French RIP software specialist Caldera has announced the launch of a new product for June 2020.

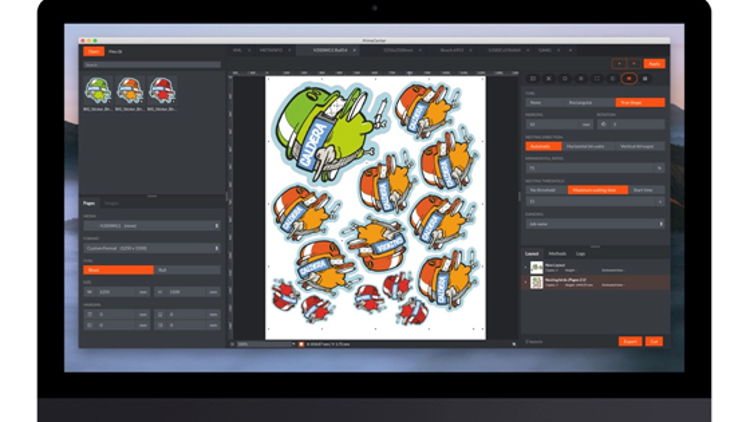

Caldera PrimeCenter is a prepress automation solution designed to help wide format digital printers to save time as they prepare jobs for printing. We are enabling the move from a “ready to print” to a “ready to produce” mind-set. Developed in cooperation with Zünd, this Caldera-owned and branded product will be available for delivery from mid-June.

This new software solution sits upstream from the RIP and has been created to fit easily into a Print&Cut workflow, enabling production to be scaled. PrimeCenter not only consolidates preflight, bleeding and nesting into one tool, it also reduces the level of manual errors, while saving time on file preparation. Different input image files coming in from clients – pdf, tif, jpeg, png – can be automatically prepared and optimized. These files are preflighted, marked and nested together, into “ready for production” layouts that save valuable prepress and production time. PrimeCenter doesn’t replace the RIP as it does not directly drive any printer or cutter, but acts as a firewall, preventing earlier issues at the production stage.

The Caldera PrimeCenter bestows multiple benefits for users. There are valuable time savings to be made during the preparation of jobs for Print&Cut production, resulting in increased automation and operator productivity. The optimized nesting feature will also generate media savings, as well as saving time spent on nesting and layouts. Manual nesting and cut marks are avoided. Production is streamlined thanks to the PrimeCenter’s ability to inject job meta data, and this contributes to complete workflow tracking using XML to connect to MIS and ERP solutions.

The target audience for the new product includes all sizes of print shop and the core users will be the prepress operators who prepare files for production. The PrimeCenter’s remit includes unique actions designed to automate roll-up, POS, stickers, backlit, banners production and more. For small, one-man operations this represents a significant time saving by allowing an owner-operator to use a dedicated interface that submits seamlessly to the RIP. For larger print operations, PrimeCenter reduces the multitude of repetitive daily tasks faced by prepress operators.

The new product comes in three distinct editions. PrimeCenter Basic requires users to manually apply a combination of actions such as preflight, nesting and bleeding in what we call recipes. PrimeCenter Pro represents a step up – the application of recipes is semi-automated via the automatic import of incoming files. Layouts are automatically generated, though not instantly exported to the controller or the RIP. The ultimate iteration, PrimeCenter Max, additionally automatically exports the layouts from the incoming files to the controller or the RIP.

According to Caldera’s Product Manager, Arnaud Fabre, “We’ve developed the new Caldera PrimeCenter to provide our customers with the right tool at the right place. Not only can they save time by employing this new prepress solution, but it’s optimization features can also result in substantial media savings too.”