It's important to ensure the colours in your printed graphics stay bold and true throughout the duration of the installation – your customers will rely on it – and there is a great deal of science behind accurately predicting the speed of ageing outdoors.

Much of the methodology used for these predictions concerns screen printing, owing to its popularity for outdoor-durable graphics, and is based on how different combinations of ink and substrate degrade. Both real-time and accelerated-time weather testing has taken place to provide reliable expectations. Naturally, weather varies across the world – the closer to the equator, the more intense the Sun's damaging UV rays – and weathering data can now be regionalised to give more accurate predictions based on where the printed image will be used, rather than where it is produced.

These types of tests are not necessarily appropriate for inkjet printing. Because the same substrates are used, it has generally been assumed that inkjet-printed images have the same exterior durability as screen printing, but there are more factors at play. It's possible to achieve a greater ink deposit with screen inks than inkjet and, generally, the thicker the ink deposit, the more durable the ink layer.

Furthermore, traditional weathering methods use the standard method of measuring only solid ink areas. This method is only really useful for solid and spot colours – and most CMYK images today are not made up of solid areas of colour. Instead they are produced by varying ink coverage to create tones and substrate show-through, with an almost infinite number of colours trapping each other in tonal percentages. The traditional solid colour weathering method, therefore, is not applicable to process colour images in terms of accurate predictions of inkjet ageing.

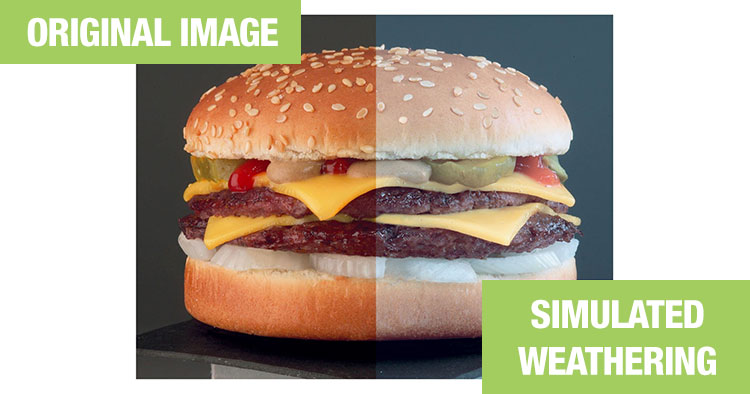

As time and technology has moved on, a new prediction method has been developed, called IMAGE. Nazdar has combined years of colour management experience with extensive real-time and accelerated weathering data on full tonal ranges of CMYK colours and colour traps, resulting in IMAGE colour profiles that provide an accurate visual prediction of how process colour images will fade.

The IMAGE process has significant potential for improvements at various stages of graphics production. Designers can use the profiles to decide on the use of colours in backgrounds, skin tones, foods and more, while IMAGE proofs can be generated to promote durable inks and substrates in sales presentations. Printers can also utilise the predictive software to create an artificially weathered panel when replacing part of a graphic to match the rest. IMAGE gives a realistic view of the future, enabling designers, print businesses and their customers to make an informed choice.

For more information on Nazdar and its comprehensive range of ink solutions, please click here

A whitepaper with full details on the IMAGE process can be downloaded here