The market for digital print for textiles is forecast to grow from €114.6m in 2009 to just under €1bn by 2014, according to a new study by Pira International published in association with FESPA.

Based on primary research and expert analysis The Future of Digital Print for Textiles: market forecasts to 2014 breaks down the global market by end-use sector, print process, region and country, with five-year forecasts to 2014.

The study also provides an up-to-date overview of the latest technology developments, analysis of the competitive landscape and identifies specific market opportunities for raw material and print technology suppliers. FESPA members can benefit from a special 15% discount.

The key findings from the study include:

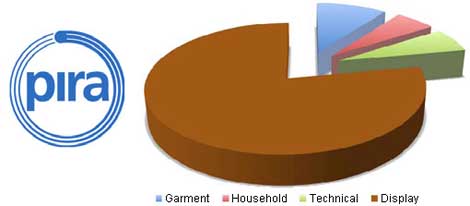

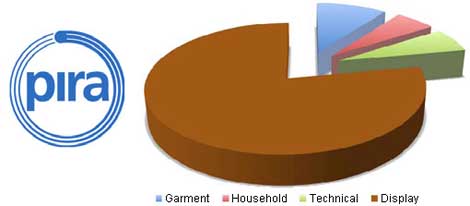

- The display/signage sector is driving the development of digital print for textiles as inkjet printers have had a longer experience in the market

- Textiles production has moved to countries with low labour rates, but digital printing may change that. Short runs and agile manufacturing are set to force some production back to North America and Western Europe. More of the cotton that is shipped from the US to China will stay at home, to be made into fabric that will be digitally printed locally to satisfy design-savvy consumers locally, while digital print will allow more designers to create and test new designs more quickly.

- Eco-solvent inks are replacing solvent-based inks as many of the older solvent machines are replaced, and environmental regulations in Europe and North America support the continued development and use of eco-solvent approaches.

- The total installed base of digital printers for textiles is forecast to grow to 52,800 units globally by 2014, a CAGR of 23.1%

Digital printing of textiles has been in effect since the mid 1990s with electrostatic (e-stat) and early wide format inkjet printers, either by direct printing (in the case of inkjet) and via dye sublimation transfer (inkjet and e-stat). Direct to fabric printers, combined with growth in textile applications such as soft signage and garments are driving the market for digital textile printing.

Because display/signage has been one of the first markets for inkjet printing, it is naturally the largest today. It is only in the last few years that dedicated fabric printers evolved and began to affect the garment, household, and other markets.

Inkjet printing is distributed globally. According to the study, the fastest-growing regions are the emerging markets of Eastern Europe and Asia, though it is important to remember that the pattern of growth is not the same for each country and region. Although there is a correlation between nations that are large textile exporters, it may not follow that digital printing will be dominant in those countries.

Marcus Timson, corporate communications director at FESPA explains FESPA’s support for the Pira study: “It was important for FESPA to gain a scientific view of the future direction of the digital textile market, and Pira was a credible partner to undertake such a comprehensive piece of analysis. FESPA’s screen printing heritage is such that printing onto textile has always been a very significant element of our events. More recently, our FESPA Digital shows have reflected the market’s migration towards digital textile printing for the short-run applications identified in the Pira study, and we have encouraged our community to explore the market’s potential through two Digital Textile conferences in parallel with these shows. The textile area of our flagship FESPA show has grown to the point where FESPA is now effectively the largest textile printing event in Europe, and the garment decoration segment will now have a dedicated zone at FESPA 2010, under the distinct FESPA Fabric banner. The Pira study, which is available at a discounted price of €3,555 for members of FESPA’s national associations, will help us to shape the events, products and services that FESPA creates to address the textile printing marketplace, and help our global community of print service providers to understand the opportunities that may exist for them in this segment.”