Amesbury-based Digital 23 has taken delivery of a Mimaki UCJV300-160 UV LED print and cut machine from CMYUK. It joins an existing Mimaki UJV55-320 UV LED 3.2m printer that was installed earlier this year.

The new printer replaces a Mimaki print and cut solvent machine allowing the business to cope with additional demand and improve its production throughput.

“Business has been so good, and we needed to increase our capacity. We found that the Mimaki UJV55-320 was more economical to run than any of our other printers, so we were putting everything on it, but it was quite labour intensive to keep swopping 3.2m rolls for 1.6m ones every couple of hours or so. The UCJV300-160 has changed all that and fundamentally improved our productivity,” says Calvin Hedley, joint owner Digital 23.

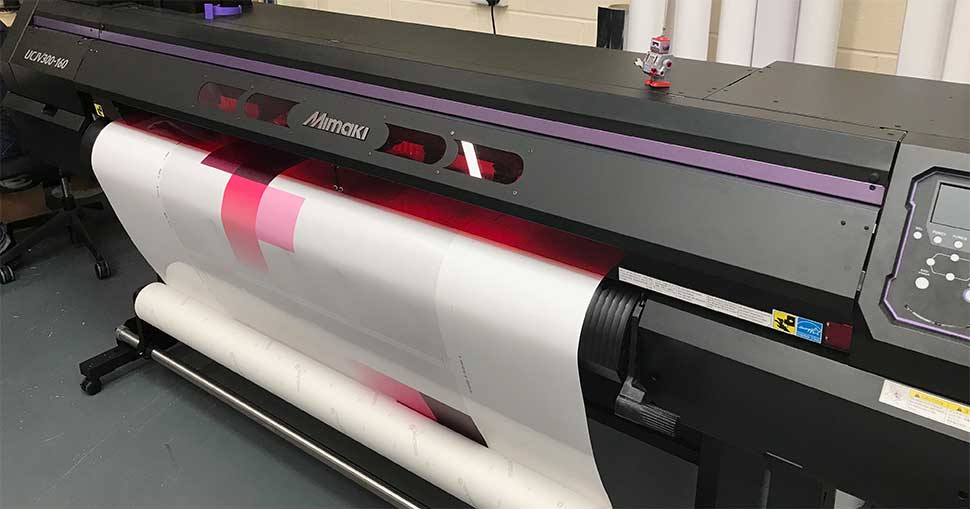

Mimaki UCJV300-160 UV LED print and cut machine

The Mimaki UCJV300-160 UV LED print and cut is a highly versatile piece of equipment. With a maximum resolution of 1200 dpi, it offers 4 inks layers, an inkset of up to 7 colours including white, all of which dry instantly. Digital 23 however, has purchased the standard 4-colour option. “We don’t print onto a white backing, our client base doesn’t call for that,” says Calvin.

The print and cut functionality of the printer was chosen to ensure that the relatively small volume of this type of finishing can now be done in-house. “As we don’t do that much, it costs quite a lot to subcontract this service out. It is far better for us to have the machine here and have the facility in-house than to have a third party cut vinyl for us. This printer replaced a solvent print and cut version too, so it was really replacing like for like capabilities,” he says.

Mimaki performance

Digital 23 invested in the 1.6m wide print and cut printer because it was so impressed with its Mimaki UJV55-320 printer. The 3.2m-wide UV LED roll-to-roll printer investment has enabled the business to print all its textile work in-house and provides a versatile platform from which it can create new business opportunities.

Running the business with Mimaki equipment has bought other advantages. “We had solvent and HP Latex print technology, so we had to hold materials for both. Now we can rationalise our stock as it all runs on both machines. Having two Mimaki UV LED printers has created a cross compatibility even down to using the same cleaning products,” says Calvin.

When we caught up with the company earlier in the year, the sectors that this company services – exhibitions and retail – were displaying robust recovery. Its forward-looking plans include moving into office refits and semi-permanent interior graphics.

Says Calvin: “Our printers give us the capacity to produce single wall coverings up to 3.2m wide or 1.6m wide drops, whatever our clients want. We’re really impressed with the Mimaki brand and it’s a manufacturer we are going to stick with.”