositionable adhesive technology offers the perfect solution for printers, providing excellent adhesive qualities, with the ability to both reposition and reuse the graphics.

So, what is ReTac adhesive technology? What makes such a unique process possible? When Drytac formulates the ReTac adhesive, it uses larger spherical particles which, although individually invisible, together they have a noticeable effect.

When dried, these spherical particles will break up the continuity of the surface of the adhesive since contact is limited to the tangent point of the sphere. As such, this limited contact results in low peel adhesion levels, as well as removability and stable peel adhesion over time.

Comparing these products with typical removable adhesive technologies, the more traditional materials are produced using smaller adhesive particles, which, when dry, form a continuous film. These products create a larger surface area over which an adhesive bond can form, so peel strength will be initially higher and will increase over time.

While these products may indeed be removable, they are not intended for continual re-adherence, and as a result will limit the user to what they can achieve with their printed graphics.

So, what are the benefits of Drytac’s ‘microsphere’ adhesive technology over traditional options? First and foremost, Drytac ReTac is low peel and offers high removability with no residue. The fact it can be repositioned and reused means less waste over time.

As these materials are suitable for use across a wide range of substrates and surfaces, they make an ideal choice for use in short-term graphics projects such as wall graphics, temporary signage and repositionable notes.

Add in that they are friendly to the environment since they are water-based, and it is easy to see why ReTac is fast becoming the product of choice for many print service providers.

To further support customers with their choice of product when applying wall graphics and similar applications, Drytac has produced a dedicated Wall Surfaces Guide. This easy-to-digest guide sets out how the type of surface will have an impact on the adhesive bond of materials and offers expert advice on the different types of surfaces and how these may impact performance.

Authored by Glen Fitzgerald, Technical Sales Manager, at Drytac; and Daniel Farias, Technical Engineer, at Drytac.

To access Drytac’s Wall Surfaces Guide, please click here

To read additional recent news from Drytac, click here